Master batch capable of enhancing properties and melt strength of condensation polymer and preparation method thereof

A technology of melt strength and condensation polymers, applied in the field of polymers, can solve the problems of lack of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

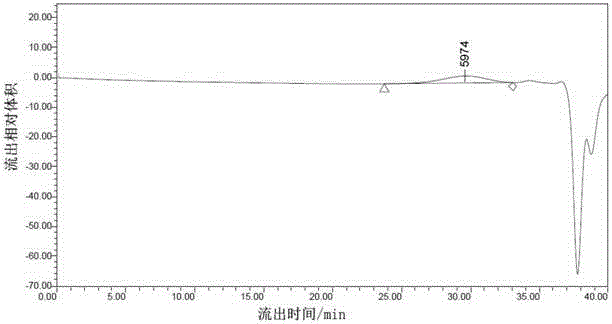

Embodiment 1

[0052] Select styrene as the first vinyl monomer, maleic anhydride as the second monomer containing G functional group for copolymerization, select azobisisobutyronitrile as the initiator, and xylene as the solvent, in a 25L reactor Solution polymerization was carried out at 60°C. The number average molecular weight of the final product is designed to be about 5000, and each molecular chain contains 10 maleic anhydride molecules on average, that is, there is one maleic anhydride monomer between about 3 to 4 styrene monomers, which is in line with the requirements for The law of branching degree response requirements. Then the feeding amount of maleic anhydride monomer is according to (N·M G ) calculation, it is 0.98kg; the feeding amount of styrene monomer is according to Calculated, it is 4.02kg. Since the molecular weight of the polymer is not high, 16.36kg of xylene solvent is selected, so the initial monomer [M] is about 2mol / L, so the number average degree of polymeri...

Embodiment 2

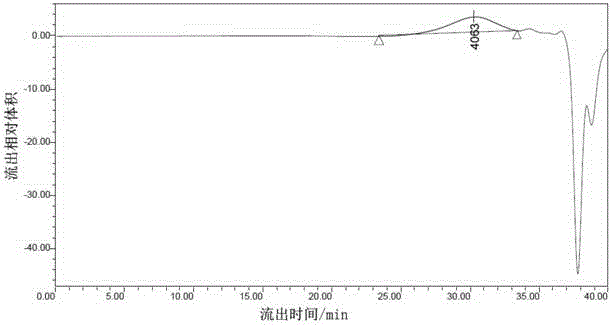

[0063] Choose methyl methacrylate as the first vinyl monomer, glycidyl methacrylate as the second monomer containing G functional group for copolymerization, choose benzoyl peroxide as the initiator, and polyvinyl alcohol as the suspending agent , Suspension polymerization was carried out at 60° C. in a 25 L reactor. The number average molecular weight of the final product is also designed to be about 5000, and each molecular chain contains 10 glycidyl methacrylate monomers on average, that is, there is 1 among about 3 to 4 methyl methacrylate monomers. The glycidyl methacrylate monomer meets the requirements for the degree of branching reaction. Then the feeding amount of glycidyl methacrylate monomer is according to (N·M G ) calculation, it is 1.42kg; the feeding amount of methyl methacrylate monomer is according to Calculated, it is 3.58kg. Select 0.1 kg of isooctyl 3-mercaptopropionate as the chain transfer agent. The initial monomer [M] is about 9.57mol / L, so the num...

Embodiment 3

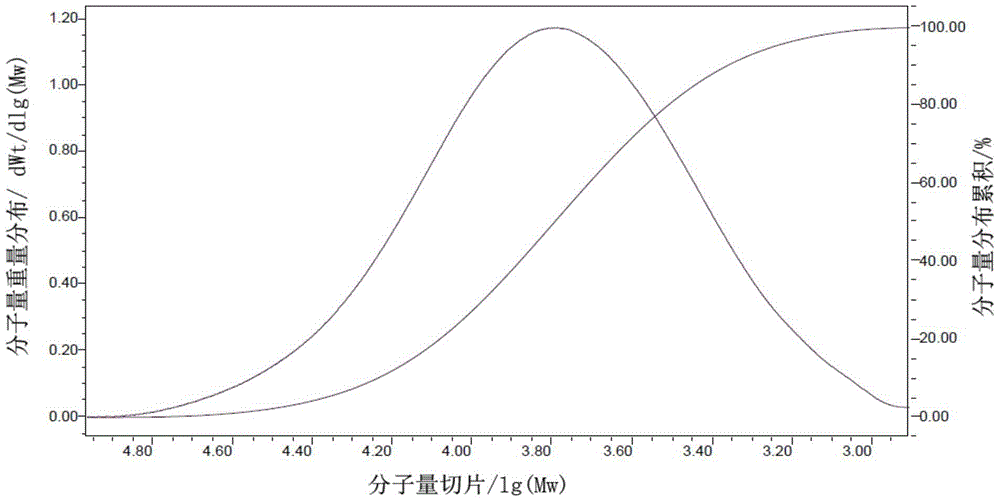

[0070] Styrene was selected as the first vinyl monomer, maleic anhydride was used as the second monomer containing G functional group for copolymerization, methyl ethyl ketone peroxide was selected as the initiator, and bulk polymerization was carried out in a 15lLIST device at 100°C. The number average molecular weight of the final product is designed to be about 3500, and each molecular chain contains 6 maleic anhydride molecules on average, that is, there is 1 maleic anhydride monomer between about 4 styrene monomers, which is in line with the requirement for branching. The law of response requirements. Then the feeding amount of maleic anhydride monomer is according to (N·M G ) calculation, it is 0.588kg; the feeding amount of styrene monomer is according to Calculated, it is 2.912kg. The initial monomer [M] is about 8.8mol / L, so the number average degree of polymerization 0.07kg of isooctyl 3-mercaptopropionate was selected as the chain transfer agent. Furthermore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com