A method for harmless disposal of high-arsenic heavy metal sludge

A technology for heavy metal sludge and disposal methods, applied in sludge treatment, chemical instruments and methods, fixed/solidified sludge treatment, etc., can solve the problems of high cost, unstable leaching toxicity, etc., and achieve loose storage conditions and solidification Good effect and low curing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

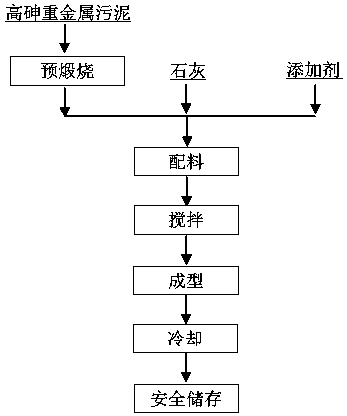

[0021] Such as figure 1 As shown, the harmless disposal method of high-arsenic heavy metal sludge, its specific steps are as follows:

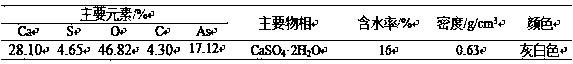

[0022] (1) Pre-calcination: Firstly, the high-arsenic heavy metal sludge with a moisture content of <40% (the main physical and chemical properties of the high-arsenic heavy metal sludge are shown in Table 1 and the leaching toxicity is shown in Table 2) at a temperature of 300°C. Calcined for 3h to obtain a calcined product;

[0023] Table 1

[0024]

[0025] (2) Ingredients: The calcined product obtained in step (1) is added with additives and lime according to the mass ratio of 80:12:8 and stirred evenly to obtain a mixed material; the additive is di Silica powder, bismuth trioxide (Bi 2 o 3 ), boron oxide (B 2 o 3 ), calcium oxide (CaO) and zinc oxide (ZnO) mixture; use a planetary mixer for stirring;

[0026] (3) Mold the mixed material obtained in step (3) to produce a solidified body, and store it safely after cooling; the mol...

Embodiment 2

[0032] Such as figure 1 As shown, the harmless disposal method of high-arsenic heavy metal sludge, its specific steps are as follows:

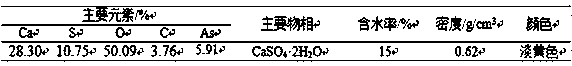

[0033] (1) Pre-calcination: Firstly, the high-arsenic heavy metal sludge with a moisture content of <40% (the main physical and chemical properties of the high-arsenic heavy metal sludge are shown in Table 3 and the leaching toxicity is shown in Table 4) at a temperature of 250°C. Calcined for 2h to obtain a calcined product;

[0034] table 3

[0035]

[0036] (2) Ingredients: Add additives and lime to the calcined product obtained in step (1) according to the mass ratio of 75:17:8 and stir evenly to obtain a mixed material; the additive is carbon dioxide with a mass ratio of 20:40:20:10:10 Silicon fume, bismuth trioxide (Bi 2 o 3 ), boron oxide (B 2 o 3 ), calcium oxide (CaO) and zinc oxide (ZnO) mixture; use a planetary mixer for stirring;

[0037] (3) Mold the mixed material obtained in step (3) to produce a solidified body, and s...

Embodiment 3

[0043] Such as figure 1 As shown, the harmless disposal method of high-arsenic heavy metal sludge, its specific steps are as follows:

[0044] (1) Pre-calcination: Firstly, the high-arsenic heavy metal sludge with a moisture content of <40% (the main physical and chemical properties of the high-arsenic heavy metal sludge are shown in Table 5 and the leaching toxicity is shown in Table 6) at a temperature of 250°C. Calcined for 1h to obtain a calcined product;

[0045] table 5

[0046]

[0047] (2) Ingredients: The calcined product obtained in step (1) is added with additives and lime according to the mass ratio of 70:20:10 and stirred evenly to obtain a mixed material; the additive is carbon dioxide with a mass ratio of 20:20:40:10:10 Silicon fume, bismuth trioxide (Bi 2 o 3 ), boron oxide (B 2 o 3 ), calcium oxide (CaO) and zinc oxide (ZnO) mixture; use a planetary mixer for stirring;

[0048] (3) Mold the mixed material obtained in step (3) to produce a solidified bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com