Method for measuring titanium content of iron ore

A determination method and technology of iron ore, which are applied in the measurement of color/spectral properties, material analysis by observing the effect on chemical indicators, and analysis by chemical reaction of materials, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

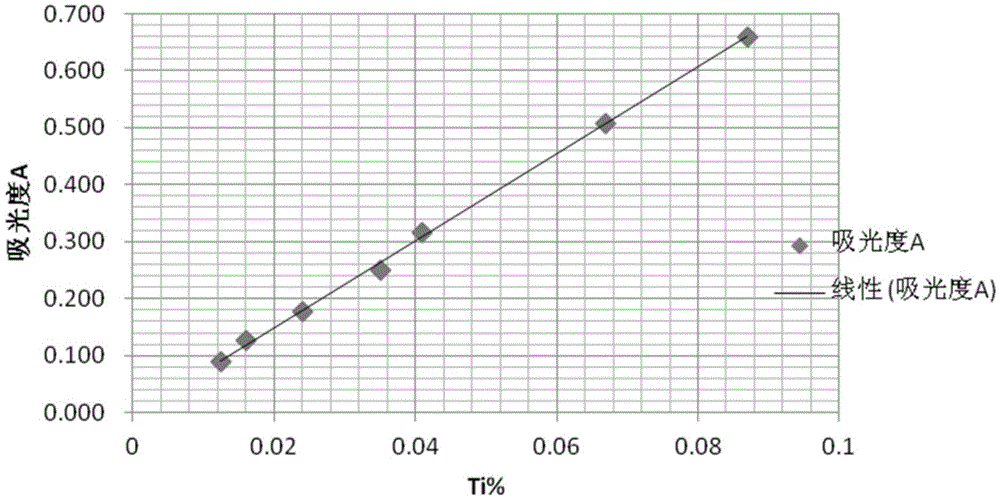

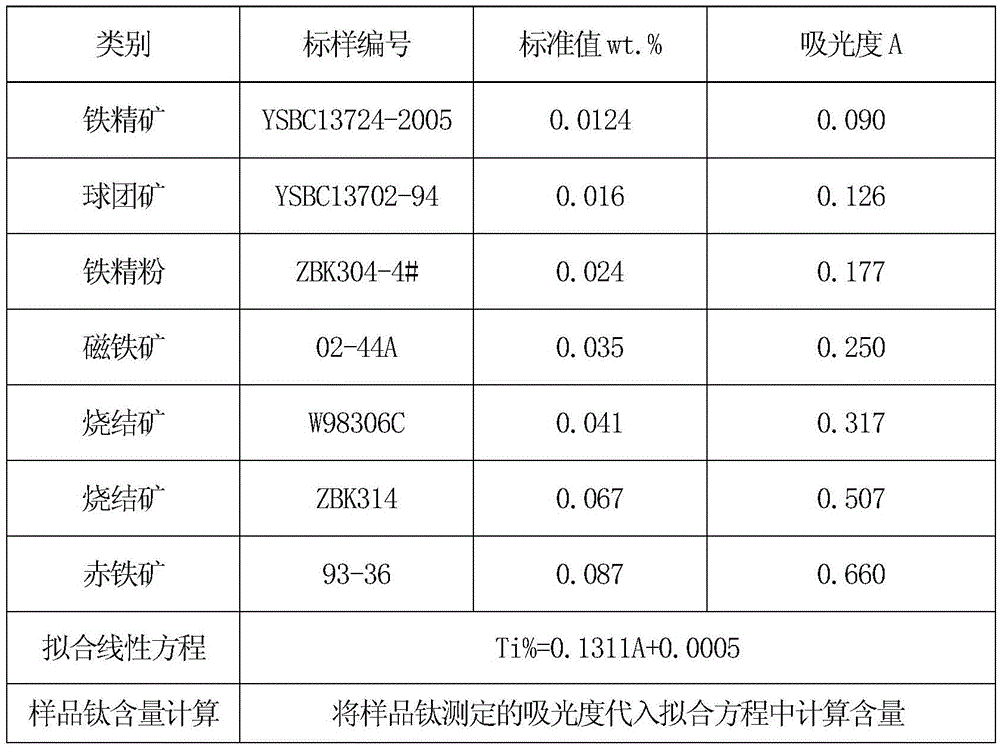

Image

Examples

Embodiment 1

[0028] 1. Reagents and instruments:

[0029] (1) concentrated hydrochloric acid (ρ=1.19g / mL);

[0030] (2) Hydrochloric acid (concentrated hydrochloric acid and water are mixed and prepared at a volume ratio of 1:1);

[0031] (3) Sodium peroxide, solid;

[0032] (4) Ascorbic acid (50g / L), ready-to-use and ready-to-use;

[0033] (5) Diantipyridine methane solution (30g / L): Weigh 30g of diantipyridine methane, dissolve with hydrochloric acid (2mol / L), and dilute to 1000ml, filter and store in a brown bottle.

[0034] (6) Electronic balance with a maximum load of 220g and a sensitivity of 0.1mg;

[0035] (7) Model 721 spectrophotometer;

[0036] (8) Muffle furnace;

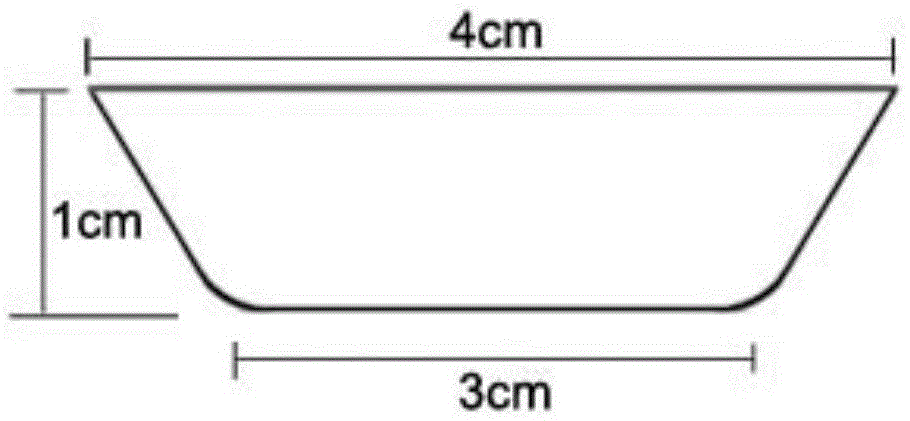

[0037] (9) Iron crucible;

[0038] (10) Iron ore standard samples.

[0039] 2. Samples to be tested

[0040] The particle size of the sample to be tested is required to be less than 150 mesh;

[0041] 3. Test process

[0042] 3.1 Preparation of mother liquor

[0043] Weigh 0.2000g of the sample to be teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com