Hyperbranched polyamide modified chitosan quaternary ammonium salt microsphere for wastewater treatment and preparation method and application thereof

A technology of hyperbranched polyamide, chitosan quaternary ammonium salt, applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc. problem, to achieve the effect of good removal capacity, good adsorption removal, and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: the preparation of hyperbranched polyamide modified chitosan quaternary ammonium salt of the present invention is as follows:

[0057] Add 1g chitosan into 10mL N,N-dimethylacetamide, stir and swell at room temperature for 24h.

[0058] Dissolve 1.65g of trimesoyl chloride and 0.1875g of lithium chloride in 15mL of dry solvent N,N-dimethylacetamide in a three-necked flask equipped with an ice-water bath, a nitrogen inlet and outlet, and a magnet, and stir to make Fully dissolve for 0.5h, then add 0.5mL of acid-binding agent pyridine and 0.186g of ethylenediamine under ice bath conditions, stir the heterogeneous solution for 2h, remove from the ice bath and place in 35 o C conditions for 14h. After the reaction is over, add the hyperbranched polyamide generated by the reaction into the swollen chitosan at room temperature, react at room temperature for 24 hours, then add excess methyl iodide for reaction, react in the dark for 24 hours, discharge the mater...

Embodiment 2

[0063] Acetic acid aqueous solution: 2% (v / v, volume percentage concentration)

[0064] 0.8% (w / v%) hyperbranched polyamide modified chitosan quaternary ammonium salt solution: 10mL

[0065] Xylene 60mL

[0066] Tween85 (emulsifier) 3.6mL (6% of the volume of liquid paraffin)

[0067] Succindialdehyde (crosslinking agent) 0.4g

[0068] Emulsification time 4h

[0069] Cross-linking time 4h

[0070] temperature 50°C

[0071] Preparation Process:

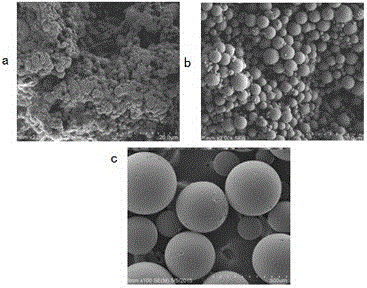

[0072] In a 250mL three-necked flask, add 60mL of xylene, add 3mL of Tween85 to it while stirring, stir for 5min, heat up to 50°C, add dropwise 10mL of 0.8% (w / v%) to the three-necked flask prepared in Example 1 The hyperbranched polyamide-modified chitosan solution was emulsified at 400rpm for 4 hours to prepare a W / O type inverse microemulsion. Then 0.4 g of succinaldehyde was added dropwise, and the cross-linking solidified for 4 hours, and then cooled to room temperature. The product was divided into a centrifuge tube and...

Embodiment 3

[0074] Acetic acid aqueous solution: 4.1% (v / v, ratio of acetic acid to water)

[0075] 1.3% (w / v) hyperbranched polyamide modified chitosan quaternary ammonium salt solution: 10mL

[0076] Cyclohexane: 60mL

[0077] Acrolein F-98 (emulsifier): 1.8mL (3% by volume of cyclohexane)

[0078] 2,7-Dimethyl-3-formyl-suberaldehyde (crosslinking agent): 0.8g

[0079] Emulsification time: 4h

[0080] Cross-linking time: 5h

[0081] Temperature: 50°C

[0082] Preparation Process:

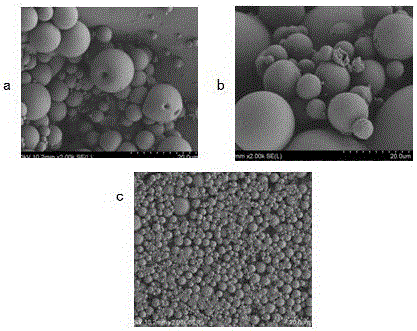

[0083] In a 250mL three-necked flask, add 60mL of cyclohexane, add 1.8mL of emulsifier F-98 to it while stirring, stir for 5min, raise the temperature to 50°C, add dropwise 10mL of 1.3% (w / v ) Modified chitosan quaternary ammonium salt solution, emulsified at 400rpm for 4h to prepare a W / O type inverse microemulsion. Then 0.8 g of 2,7-dimethyl-3-formyl-suberaldehyde was added dropwise, cross-linked and solidified for 5 hours, and then cooled to room temperature. The product was placed in a centrifuge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com