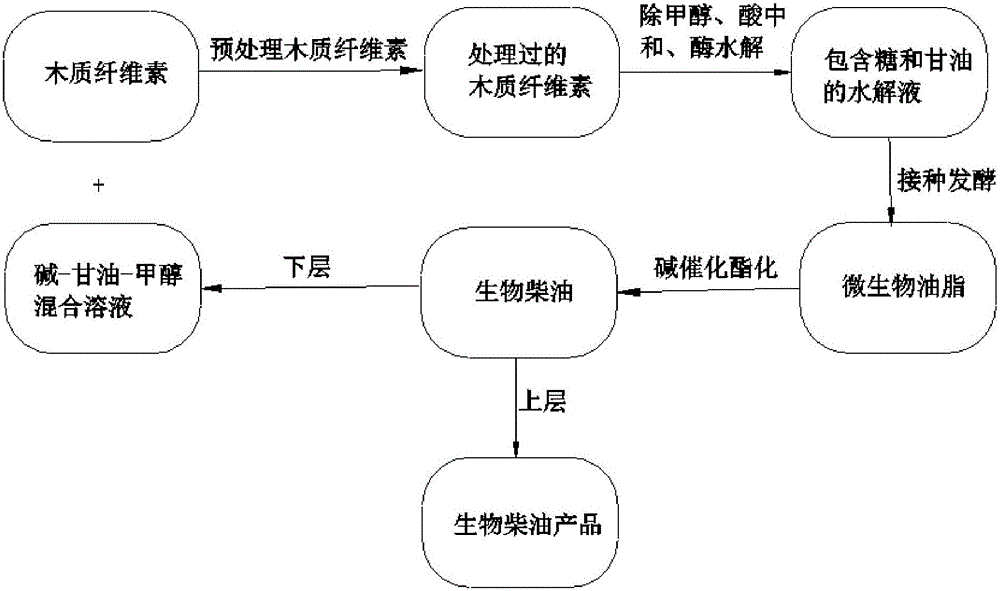

Method for producing biodiesel by means of lignocellulose material

A technology of lignocellulose and biodiesel, which is applied in the direction of biofuel, fat production, fatty acid production, etc., can solve the problems of low oil output, high production cost, and difficult resource utilization of by-products, so as to increase production and reduce reagent costs , Improve the effect of C/N ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

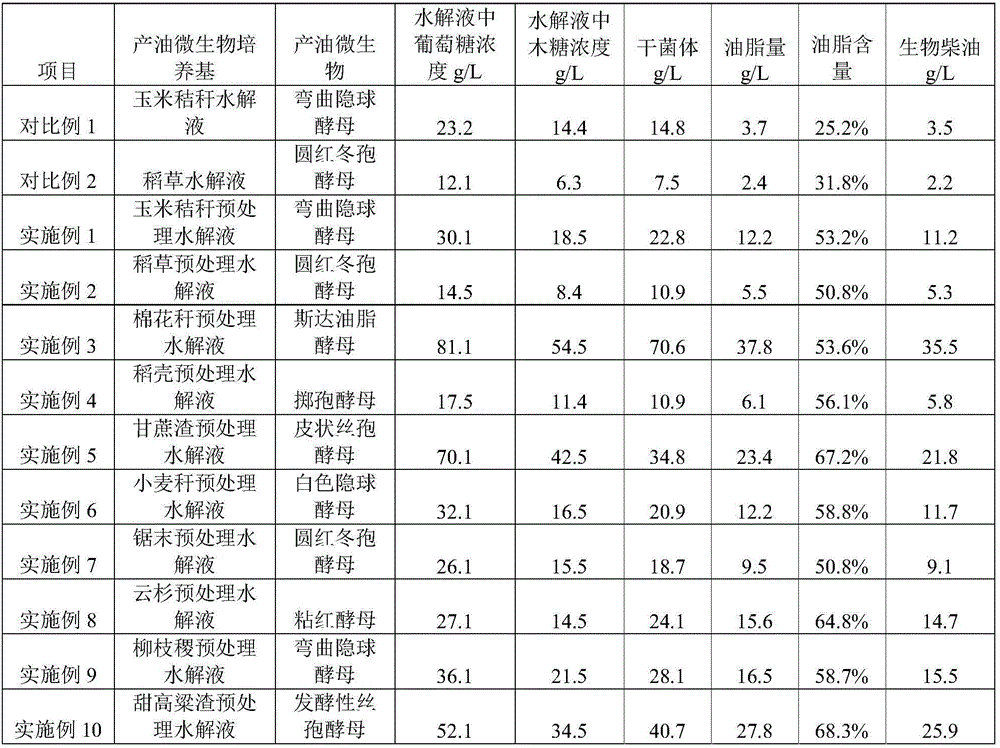

Embodiment 1

[0043] 1) Pretreatment of corn stalks and preparation of hydrolyzate: Weigh 50 g of corn stalks passed through a 40-mesh sieve, add 200 g of KOH-glycerin-methanol solution (KOH 2 g, glycerin 4 g, methanol 194 g), solid-liquid ratio 25% (w / w) , treated in a pretreatment tank at 180°C for 15 minutes; in-situ evaporation and condensation to recover methanol, adding water to adjust the solid-liquid ratio to 10% (w / w), adding H 2 SO 4 Adjust the pH to 4.8, add cellulase 15FPU / g, β-glucosidase 30CBU / g and xylanase 100U / g, hydrolyze in a water-bath shaker at 50°C and 200rpm for 48h to obtain a hydrolyzate; boil the hydrolyzate for 10min , vacuum filtration to obtain the hydrolyzed supernatant, in which the concentrations of glucose, xylose and glycerol were 30.1g / L, 18.5g / L and 15.8g / L respectively, and the C / N ratio was 72. After adjusting the pH to 6.0, it was extinguished at 121°C. After 20 minutes of bacteria, it is ready for use;

[0044] 2) Insert Cryptococcus curvatus ATCC20...

Embodiment 2

[0049] 1) Rice straw pretreatment and preparation of hydrolyzate: Weigh 20g of rice straw passed through a 20-mesh sieve, add 40g of KOH-glycerin-methanol solution (0.2g of KOH, 2g of glycerol, 37.8g of methanol), and the solid-to-liquid ratio is 50% (w / w ), treated in a pretreatment tank at 80°C for 2 hours; in situ evaporation to remove methanol, adding water to adjust the solid-liquid ratio to 5% (w / w), adding H 2 SO 4 Adjust the pH to 4.5, add cellulase 20FPU / g, β-glucosidase 40CBU / g and xylanase 100U / g, hydrolyze in a water-bath shaker at 50°C and 200rpm for 72h to obtain a hydrolyzate; boil the hydrolyzate for 10min , vacuum filtration to obtain the hydrolyzed supernatant, in which the concentrations of glucose, xylose and glycerin were 14.5g / L, 8.4g / L and 4.8g / L respectively, and the C / N ratio was 62. After adjusting the pH to 5.5, it was extinguished at 121°C Sterilize for 15 minutes and set aside;

[0050] 2) Insert Rhodosporidium toruloides AS2.1389 (purchased from...

Embodiment 3

[0055] 1) Pretreatment of cotton stalks and preparation of hydrolyzate: Weigh 10 g of cotton stalks passed through a 40-mesh sieve, add 100 g of NaOH-glycerin-methanol solution (2 g of NaOH, 2.5 g of glycerol, and 90 g of methanol), and the solid-to-liquid ratio is 10% (w / w ), treated in a pretreatment tank at 140°C for 2 hours; in situ evaporation to remove methanol, adding water to adjust the solid-liquid ratio to 25% (w / w), adding H 3 PO 4 Adjust the pH to 5.5, add cellulase 15FPU / g, β-glucosidase 30CBU / g and xylanase 100U / g, hydrolyze in a water-bath shaker at 50°C and 200rpm for 72h to obtain a hydrolyzate; boil the hydrolyzate for 10min , vacuum filtration to obtain the hydrolyzed supernatant, in which the concentrations of glucose, xylose and glycerin were 81.1g / L, 54.5g / L and 60.8g / L respectively, and the C / N ratio was 102. After adjusting the pH to 6.0, it was extinguished at 121°C. Sterilize for 15 minutes and set aside;

[0056] 2) Lipomycessstarkeyi AS2.1560 (pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com