Fruit, vegetable and cyclodextrin supermolecule micro-powder, method for preparing same and application of fruit, vegetable and cyclodextrin supermolecule micro-powder

A cyclodextrin and supramolecular technology, which is applied in the field of fruit and vegetable-cyclodextrin supramolecular micropowder and its preparation, can solve the problems of reducing the effect of cyclodextrin, improper timing of cyclodextrin addition, and failure to achieve protection. Achieve good fluidity and dispersion and dissolution properties, protect unstable components, and timely inclusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

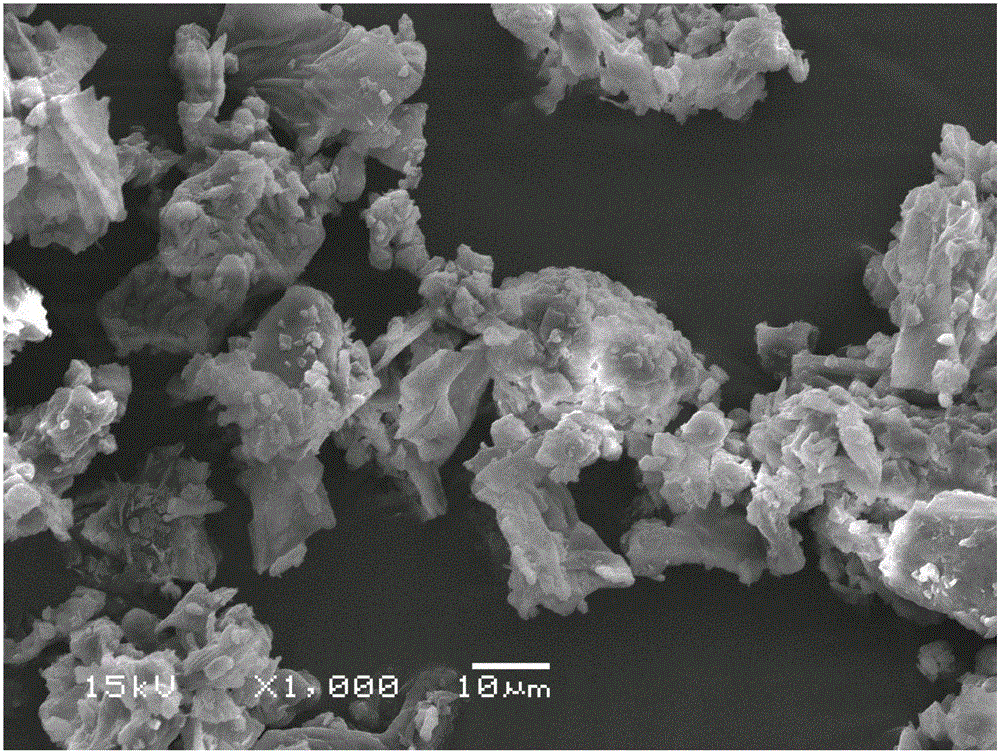

[0087] Embodiment 1. Get 20000g of fresh tomatoes and wash them, mix them with 1000g beta-CD, break them into coarse pulp with a crusher, then inject them into a colloid mill, adjust the fine grinding gear ratio to 5-15 μm, and grind them circularly for 0.5 hours to form a fine slurry. Material, 50 ℃ of vacuum dehydration in vacuum microwave drier, then room temperature vacuum drying 5 hours, pulverize, cross 100 mesh sieves to obtain 2011g bright red β-CD tomato micropowder.

[0088] Micropowder: TGA measured water content 5.16%, lycopene content 47.8mg / 100g; DTA spectrum (both measured in nitrogen atmosphere) a weak endothermic peak at 137°C after dehydration endothermic peak, no β-CD phase transition at 221°C Peak, exothermic peak at 328°C, the system is violently exothermic, ordinary tomato powder is exothermic peak at 202.85°C, and the system is violently exothermic at 336°C.

[0089] Instant tomato powder: Take 1000g of the above-mentioned fine powder, mix it with 120g o...

Embodiment 2

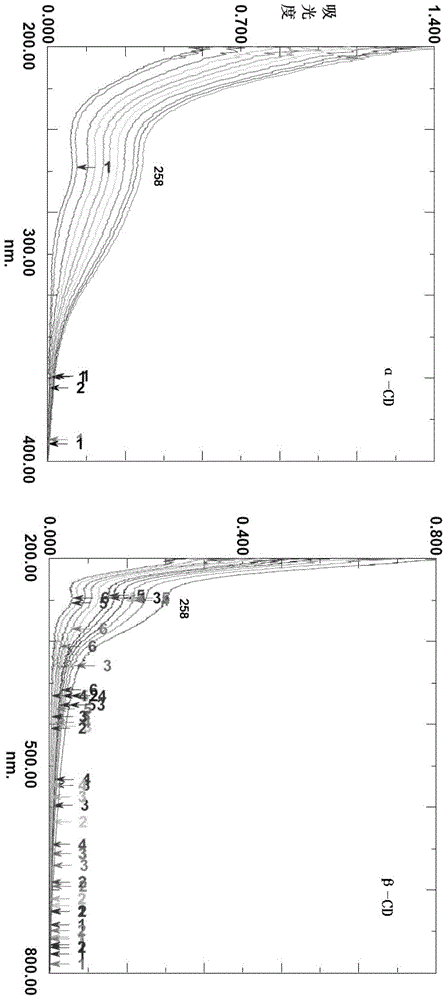

[0091] Embodiment 2. Take 3000g of fresh tomato and wash it, mix it with 100g α-CD, break it into a coarse slurry with a crusher, then pour it into a colloid mill, adjust the grinding gear ratio to 5-15 μm and grind it circularly for 0.5 hours, and after it becomes a fine slurry, come out Material, 50 ℃ of vacuum dehydration in vacuum microwave drier, then room temperature vacuum drying 5 hours, pulverize, cross 100 mesh sieves to obtain 248g bright red α-CD tomato micropowder.

[0092] Micropowder: Water content 6.61% as determined by TGA, lycopene content 183.2mg / 100g; DTA spectrum has no α-CD phase transition peak at 141°C after dehydration endothermic peak, and exothermic peak at 312°C.

Embodiment 3

[0093] Embodiment 3. Get 21000g of fresh day lily and wash, boil in water for 0.5 hours, mix with 3000gβ-CD and 2000ml water after draining the water, break into fine cubes with a crusher, then pour into a colloid mill, adjust the grinding gear ratio to 5- 15 μm circular grinding for 0.5 hours, after becoming a fine slurry, discharging, dewatering in a vacuum microwave dryer at 50°C under reduced pressure, then vacuum drying at room temperature for 5 hours, passing through a 100-mesh sieve to obtain 5770g of yellow β-CD day lily powder.

[0094] Micropowder: The water content is 8.33% by TGA; after the dehydration endothermic peak of the DTA spectrum (combined), a broad endothermic peak appears at 155°C, and the β-CD phase transition peak at 221°C disappears. The heat peak disappeared, and only a weak exotherm appeared at 338.90°C.

[0095] Instant daylily powder: Take 1000g of micropowder, mix it with 100g of lactitol, granulate with a little water, pass through a 40-mesh sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com