Fast recovery diode and manufacturing method thereof

A technology for recovering diodes and diodes, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of insignificant changes in local life mode, hardening of device recovery characteristics, and reduction of capture coefficients. The effects of surge and dynamic avalanche capability, soft recovery characteristics, and fast recovery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

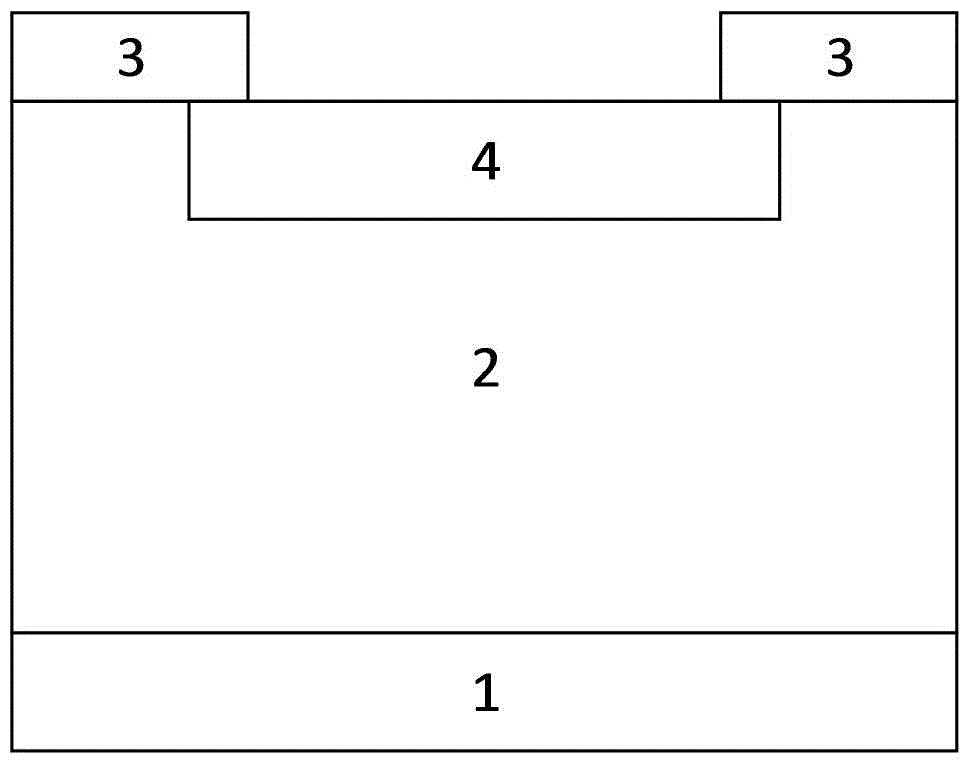

[0038] A. Initial oxidation: After cleaning the uniformly doped N-type silicon substrate, pass through the atmosphere of H2 and O2, in the temperature range of 900°C-1100°C, oxidation time of 1-10 hours, on the substrate An oxide layer 3 with a thickness of 8000-20000 angstroms is grown on the surface of the silicon wafer; figure 1 shown;

[0039] B. Forming the active area: on the uniformly doped N-type silicon substrate, the active area window is formed by applying glue, exposing, developing, etching, and removing the glue; figure 2 shown;

[0040] C. Forming a PN junction: In order to prevent implantation damage, a 300-500 Angstrom oxide layer is grown on the window of the active region as a masking layer, and the subsequent dose is 1e13cm -2 ~1e15cm -2 Boron ion implantation to form a boron ion implantation layer, and a 1-10um P+ region is formed under a nitrogen atmosphere at 1200°C; image 3 shown;

[0041]D. Forming a local lifetime control layer: use aluminum or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com