High-voltage and wide-temperature amplitude polymer lithium battery for 3C digital camera and fabrication method of polymer lithium battery

A high-voltage, polymer technology, applied in the direction of non-aqueous electrolyte battery electrodes, circuits, electrical components, etc., can solve problems such as low cost, large-scale continuous production, affecting battery life, battery expansion and deformation, etc., to achieve Improve high-current charge and discharge performance, improve safety performance and operating temperature range, and reduce the effect of lattice constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation method of high-voltage, wide-temperature polymer lithium-ion battery for 3C digital:

[0036] Manufacturing method of the positive electrode:

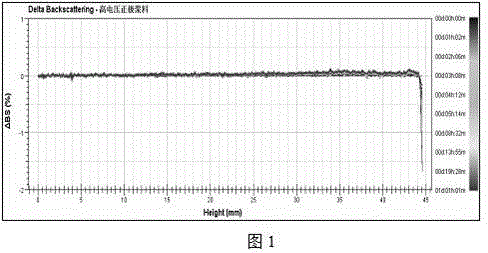

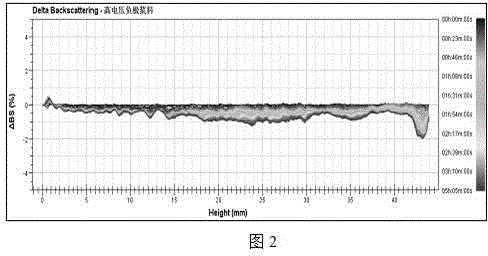

[0037] Positive electrode active material cobalt lithium oxide LiCoO 2, conductive material SuperP, CNT, binder PVDF-5130 and solvent in a formula ratio of 97:1:1:1:30 by weight. Stir the binder PVDF-5130 and the solvent NMP at high speed for 5 hours, then mix the stirred binder solution (50% by mass), the entire mass of the conductive material and 50% by mass of the solvent, and then add the positive active material , after high-speed stirring, add the remaining binder and solvent, and finally stir again at high speed. After adjusting the viscosity, measure the stability of the slurry with a Turbiscan analyzer, coat the prepared slurry evenly on both sides of the aluminum foil, and dry , rolling, and slitting to make a positive electrode sheet with tabs of a specific size.

[0038] Manufacturing method of negativ...

Embodiment 2

[0044] Preparation method of high-voltage, wide-temperature polymer lithium-ion battery for 3C digital:

[0045] Manufacturing method of the positive electrode:

[0046] Positive electrode active material cobalt lithium oxide LiCoO 2 , Conductive material SuperP, KS6, binder PVDF-5130 and solvent in a formula ratio of 96.5:1:1:1.5:29 by weight. Stir the binder PVDF-5130 and the solvent NMP at high speed for 4 hours, then mix the stirred binder solution (half the mass) with the entire mass of the conductive material, then add the positive active material, after high-speed stirring, add the remaining Finally, stir at high speed again, add solvent to adjust the viscosity, measure the stability of the slurry with a Turbiscan analyzer, and evenly coat the obtained slurry on both sides of the aluminum foil, dry, roll, and slitting. Positive tabs with tabs of a specific size.

[0047] Manufacturing method of negative electrode:

[0048] Mix artificial graphite, conductive graphit...

Embodiment 3

[0053] Preparation method of high-voltage, wide-temperature polymer lithium-ion battery for 3C digital:

[0054] Manufacturing method of the positive electrode:

[0055] Positive electrode active material cobalt lithium oxide LiCoO 2 , conductive material SuperP, binder PVDF-HSV900 and solvent in a formula ratio of 96.5:2:1.5:35 by weight. Stir the binder PVDF and the solvent NMP at high speed for 4 hours, then mix and stir the stirred binder solution (half the mass) and the entire mass of the conductive material, then add the positive active material, after high-speed stirring, add the remaining viscose Finally, stir at high speed again, add solvent to adjust the viscosity, measure the stability of the slurry with a Turbiscan analyzer, and evenly coat the obtained slurry on both sides of the aluminum foil, dry, roll, and slitting to make a specific Size positive tabs with lugs.

[0056] Manufacturing method of negative electrode:

[0057] Mix artificial graphite, conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com