A high-performance vanadium dioxide-based thermochromic composite material

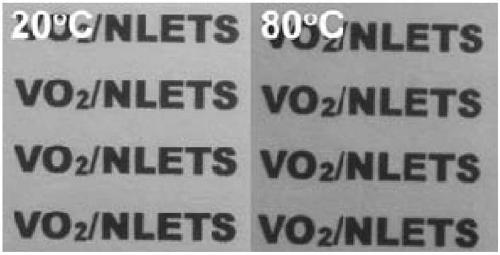

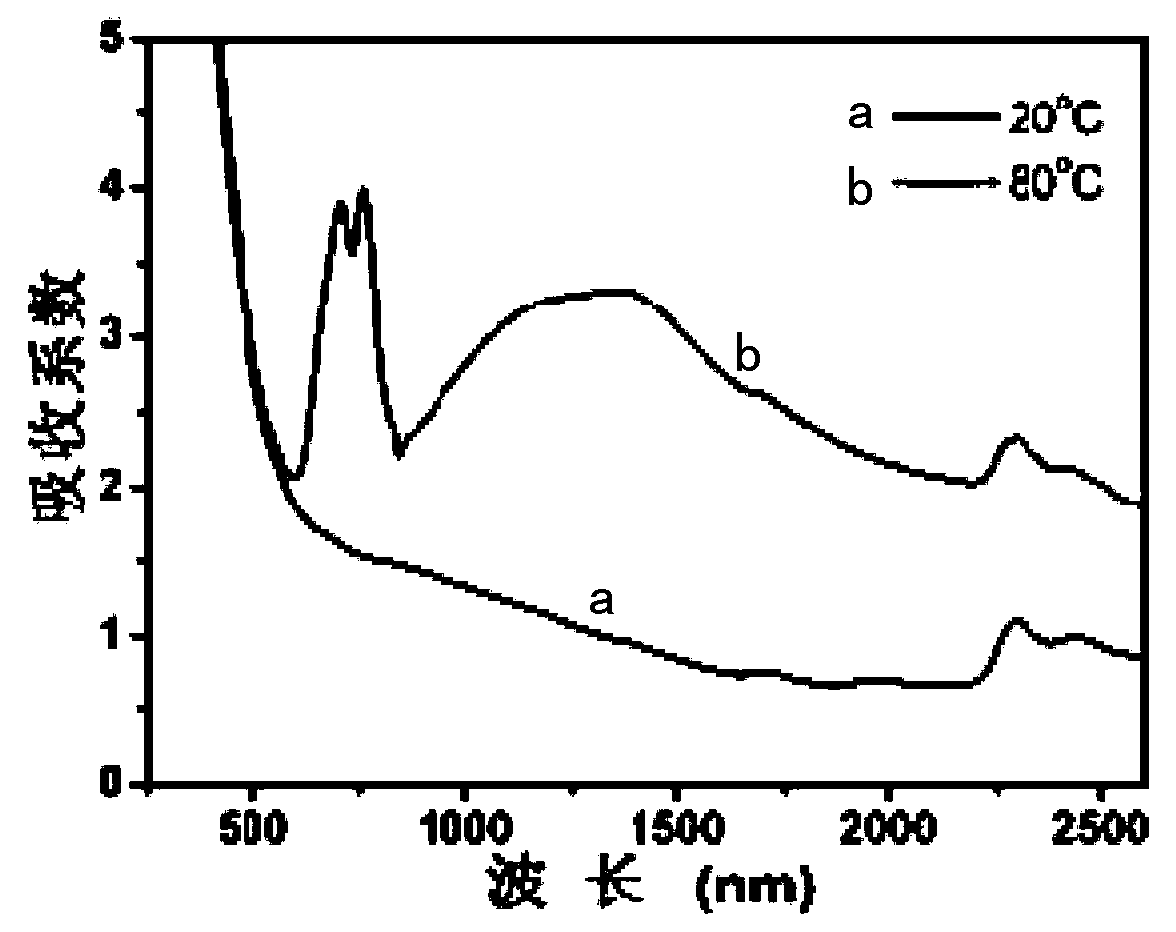

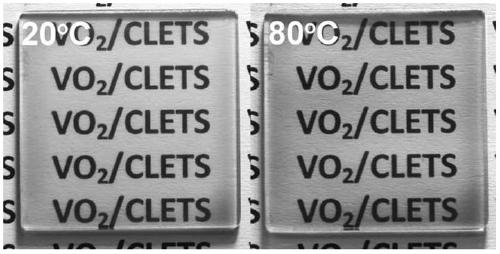

A thermochromic material, vanadium dioxide-based technology, applied in the direction of color-changing fluorescent materials, heat-sensitive coatings, chemical instruments and methods, etc., can solve the problems of inability to change visually, have no adjustment function, and do not help customers to demonstrate the adjustment effect , to achieve the effect of high total solar regulation rate and yellow hair color suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] First prepare 100ml of vanadium pentoxide solution containing 0.01mol / L, add 0.01g of oxalic acid and stir to form a uniform solution. Put the above solution into the reaction kettle and seal it, and react at 240°C for 24h. After cooling, take it out, centrifuge, wash and dry to obtain vanadium dioxide powder.

[0072] Take 0.5g of the vanadium dioxide nano-powder and 0.25g of polyvinylpyrrolidone prepared by the above-mentioned hydrothermal treatment, add them into 100g of ethanol, stir and ultrasonically disperse for 30min, transfer the dispersion to a ball mill tank, and ball mill for 1h under the condition of 900r / min to obtain two vanadium oxide ethanol dispersion; add 10g polyvinyl butyral to the above dispersion, stir until dissolved; continue to add 6.5g nickel perchlorate, 6g neopentyl glycol and 24g tetrabutylammonium bromide, stir until completely dissolved and Mix evenly; keep stirring the above-mentioned dispersion liquid at 90°C for 30 minutes to obtain a...

Embodiment 2

[0080] First prepare 100ml of vanadyl sulfate solution containing 0.01mol / L, add 5g of hydrazine monohydrate with a mass fraction of 10%, then use sodium hydroxide to titrate to pH 7 to form a suspension, filter and wash the precipitate and disperse it again in 100mL Stir in water to form a homogeneous solution. Put the above solution into the reaction kettle and seal it, and react at 260°C for 24h. Take it out after cooling, add 0.1g of glucose into the reactor, close the reactor, react at 180°C for 8h and cool to room temperature, centrifuge, wash and dry to obtain carbon-coated vanadium dioxide powder.

[0081] Take 1g of carbon-coated vanadium dioxide nanopowder and 0.5g of polyvinylpyrrolidone prepared by the above-mentioned hydrothermal treatment, add them into 100g of acetone, stir and ultrasonically disperse for 30min, then transfer the dispersion to a ball mill tank, and ball mill for 1h under the condition of 900r / min Obtain vanadium dioxide acetone dispersion liqui...

Embodiment 3

[0086] First prepare 100 ml of vanadium pentoxide solution containing 0.01 mol / L, add 0.005 g of tungsten trioxide and 0.5 g of hydrazine monohydrate with a mass fraction of 10%, and stir to form a uniform solution. Put the above solution into the reaction kettle and seal it, and react at 260°C for 24h. After cooling, take it out, centrifuge, wash and dry to obtain vanadium dioxide powder.

[0087] Take 0.5g of the vanadium dioxide nano-powder and 0.25g of polyvinylpyrrolidone prepared by the above-mentioned hydrothermal treatment, add them into 100g of acetone, stir and ultrasonically disperse for 30min, then transfer the dispersion to a ball mill tank, and ball mill for 1h under the condition of 900r / min to obtain two Vanadium oxide acetone dispersion; add 10g polymethyl methacrylate to the above dispersion, stir until dissolved; continue to add 4g cobalt bromide, 5g trimethylolpropane and 24g tetrabutylammonium bromide, stir until completely dissolved and Mix evenly; keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com