A recombined decorative veneer

A technology for recombining decoration and veneer, which is applied to the jointing of wooden veneers, lamination devices, paper/cardboard layered products, etc., can solve the problems of environmental protection and wear resistance of paint-free boards, and achieve Effects of less smoke and toxic gas, enhanced performance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

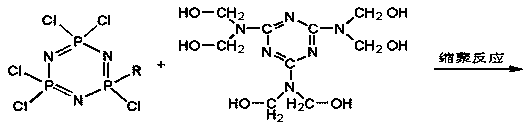

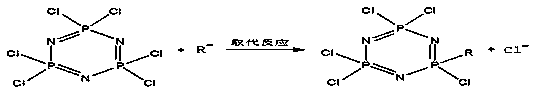

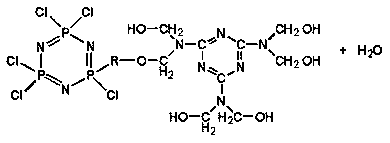

Method used

Image

Examples

Embodiment 1

[0046] A recombined decorative veneer, the manufacturing method of the veneer comprises the following steps:

[0047] a. Slicing: Slice the restructured decorative material into a restructured decorative veneer with a thickness of 0.35mm.

[0048] b. The first hot pressing: the weight of pasting on the back of the restructured decorative veneer is 20g / m 2 non-woven fabric. The hot pressing process is: pressure 0.5Mpa, temperature 110°C, time 60s.

[0049] c. Glue preparation: Add 5kg of tourmaline anion powder with a particle size of 800 mesh and anion count of 5000ions / cc in 100kg of melamine-modified urea-formaldehyde resin solution, AL 2 o 3 0.3kg, 5kg curing agent, and stir evenly. The preparation method of the curing agent is as follows: add 100 parts by mass of water into the reaction kettle, start stirring, raise the temperature to 40°C, add 20 parts of aluminum sulfate and 15 parts of p-toluenesulfonic acid, dissolve completely, cool down to room temperature and di...

Embodiment 2

[0061] A recombined decorative veneer, the manufacturing method of the veneer comprises the following steps:

[0062] a. Slicing: slice the restructured decorative material into a restructured decorative veneer with a certain thickness of 0.5mm.

[0063] b. The first hot pressing: the weight of pasting on the back of the restructured decorative veneer is 35g / m 2 kraft paper. The hot pressing process is: pressure 0.8Mpa, temperature 105°C, time 100s.

[0064] c. Glue preparation: add tourmaline anion powder 8kg, AL 2 o 3 0.5kg, 10kg of curing agent, release agent, etc., and stir evenly.

[0065] d. Manufacture of transparent wear-resistant surface film paper: The transparent wear-resistant surface paper is sequentially passed through ordinary glue and containing tourmaline powder, AL on a special production line 2 o 3 The urea-formaldehyde resin glue solution, and drying, the two dipping amounts are 100% respectively; the quantitative amount of the wear-resistant surface ...

Embodiment 3

[0076] The recombined decorative veneer is prepared by the following steps:

[0077] 1) Slicing: slice the restructured decorative material into a restructured decorative veneer with a thickness of 1.00mm;

[0078] 2) The first hot pressing: on the back of the recombined decorative veneer, apply the flexible reinforcing material through the first hot pressing; the thickness of the flexible reinforcing material is 0.15mm; the first hot pressing process is: temperature 120 ° C, pressure 1.0 Mpa, time 50s;

[0079] 3) Glue preparation: add tourmaline negative ion powder, AL 2 o 3 , curing agent and release agent, and stir evenly; the mass ratio of amino formaldehyde resin solution to curing agent and tourmaline powder is 100:10:10, amino formaldehyde resin solution to AL 2 o 3 The mass ratio is 100:1;

[0080] 4) Manufacture of transparent wear-resistant surface film paper: The transparent wear-resistant surface paper is dipped sequentially through ordinary glue solution for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com