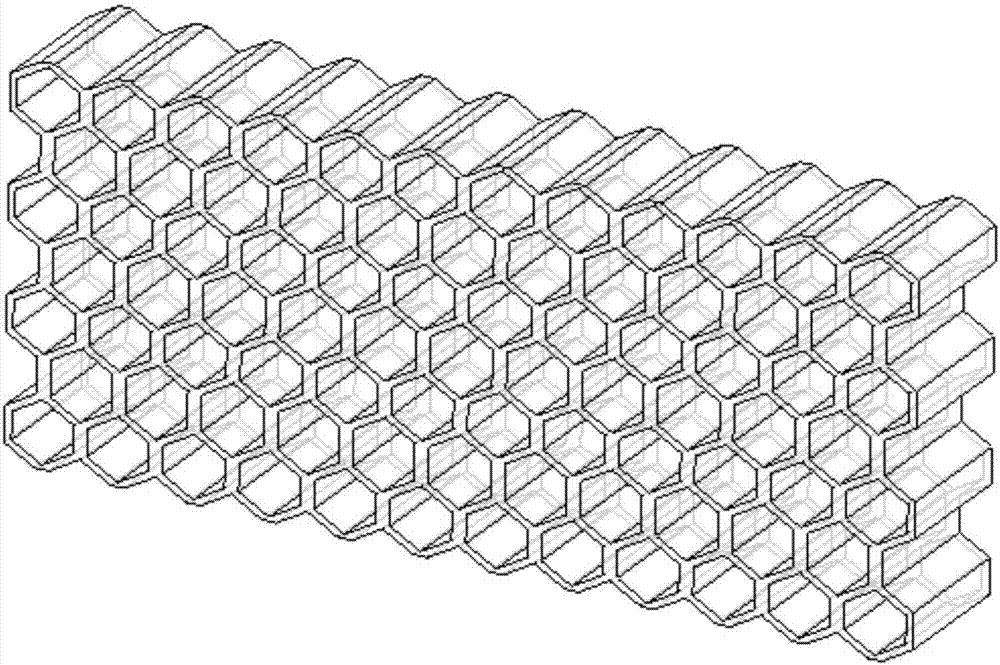

A kind of preparation method of tial base alloy honeycomb structure

A technology of honeycomb structure and base alloy, which is applied in the field of preparation of metal honeycomb structure, can solve the problems of high temperature deformation resistance of TiAl base alloy, difficulty in breaking through thin plate preparation technology, and a large number of welding seams in honeycomb walls, so as to improve mechanical properties and structural stability. performance, avoid casting defects, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

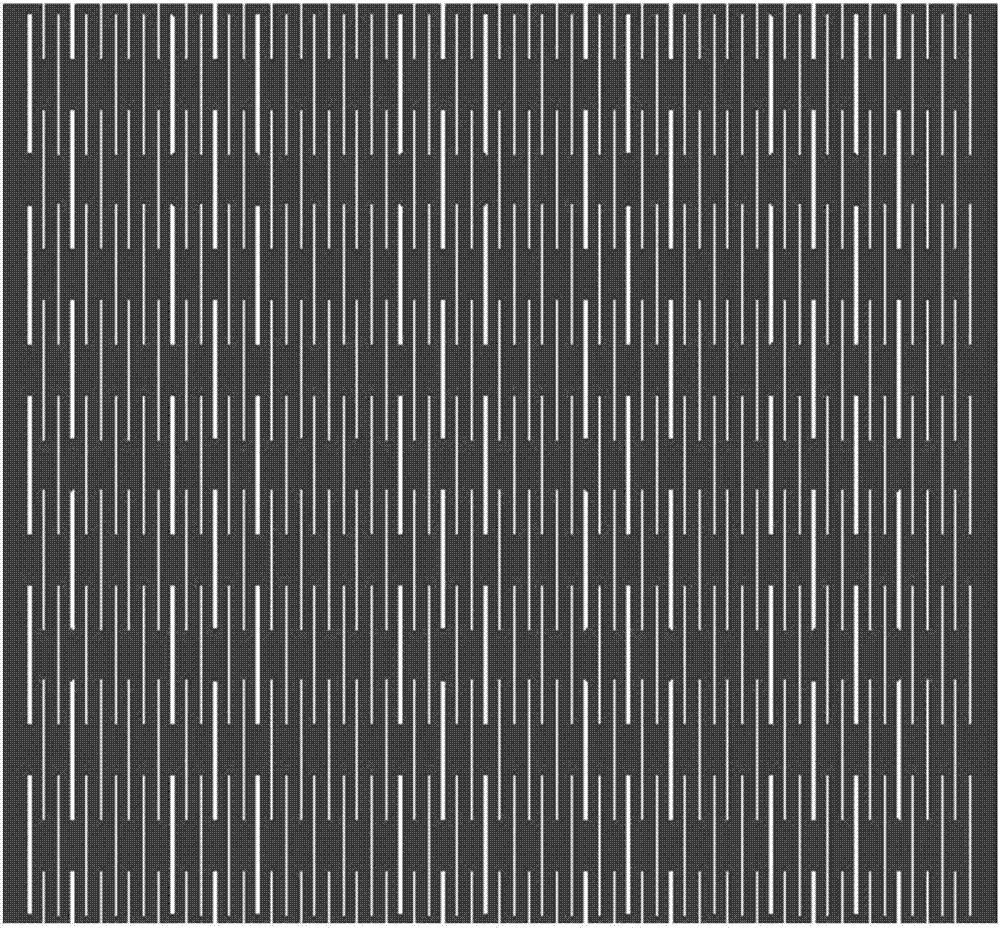

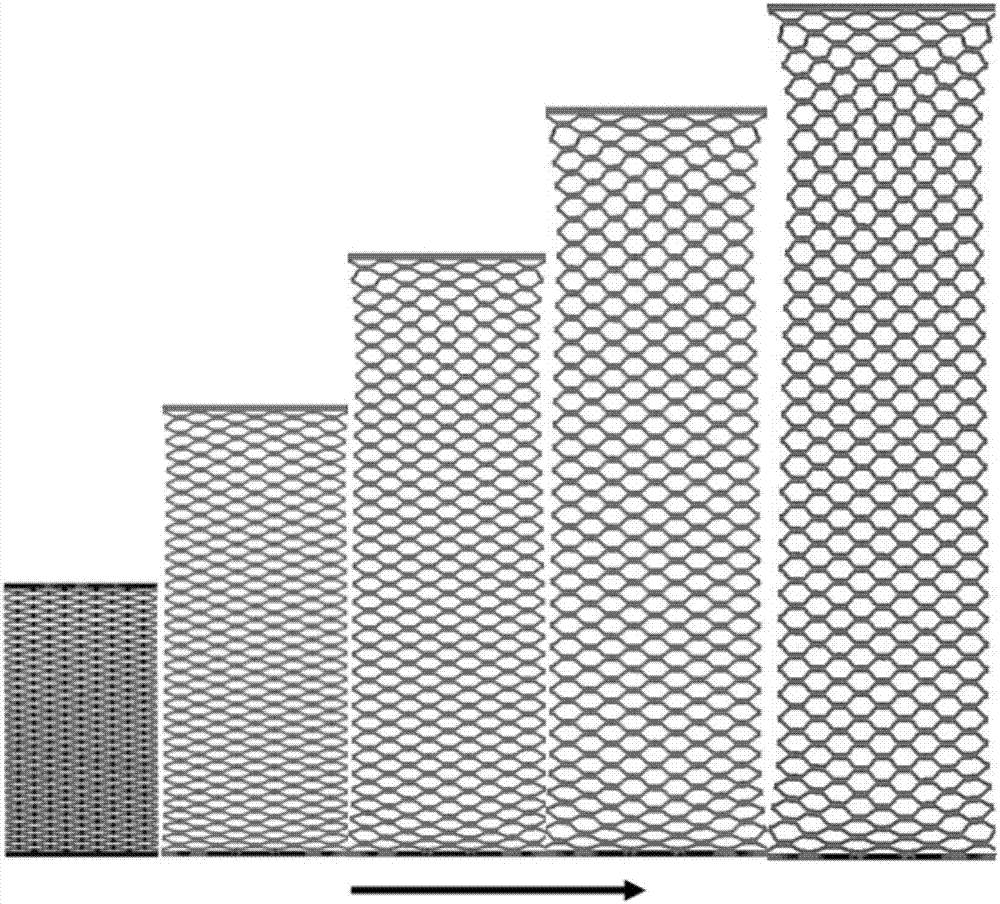

[0017] Specific embodiment 1: This embodiment is a method for preparing a TiAl-based alloy honeycomb structure, which is specifically carried out in the following steps:

[0018] 1. Forging: EDM cut the TiAl-based alloy billet into a cylindrical bar, and place it in a vacuum multifunctional hot pressing furnace. The vacuum degree is 10 -3 Under the conditions of Pa and heating rate of 5℃ / min~15℃ / min, the temperature is increased from room temperature to 1150℃~1300℃, and the vacuum degree is 10 -3 The temperature is 1150℃~1300℃ for 10min~60min, and then the vacuum degree is 10 -3 Pa, temperature is 1150℃~1300℃ and strain rate is 10 -1 s -1 ~10 -4 s -1 Open billet forging to a total deformation of 30% to 80% under the conditions of, and then the vacuum degree is 10 -3 Under the condition of Pa, it is cooled to 950℃~1100℃ with the furnace, and the vacuum degree is 10 -3 Hold for 2h~6h under Pa and temperature of 950℃~1100℃, when the vacuum degree is 10 -3 Under the condition of Pa, the...

specific Embodiment approach 2

[0023] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ratio of height to diameter of the cylindrical bar described in step 1 is 1:0.67. Others are the same as the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: The difference between this embodiment and specific embodiment one is that the extrusion ratio in step two is 2:1. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com