Steel plate with excellent low-temperature toughness in large heat-input weld heat affected zone and production method thereof

A technology of large heat input welding and heat-affected zone, applied in the field of low-alloy low-temperature steel plate manufacturing, can solve the problems of toughness deterioration, high construction cost, low production efficiency, etc., to ensure strength and low-temperature impact toughness, smelting and the effect of simple manufacturing process and improved welding efficiency

Active Publication Date: 2014-01-29

INST OF RES OF IRON & STEEL JIANGSU PROVINCE

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It can be seen that the traditional welding method has low production efficiency, which will result in long construction period and high construction cost.

[0004] For ordinary steel plates, the high heat input welding technology will bring the following two problems: 1) the toughness of the welding heat-affected zone (HAZ) deteriorates; 2) the sensitivity to welding cold cracks increases, which brings difficulties to on-site welding construction

Although the welding performance has been improved, it is difficult to smelt the steel with this technology. The quality and performance of the steel are affected by various factors such as the oxygen content in the molten steel before deoxidation, the amount of alloy added, the way of addition, and temperature control. The control window is narrow, and there is a slight deviation, and the welding performance of the steel plate will fluctuate greatly, resulting in a low product qualification rate, which brings difficulties to the market application of this type of steel

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

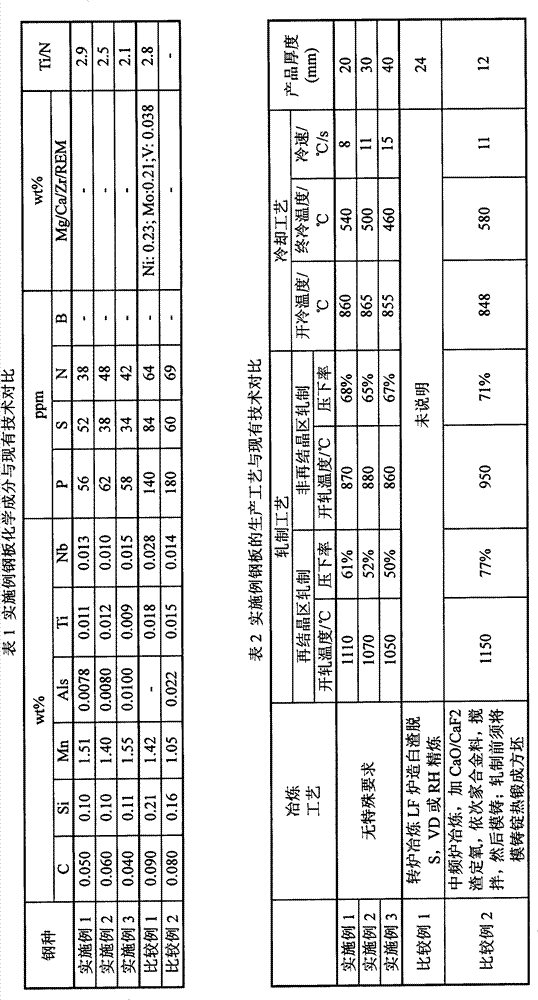

[0032] The specific embodiments are shown in Tables 1 to 3, wherein Table 1 is the chemical composition of the steel plate of the embodiment (comprising the comparative example), Table 2 is the production process of the embodiment (comprising the comparative example), and Table 3 is the weldability of the steel plate of the embodiment (comprising the comparative example). example).

[0033]

[0034]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Charpy impact | aaaaa | aaaaa |

Login to View More

Abstract

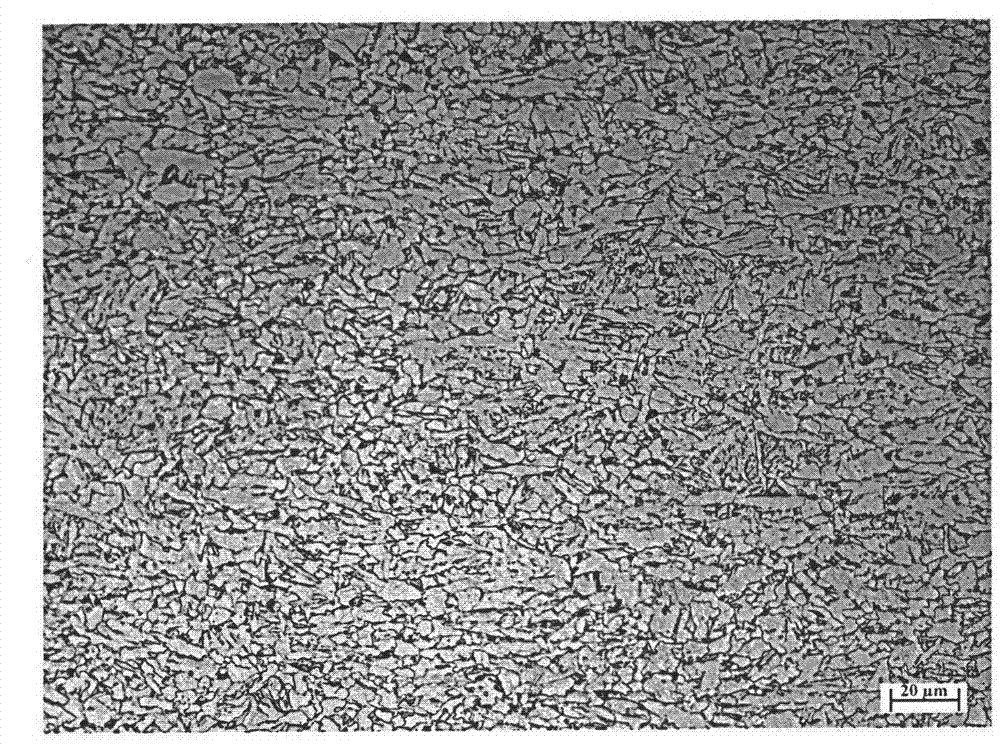

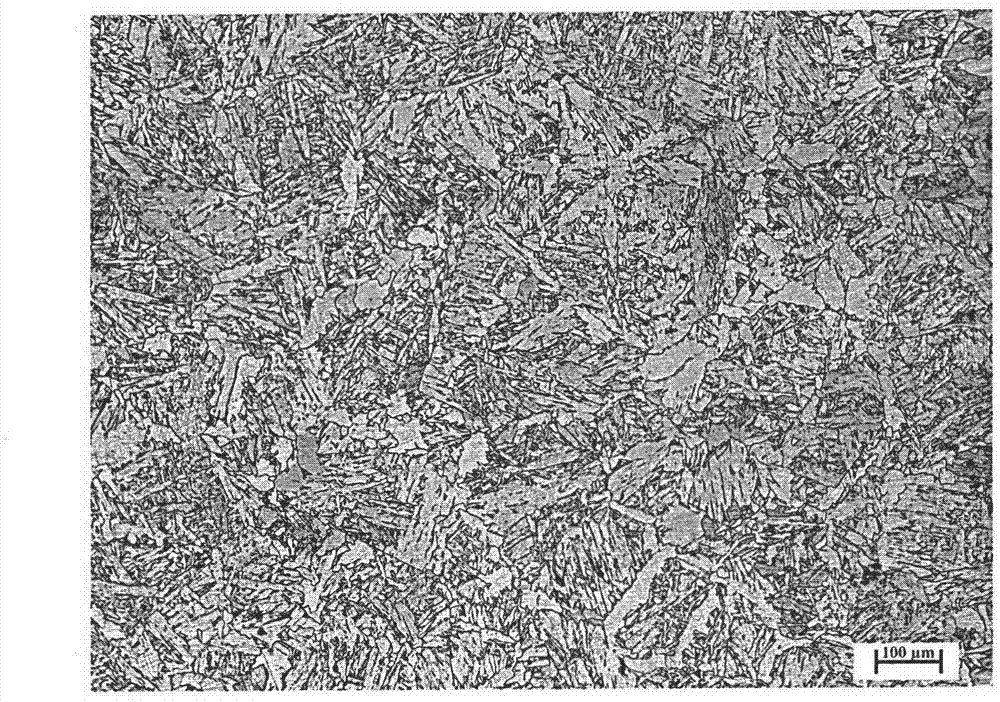

The invention discloses a steel plate with excellent low-temperature toughness in a large heat-input weld heat affected zone, which comprises the following chemical components in percentage by weight: 0.03-0.06% of C, 0.05-0.12% of Si, 1.30-1.60% of Mn, 0.007-0.015% of Nb, 0.007-0.015% of Ti, at most 0.01% of Al, 0.0035-0.0060% of N, at most 0.009% of P, at most 0.0052% of S and the balance of Fe and inevitable impurities. The invention adopts a low-C low-Si low-Al high-Mn-Nb microalloy composition, and the Ti / N ratio is 2.0-3.0. The production method adopts an advanced TMCP-AcC technique, so that the steel plate microstructure is an acicular ferrite of which the dimension is at most 10 mu m, and has excellent strength and low-temperature toughness; under the condition that the weld heat input is up to 200kJ / cm, the Charpy impact work of the weld heat affected zone at -20 DEG C is at least 179J; and the invention is applicable to ships, low-temperature pressure containers, ocean platforms and the like.

Description

technical field [0001] The invention belongs to the field of low-alloy low-temperature steel medium-thick plate manufacturing, and particularly relates to a steel plate with excellent low-temperature toughness in a large heat input welding heat-affected zone and a production method thereof. Background technique [0002] During the welding process of the steel plate, its structure and properties, especially the structure and properties of the welding heat-affected zone, will change. Usually when the welding heat input reaches 50-150kJ / cm, the toughness of the welding heat-affected zone will deteriorate sharply, even lower than the standard requirement value of the base metal. [0003] At present, the welding line energy that can be tolerated by steel used in ordinary ships, offshore platforms and other fields is about 30-40kJ / cm. The welding heat input used in construction practice is 25-30kJ / cm. According to the traditional welding method, for a 30mm thick plate, submerged...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/14C22C33/04C21D8/02

Inventor 潘鑫张宇李小宝郭慧英许红梅

Owner INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com