Alpha-Al2O3 ceramic particles containing lamellar microcrystals as well as preparation method for ceramic particles and application of ceramic particles

A technology of ceramic particles and microcrystals, which is applied in the field of inorganic non-metallic materials, can solve the problems of poor controllability of microcrystalline alumina ceramic particle size, high production cost of ultrafine aluminum hydroxide, cumbersome and lengthy process steps, etc., and achieve crystal shape Good appearance controllability, simple and easy-to-control preparation method, good industrialization prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

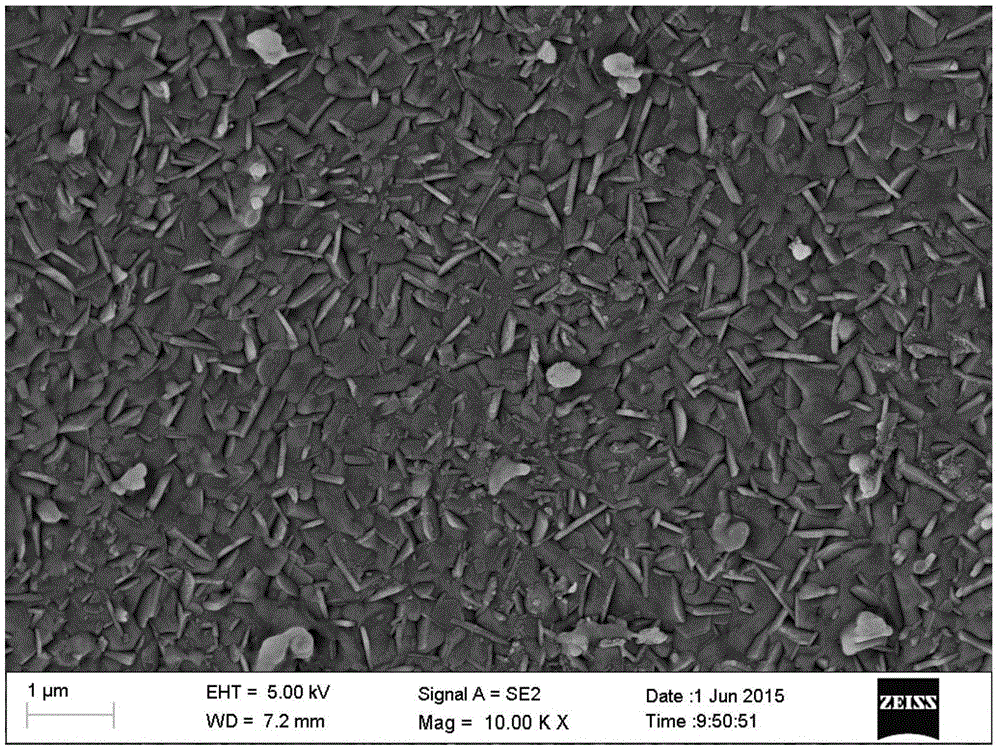

[0037] Example 1, α-A1 containing flaky microcrystals 2 o 3 Preparation of Ceramic Particles

[0038] (1) Add 200.0g of pseudo-boehmite filter cake to 2.0kg of deionized water, stir and disperse to form pseudo-boehmite suspension; mix 8.0g of lanthanum nitrate hexahydrate, 5.0g of magnesium nitrate hexahydrate, 0.1g of hexahydrate Cobalt nitrate and 10.0 g of nitric acid (65 wt %) were added into 200.0 g of deionized water to prepare a solution; the obtained aqueous solution was added to the pseudo-boehmite suspension, mixed and dispersed uniformly to obtain a slurry;

[0039] (2) hydrothermally reacting the slurry obtained in step (1) at 200° C. for 36 hours to obtain a gel;

[0040] (3) Dry the gel obtained in step (2) in an oven at 80°C to obtain dry gel particles, pulverize them with a universal grinder, and sieve to obtain particles with a mesh size of 120 or more. Under vacuum (-0.05MPa) Slowly raise the temperature to 1500°C at a rate of 2.0°C / min, and keep it at the...

Embodiment 2

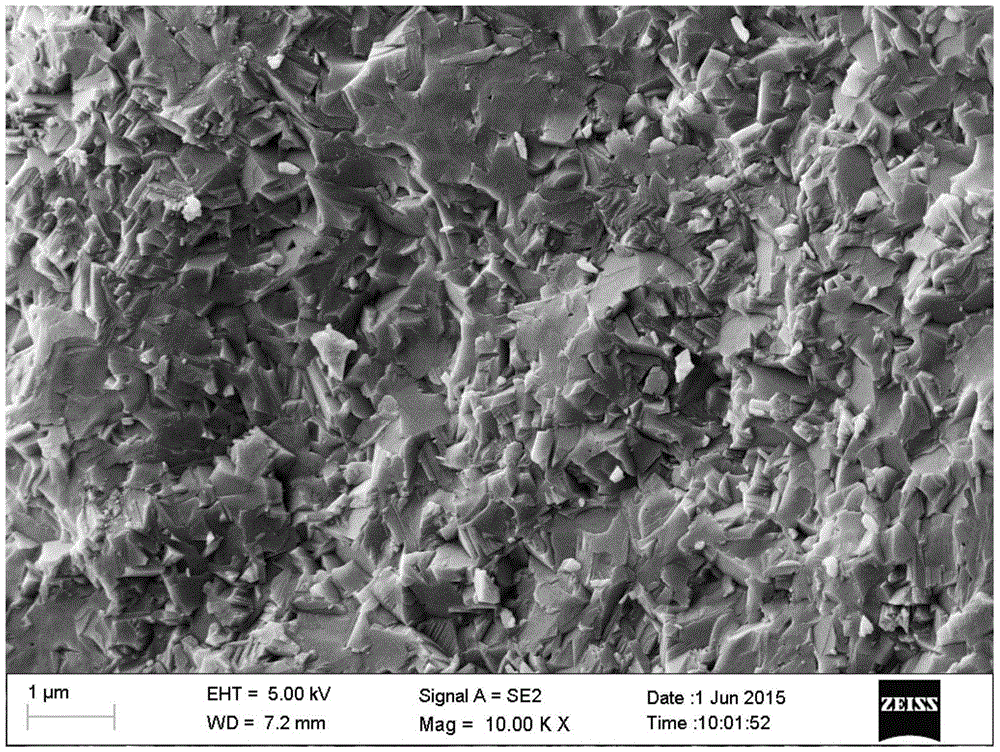

[0042] Example 2, α-A1 containing flaky microcrystals 2 o 3 Preparation of Ceramic Particles

[0043] As described in Example 1, the difference is that in step (3), the gel is dried at 80°C to obtain dry gel particles, pulverized with a universal pulverizer, and sieved to obtain particles with a mesh size of 120 or more. Slowly increase the temperature to 1600°C at a rate of 1 / min, and keep it at the target temperature for 3 hours to obtain α-A1 containing flaky crystallites 2 o 3 ceramic particles.

[0044] The resulting α-A1 2 o 3 The hardness of the microcrystalline ceramic particles is 19.5GPa, and the ball-milling toughness is 75%.

Embodiment 3

[0045] Example 3, α-A1 containing flaky microcrystals 2 o 3 Preparation of Ceramic Particles

[0046] As described in Example 1, the difference is that in step (3), the gel is dried at 80°C to obtain dry gel particles, pulverized with a universal pulverizer, and sieved to obtain particles with a mesh size of 120 or more. Slowly increase the temperature to 1450°C at a rate of 1 / min, and keep it at the target temperature for 3 hours to obtain α-A1 containing flaky crystallites 2 o 3 ceramic particles.

[0047] The resulting α-A1 2 o 3 The hardness of the microcrystalline ceramic particles is 18.5GPa, and the ball-milling toughness is 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com