Welding heat treatment process for repair of long-term service P92 steel

A rework and process technology, applied in the field of rigid material repair, can solve problems such as failure to reach, poor impact toughness of welded joints, etc.

Pending Publication Date: 2021-07-06

国家能源集团泰州发电有限公司 +1

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] Due to the previous welding process, there is no special welding process for the replacement or repair of this type of material, which will lead to poor impact toughness of the welded joint, especially the heat-affected zone, which cannot meet the requirements of relevant standards

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0048] The main steam pipeline of a power plant with a service time of more than 50,000 hours was selected as the test material for this welding repair. Specifications: Material: P92.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| impact absorption energy | aaaaa | aaaaa |

Login to View More

Abstract

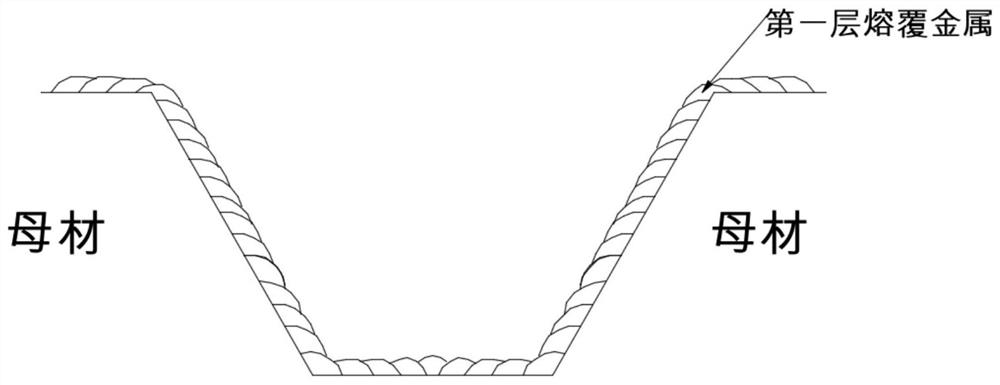

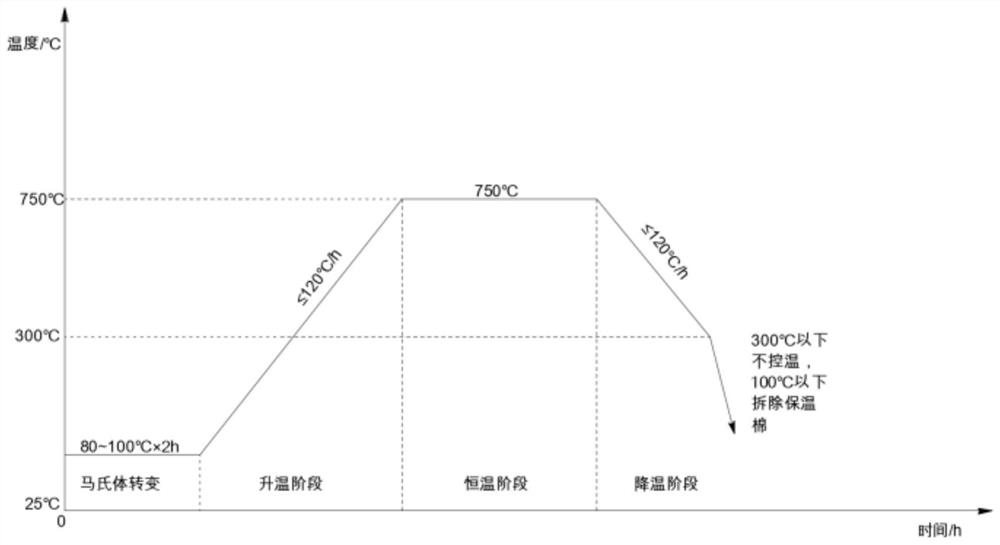

The invention relates to a welding heat treatment process for repair of long-term service P92 steel, and belongs to the technical field of steel material repair. In the welding process adopted by the invention, when the first layer of cladding metal in contact with the base metal is welded, the welding heat input is obviously increased. The main reason is that the peak temperature of heat circulation in the welding process is higher under the larger heat input. Under the influence of the welding temperature, large precipitates in a heat affected zone, especially in a coarse grain zone, are remelted at the temperature, fine dispersed carbides can be re-separated out from a saturated solid solution formed after the precipitates are remelted in subsequent cooling and heat treatment, and finally, the impact toughness of the heat affected zone is improved under the action of dispersion strengthening and second phase strengthening. By means of the process, the impact toughness of a welding joint, especially the welding heat affected zone, can be greatly improved compared with base metal, and application and popularization of the process are particularly important for guaranteeing the performance of the welding joint and further guaranteeing safe and stable operation of a unit.

Description

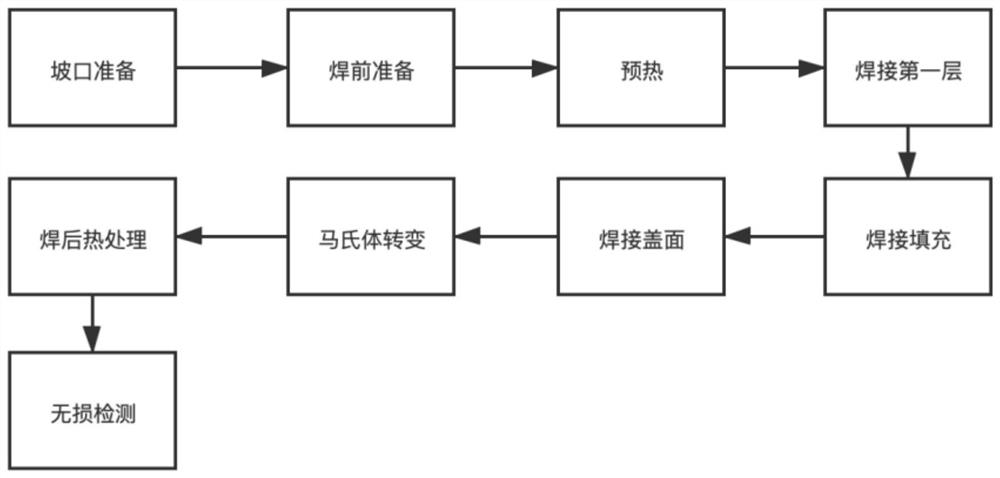

technical field [0001] The invention relates to a welding heat treatment process for the repair of long-serving P92 steel, which belongs to the technical field of rigid material repair. Background technique [0002] At present, in order to meet the operating requirements of the unit with high steam parameters, the materials for the high-temperature components of the unit need to meet the following requirements: better processing performance, lower thermal expansion coefficient, thermal fatigue resistance, good welding performance and high cost performance. P92 steel has better high-temperature strength and high-temperature oxidation resistance, lower linear expansion coefficient, better thermal fatigue resistance and less intergranular corrosion, and is the main material for high-temperature components of ultra-supercritical 1000MW units. [0003] However, the impact toughness of the base material is severely reduced after long-term service (generally more than 50000h). Thi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23P6/00B23K9/02B23K9/235

CPCB23P6/00B23K9/02B23K9/235

Inventor 周龙孙志强何利军周亚明汤淳坡刘同干尹少华郭小钢刘炜黄茂涛

Owner 国家能源集团泰州发电有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com