Process for heat treatment of high-performance Ti2AlNb powder alloy

A powder alloy, high-performance technology, applied in the field of heat treatment process of high-performance Ti2AlNb powder alloy, can solve the problems of unstable plasticity of AlNb alloy, and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

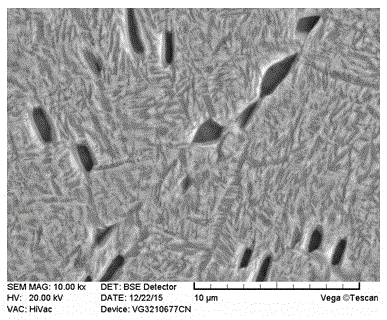

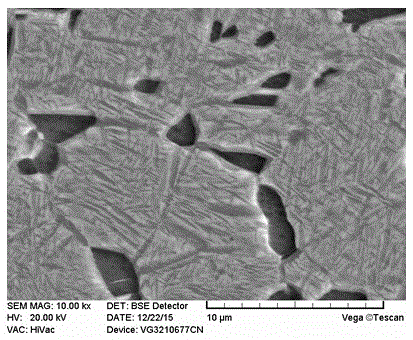

Image

Examples

Embodiment 1

[0018] A high performance Ti 2 The heat treatment process of AlNb powder alloy comprises the following steps:

[0019] 1) Using the plasma rotating electrode powder making equipment, under the condition of inert gas protection, the Ti 2 AlNb alloy rod made into spherical powder;

[0020] 2) Put Ti 2 AlNb spherical powder is put into the bag and vibrated, and then hot isostatic pressing is performed after degassing;

[0021] 3) For hot isostatic pressing of Ti 2 AlNb powder alloy is subjected to solid solution + two-stage aging heat treatment. The solid solution process is 980°C / 1h / OC, the first-stage aging process is 900°C / 8h / FC, and the second-stage aging is performed directly after the furnace is cooled to 830°C. The process is 830℃ / 16h / FC.

[0022] Ti produced by this method 2 AlNb powder alloys have excellent comprehensive mechanical properties at room temperature and high temperature, excellent long-lasting life, and stable performance in high temperature environmen...

Embodiment 2

[0025] A high performance Ti 2 The heat treatment process of AlNb powder alloy comprises the following steps:

[0026] 1) Using the plasma rotating electrode powder making equipment, under the condition of inert gas protection, the Ti 2 AlNb alloy rod made into spherical powder;

[0027] 2) Put Ti 2 AlNb spherical powder is put into the bag and vibrated, and then hot isostatic pressing is performed after degassing;

[0028] 3) For hot isostatic pressing of Ti 2 AlNb powder alloy is subjected to solid solution + two-stage aging heat treatment. The solid solution process is 1020°C / 2h / AC, the first-stage aging process is 880°C / 6h / FC, and the second-stage aging is directly carried out after the furnace is cooled to 800°C. The process is 800℃ / 20h / FC;

[0029] Ti produced by this method 2 AlNb powder alloys have excellent comprehensive mechanical properties at room temperature and high temperature, excellent long-lasting life, and stable performance in high temperature environ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com