A high-efficiency and high-quality laser-micro-arc plasma hybrid welding method

A hybrid welding and plasma technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of inability to achieve composite effects, achieve the effects of improving plasma effects, reducing residual stress, and improving effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

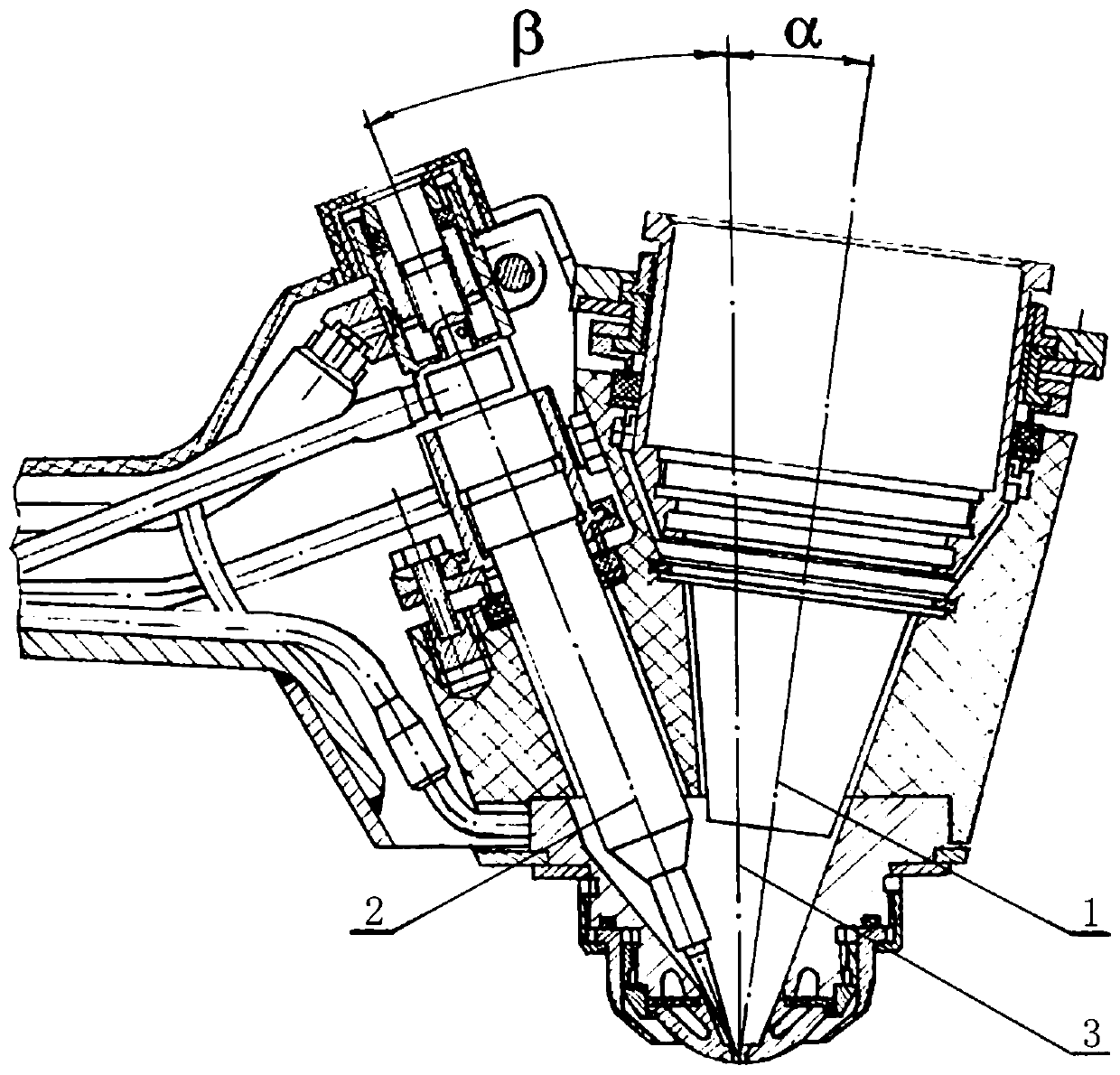

Image

Examples

Embodiment 1

[0033] Comparative test of butt welding of Al alloy (АМг6) plate with thickness δ=1.4mm

[0034] 1) Laser welding: continuous fiber laser beam P=400W, welding speed is 30m / h, penetration depth is 0.1-0.3mm;

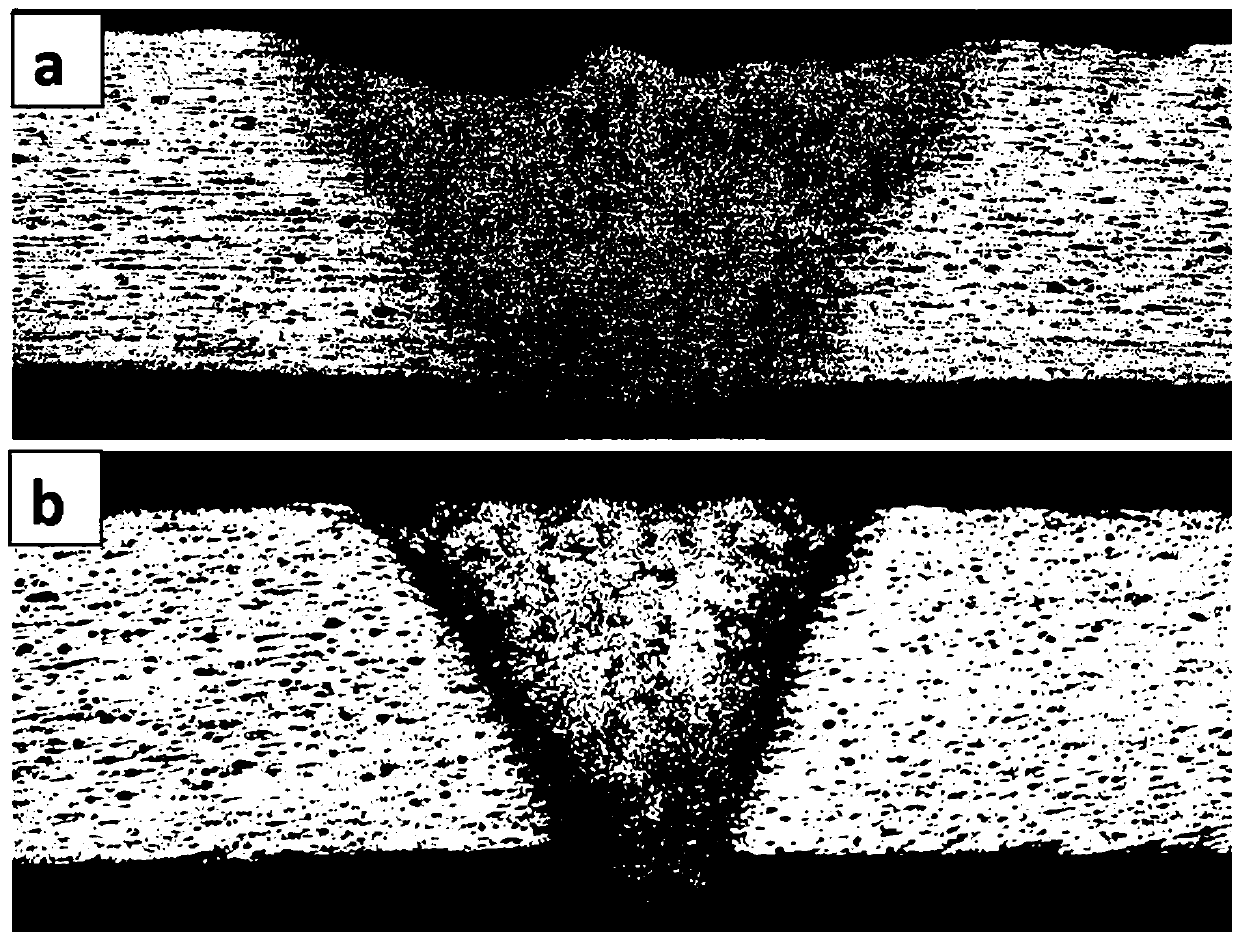

[0035] 2) Micro-arc plasma welding: pulse mode, the positive pulse can melt the metal, while the negative pulse can cathodically clean the oxide film on the aluminum alloy surface. Positive current І 正极 =30 А, reverse current І 反极 =10 А, positive pulse duration τ 正极 =20 ms, antipolar pulse duration τ 反极 =10 ms, the arc voltage U=19 V, the welding speed is 30m / h, the amount of argon used as the plasma generating gas is 3 l / min, and the amount used as the shielding gas is 9 l / min. Welding effects such as figure 2 as shown in a;

[0036] 3) Laser-micro-arc plasma hybrid welding: Combining the above process parameters of laser and micro-arc plasma welding, the welding speed is increased to 150m / h (5 times the original efficiency). Welding effects such as figure 2 Sh...

Embodiment 2

[0039] Comparative test of butt welding of Al alloy (АМг6) plate with thickness δ=1.4mm

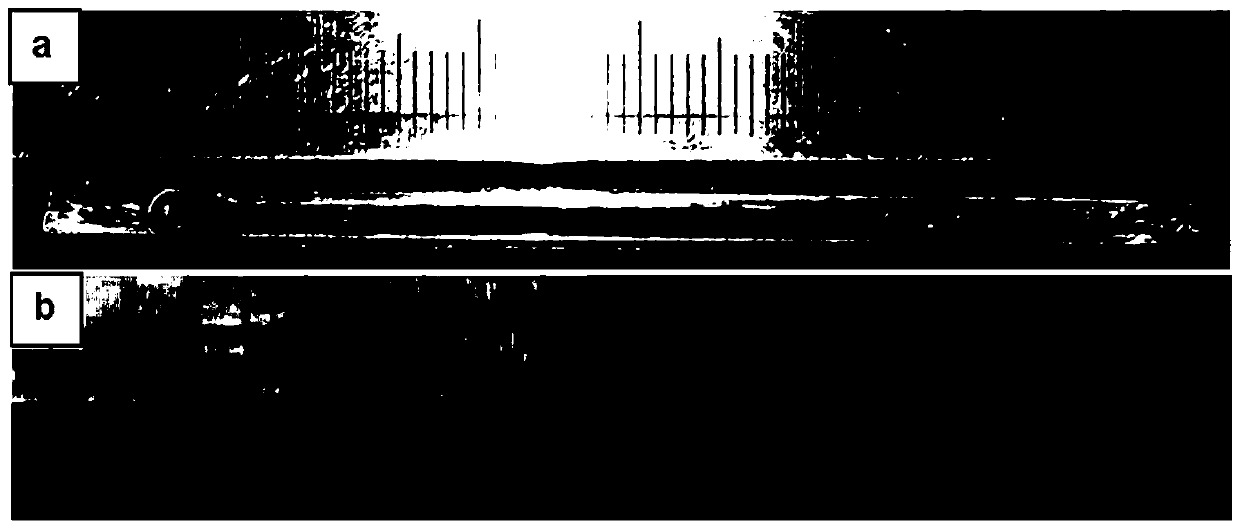

[0040] 1) Laser welding: continuous fiber laser beam P=400W, welding speed is 110m / h. Welding effects such as image 3 as shown in a;

[0041] 2) Laser-micro-arc plasma hybrid welding: pulse mode, positive current І 正极 =12 А, reverse current І 反极 =7А, positive pulse duration τ 正极 =30 ms, antipolar pulse duration τ 反极 =10 ms, arc voltage U=16 V, the amount of argon used as the plasma generating gas is 3 l / min, the amount used as the shielding gas is 9 l / min, the welding speed is 170m / h, P=400W, the focus appears on the surface of the sample . Welding effects such as image 3 Shown in b.

[0042] Comparison of test results: the size of the laser welding seam is small, the speed is too fast, and the forming is not good. The width of the upper surface of the composite welding seam is 1.14mm, the width of the lower surface is 0.39mm, and the width of the heat-affected zone is 0.05mm. ...

Embodiment 3

[0044] Performance test of Al alloy (АМг3 and АМг6) plates with thickness δ=3 mm

[0045] Laser-micro-arc plasma hybrid welding: pulse mode, positive current І 正极 =50-60 А, reverse current І 反极 20-30 А, positive pulse duration τ 正极 =20 ms, antipolar pulse duration τ 反极 =10 ms, arc voltage U=20V, the amount of argon used as plasma generating gas is 3 l / min, the amount of argon used as shielding gas is 9 l / min, the welding speed is 50m / h, P=1000W, the focus appears under the surface of the sample 0.5mm.

[0046] Tensile specimens of the two materials are tested for tensile strength σ according to standard cut samples в . The results show that compared with the base metal, the joint strength of АМг3 alloy exceeds 80% of that of the base metal, while that of АМг6 alloy exceeds 90%.

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com