SiC annular floating-point type P+ structured junction barrier Schottky diode and preparation method thereof

A junction-barrier Schottky and floating-point technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. The effect of conducting conduction current, increasing conduction path, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

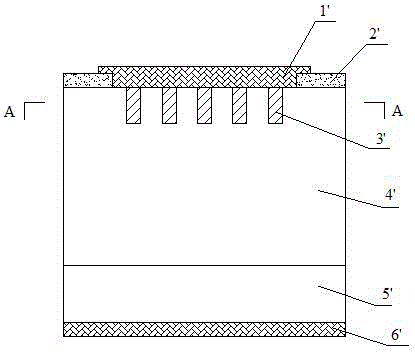

[0041] Step 1, such as Figure 5 As shown, the N-drift layer is epitaxially grown on the N+ silicon carbide substrate: first, the N+ type silicon carbide substrate 5 is cleaned by RCA standard; , Nitrogen ion doping concentration is 5×10 15 cm -3 N - For the epitaxial layer 4, the epitaxial process conditions are as follows: the temperature is 1580° C., the pressure is 100 mbar, the reaction gas is silane and propane, the carrier gas is pure hydrogen, and the impurity source is liquid nitrogen.

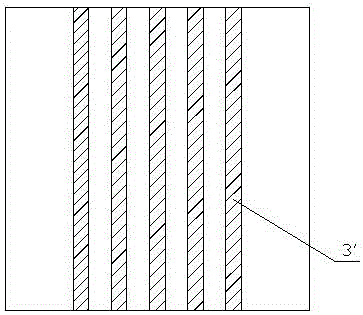

[0042] Step 2, such as Image 6 As shown, a ring-shaped floating-point type P+ implantation region 3 is formed on the N- epitaxial layer: (2.1) Deposit 2 μm of SiO 2 As a barrier layer for Al ion implantation in the P+ implantation area, and form the implantation window of the ring-shaped floating-point P+ implantation area 3 by photolithography and etching; (2.2) Perform aluminum ion implantation three times at a temperature of 400 ° C, and the The doses were 1.33×10 14 cm -2 ...

Embodiment 2

[0047] Step 1, such as Figure 5 As shown, the N-drift layer is epitaxially grown on the N+ silicon carbide substrate: first, the N+ type silicon carbide substrate 5 is cleaned by RCA standard; , nitrogen ion doping concentration is 1×10 15 cm -3 The epitaxy process conditions of the N- epitaxial layer 4 are as follows: the temperature is 1580° C., the pressure is 100 mbar, the reaction gas is silane and propane, the carrier gas is pure hydrogen, and the impurity source is liquid nitrogen.

[0048] Step 2, such as Image 6 As shown, a ring-shaped floating-point type P+ implantation region 3 is formed on the N- epitaxial layer: (2.1) Deposit 2 μm of SiO 2 As a barrier layer for Al ion implantation in the P+ implantation area, the implantation window of the ring-shaped floating-point P+ implantation area 3 is formed by photolithography and etching; (2.2) Perform aluminum ion implantation three times at a temperature of 500 ° C, implant The doses were 1.33×10 14 cm -2 , 8.2...

Embodiment 3

[0053] Step 1, such as Figure 5 As shown, the N-drift layer is epitaxially grown on the N+ silicon carbide substrate: first, the N+ type silicon carbide substrate 5 is cleaned by RCA standard; , nitrogen ion doping concentration is 2×10 15 cm -3 The epitaxy process conditions of the N- epitaxial layer 4 are as follows: the temperature is 1580° C., the pressure is 100 mbar, the reaction gas is silane and propane, the carrier gas is pure hydrogen, and the impurity source is liquid nitrogen.

[0054] Step 2, such as Image 6 As shown, a ring-shaped floating-point type P+ implantation region 3 is formed on the N- epitaxial layer: (2.1) Deposit 2 μm of SiO 2 As a barrier layer for Al ion implantation in the P+ implantation area, the implantation window of the ring-shaped floating-point P+ implantation area 3 is formed by photolithography and etching; (2.2) Perform aluminum ion implantation three times at a temperature of 400 ° C, implant The doses were 1.33×10 14 cm -2 , 8.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com