Copper surface organic solder preservative and application thereof

A solder-preserving and organic technology, applied in the field of copper surface treatment in the PCB industry, can solve problems such as uneven film formation, achieve good anti-oxidation, good application prospects, and improve uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

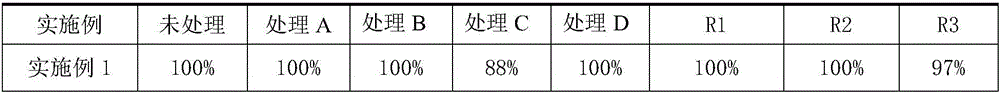

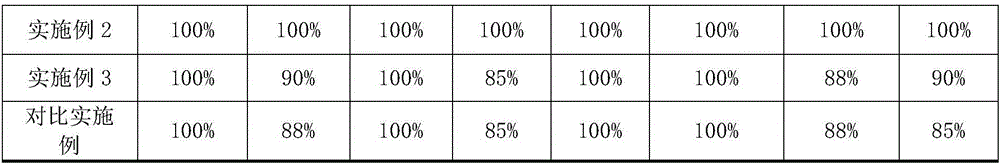

Embodiment 1

[0019] Preparation of organic flux for copper surface:

[0020] Heat 0.8kg of solution HP-MU (Shenzhen Tianxi Technology Development Co., Ltd.) containing organic film-forming substances to 40°C, add 16g of regulating additive n-octanoic acid, stir and mix evenly, add 0.5g of 2-amino-2-formazan base-1-propanol to obtain an organic soldering flux for the copper surface with a pH value of 3.

Embodiment 2

[0022] Preparation of organic flux for copper surface:

[0023] With 0.8kg of solution HPX-MU (Shenzhen Tianxi Technology Development Co., Ltd.) containing organic film-forming substances, the temperature was raised to 36°C, and 16g of regulating auxiliary agent oleic acid was added, stirred and mixed evenly, and 4g of 2 -Amino-2-methyl-1-propanol aqueous solution to obtain an organic soldering flux for the copper surface, with a pH value of 2.8.

Embodiment 3

[0025] Preparation of organic flux for copper surface:

[0026] With 0.8kg solution HF-MU (Shenzhen Tianxi Science and Technology Development Co., Ltd.) that contains organic film-forming substances, heat up to 40°C, add 40g of regulating auxiliary agent n-octanoic acid, stir and mix evenly, add 2.5g of 65% mass concentration 2-(butylamino) ethanol aqueous solution, obtains the copper surface organic flux that pH value is 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com