Welding device and welding method for solving high nitrogen steel welding porosity and improving joint strength

A technology of joint strength and welding device, which is applied in welding/welding/cutting items, welding equipment, laser welding equipment, etc. Improve mechanical properties and reduce porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

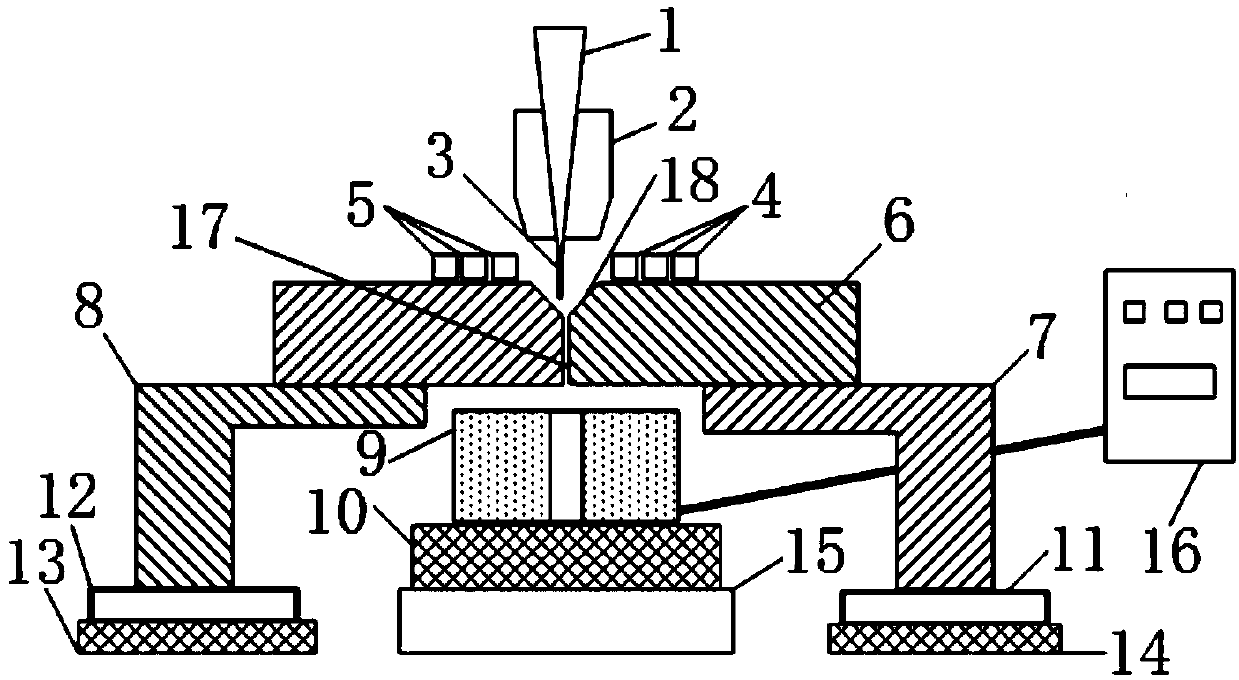

[0040] The welding method of the above-mentioned device is specifically carried out in accordance with the following steps:

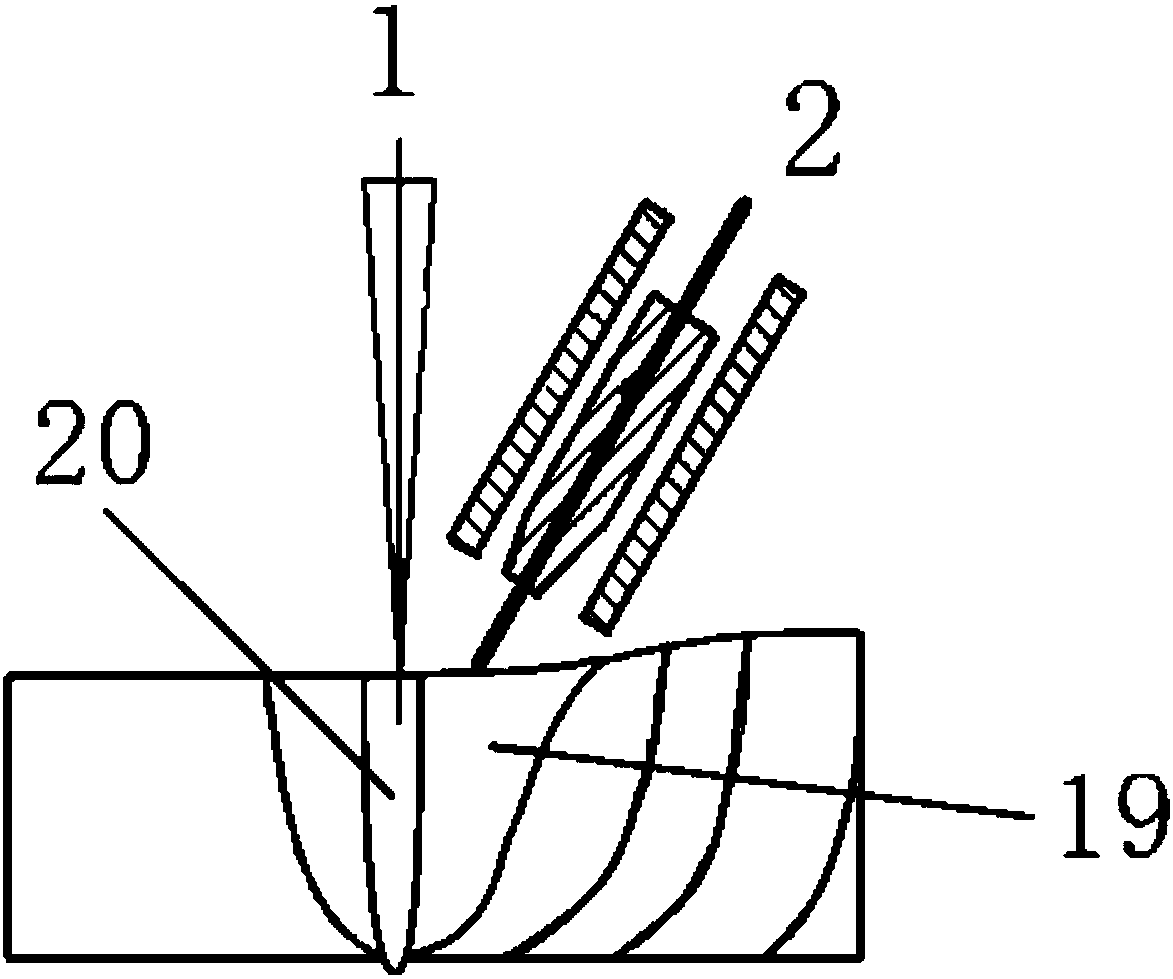

[0041] Step 1: Install and debug the device, clamp two welded workpieces 6 made of high-nitrogen steel with a thickness of 8.0mm and a nitrogen content of 0.5-0.7% on the first workpiece support plate 7 and the second On the workpiece support plate 8;

[0042] Step 2: Open the water inlet valves of the first water-passing copper pipe 4 and the second water-passing copper pipe 5, adjust the circulating water temperature in the first water-passing copper pipe 4 and the second water-passing copper pipe 5 to 15°C, and the circulating water flow rate 12L / min; turn on the excitation power supply 16, start the power supply of the CNC workbench, YAG laser and welding torch 2 synchronously, the YAG laser emits a laser beam 1, and the laser beam 1 is irradiated vertically on the front of the welding workpiece 6 to form a laser keyhole 20; welding torch 2 Welding...

Embodiment 2

[0045] The welding method of the above-mentioned device is specifically carried out in accordance with the following steps:

[0046] Step 1: Install and debug the device, clamp two welded workpieces 6 made of high-nitrogen steel with a thickness of 8.0mm and a nitrogen content of 0.5-0.7% on the first workpiece support plate 7 and the second On the workpiece support plate 8;

[0047] Step 2: Open the water inlet valves of the first water-passing copper pipe 4 and the second water-passing copper pipe 5, adjust the circulating water temperature in the first water-passing copper pipe 4 and the second water-passing copper pipe 5 to 10°C, and the circulating water flow rate 15L / min; turn on the excitation power supply 16, start the power supply of the CNC workbench, YAG laser and welding torch 2 synchronously, CO 2 The laser emits a laser beam 1, and the laser beam 1 is vertically irradiated on the front of the welding workpiece 6 to form a laser keyhole 20; the welding torch 2 pe...

Embodiment 3

[0050] The welding method of the above-mentioned device is specifically carried out in accordance with the following steps:

[0051] Step 1: Install and debug the device, clamp two welded workpieces 6 made of high-nitrogen steel with a thickness of 8.0mm and a nitrogen content of 0.5-0.7% on the first workpiece support plate 7 and the second On the workpiece support plate 8;

[0052] Step 2: Open the water inlet valves of the first water-passing copper pipe 4 and the second water-passing copper pipe 5, adjust the circulating water temperature in the first water-passing copper pipe 4 and the second water-passing copper pipe 5 to 20°C, and the circulating water flow rate 10L / min; turn on the excitation power supply 16, start the power supply of the CNC workbench, YAG laser and welding torch 2 synchronously, the semiconductor laser emits a laser beam 1, and the laser beam 1 is vertically irradiated on the front of the welding workpiece 6 to form a laser keyhole 20; welding torch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com