Experiment method for realizing in-situ observation on inclusion in bearing steel liquid

An experimental method and bearing steel technology, applied in the field of steel inclusion control, can solve the problems of unresolved, high electron beam temperature, deformation, etc., and achieve the effects of convenient and uniform heating, reliable observation results, and simple experimental methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] After sampling from the high-end bearing steel finished product, the steps of this embodiment are as follows:

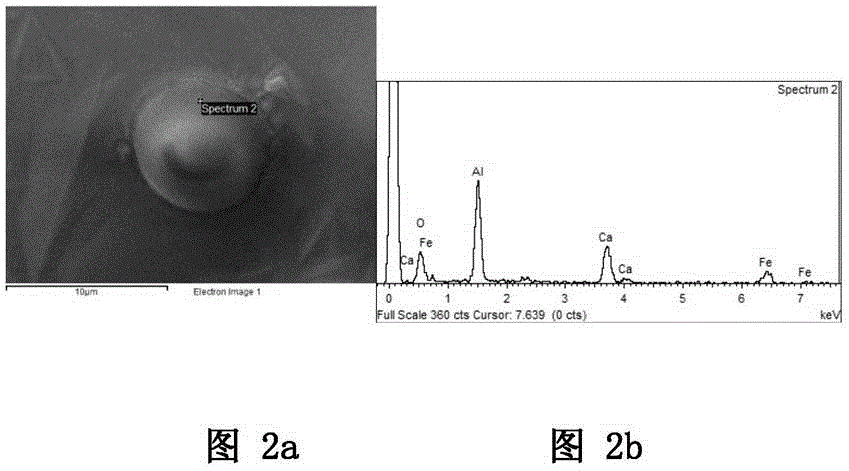

[0053] 1) A cylindrical sample processed by wire cutting of the bearing steel sample, the sample diameter is 5mm, and the height is 3mm. After the sample is polished by sandpaper, it is placed in the heating chamber of a high-temperature confocal laser microscope, and the sample is placed in an alumina crucible. Inside, the chamber is evacuated and fed with a pure argon flow to protect the sample from oxidation.

[0054] 1) Heat the sample to 1250°C at a heating rate of 120°C / min, then slowly heat the sample at a heating rate of 25°C / min until the upper surface is completely melted, and then rise to the highest temperature at a rate of 25°C / min 1500°C, heat preservation at the highest temperature for 20 seconds, observe the inclusion movement and collision behavior at a 200-fold magnification during the heat preservation process, and then rapidly cool to 950°C...

Embodiment 2

[0058] After sampling from the high-end bearing steel finished product, the steps of this embodiment are as follows:

[0059] 1) A cylindrical sample processed by wire cutting of the bearing steel sample, the sample diameter is 6 mm, and the height is 4 mm. After the sample is polished by sandpaper, it is placed in the heating chamber of a high-temperature confocal laser microscope, and the sample is placed in an alumina crucible. Inside, the chamber is evacuated and fed with a pure argon flow to protect the sample from oxidation.

[0060] Heat the sample to 1200°C at a heating rate of 140°C / min, then slowly heat the sample at a heating rate of 30°C / min until the upper surface is completely melted, and then rise to a maximum temperature of 1420°C at a rate of 30°C / min , hold at the highest temperature for 40 seconds, observe the inclusion movement and collision behavior at a 50-fold magnification during the holding process, and then rapidly cool to 1000°C at a cooling rate of ...

Embodiment 3

[0064] After sampling from the high-end bearing steel finished product, the steps of this embodiment are as follows:

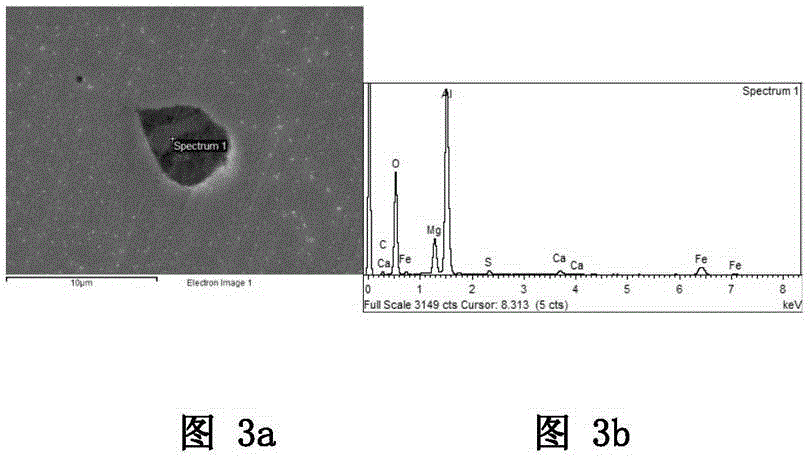

[0065] 1) A cylindrical sample processed by wire cutting of the bearing steel sample, the sample diameter is 4mm, and the height is 3mm. After the sample is polished by sandpaper, it is placed in the heating chamber of a high-temperature confocal laser microscope, and the sample is placed in a magnesium oxide crucible. Inside, the chamber is evacuated and fed with a pure argon flow to protect the sample from oxidation.

[0066] Heat the sample to 1250°C at a heating rate of 100°C / min, then slowly heat the sample at a heating rate of 20°C / min until the upper surface is completely melted, and then rise to a maximum temperature of 1450°C at a rate of 20°C / min , hold at the highest temperature for 30 seconds, observe the inclusion movement and collision behavior at a 500-fold magnification during the holding process, and then rapidly cool to 950°C at a cooling rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com