Oxide-enhanced high heat input welding steel plate

A large heat input welding and oxide technology is applied in the field of oxide-enhanced large heat input welded steel plates, which can solve the problems of reduced strength of welding heat affected zone, waste of Fe-Ti alloy, and deterioration of toughness of welded coarse grain zone, etc. Achieve the effect of ensuring welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with preferred embodiments.

[0041] The concrete composition of embodiment 1~10# and comparative example 11~15# is shown in Table 1, produces according to following production process:

[0042] (1) During the smelting and casting process, smelting and casting into slabs are carried out in accordance with the composition range and element ratio relationship in the claims;

[0043] (2) In the heating process, the heating temperature of the slab is controlled between 1150 and 1250 ° C, and the holding time is 2 to 3 hours;

[0044] (3) In the rolling process, the cumulative rolling reduction rate is ≥ 80%;

[0045] (4) In the cooling process, directly water-cool after rolling, cool to 300-450°C at a rate of 5-30°C / s, and then air-cool to room temperature.

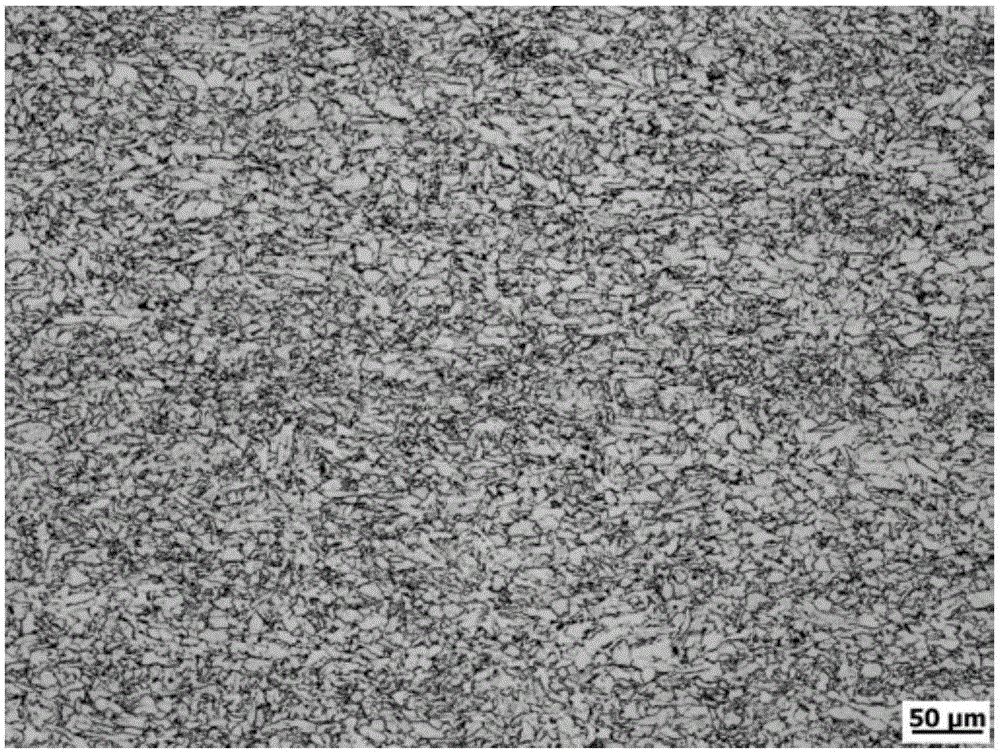

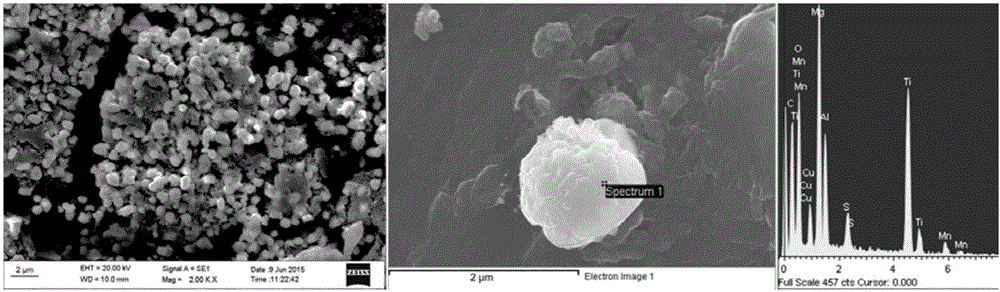

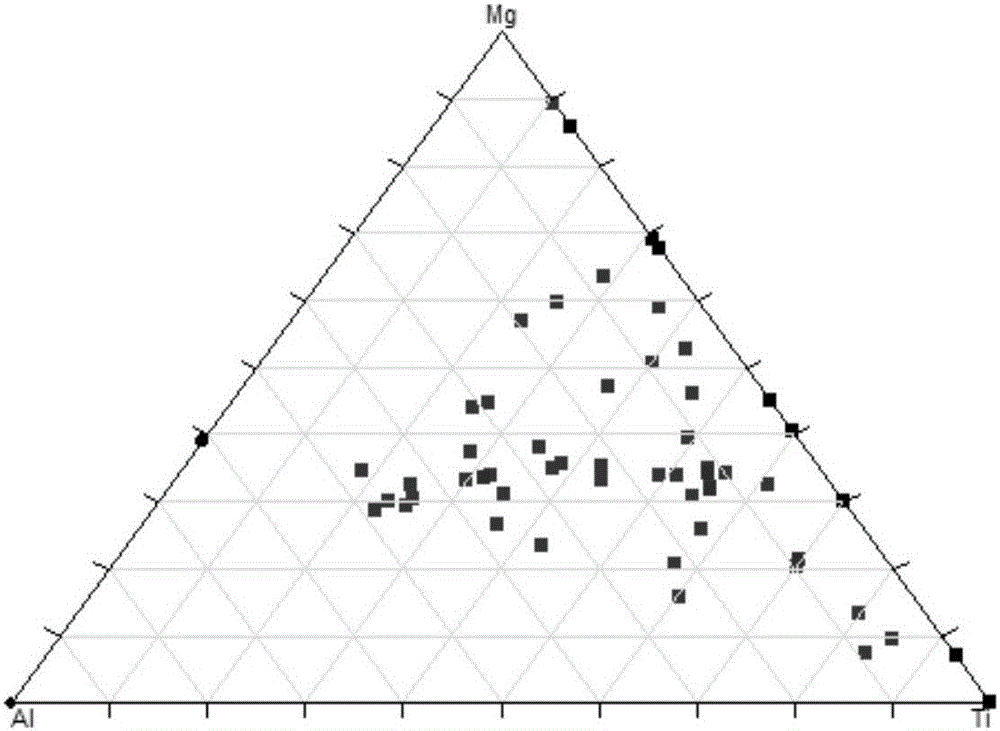

[0046] attached figure 1 It is a typical microstructure photo of the steel plate of the embodiment, showing that the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com