Thermochromic heat insulation coating and preparation method thereof

A heat-insulating coating and temperature-sensitive discoloration technology, which is applied in heat-sensitive coatings, reflective/signal coatings, radiation-absorbing coatings, etc., to achieve good economic benefits, good energy-saving effects, decorative effects, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

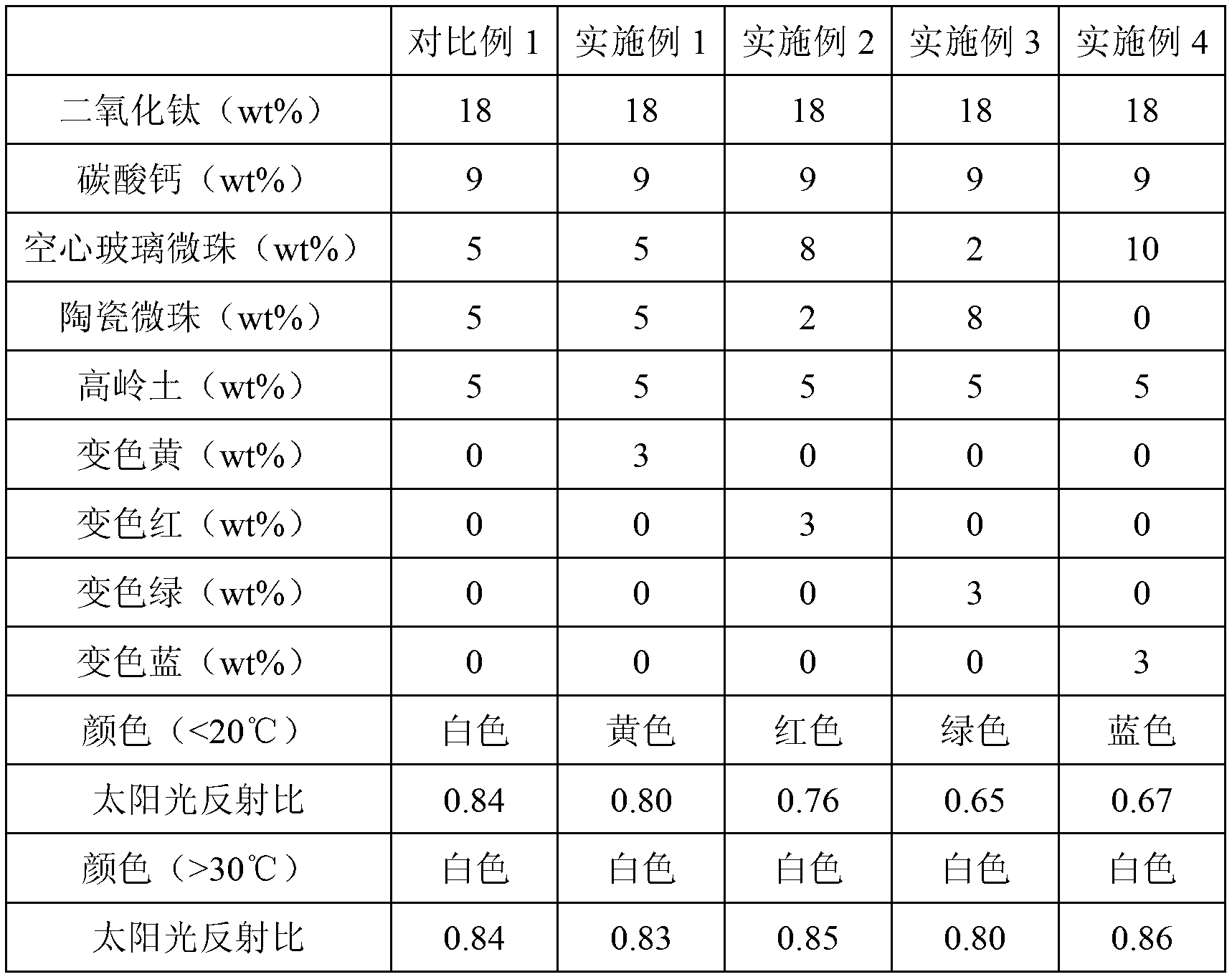

[0065] The present invention will be further described below in conjunction with specific examples. Percentages in the following comparative examples and examples are percentages by weight.

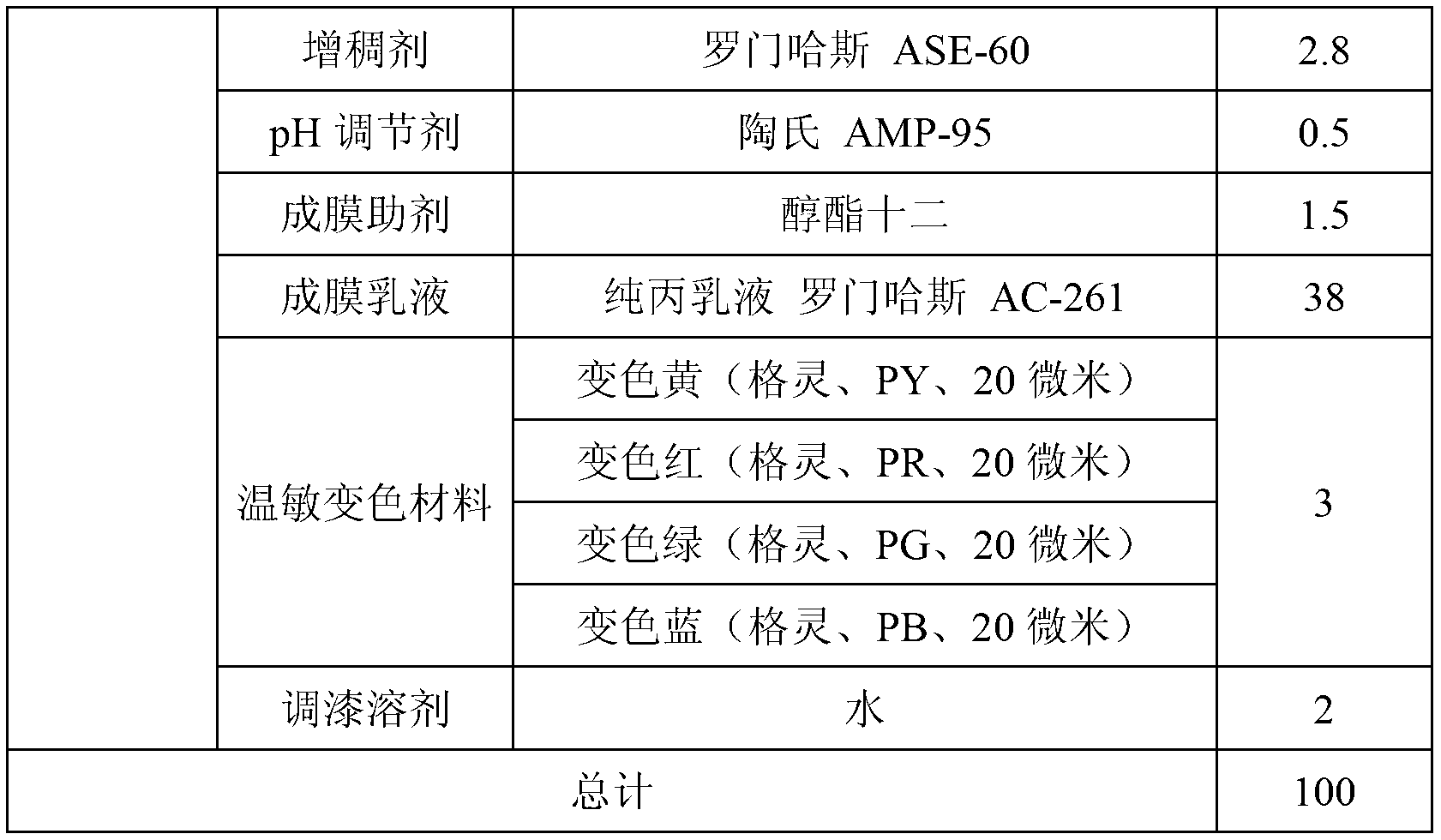

[0066] Preparation of temperature-sensitive color-changing heat-insulating coating

[0067] Pulping: The raw materials listed in Table 1 "Pulping Part" are ground by a high-speed disperser at a speed of 800rmp for 30 minutes to obtain a pulping part, which is sealed and stored after cooling.

[0068] Paint letdown: The raw materials listed in Table 1 "paint letdown part" were stirred by a stirring paddle at a low speed of 500rmp for 20 minutes to obtain the paint letdown part, which was sealed and stored at room temperature.

[0069] Mix the pulping part and the paint mixing part to obtain a temperature-sensitive color-changing heat-insulating coating.

[0070] Table 1 Composition of temperature-sensitive color-changing heat-insulating coating

[0071]

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com