Positive electrode material for sulfur-based lithium ion battery and preparation method and application of positive electrode material

A positive electrode material and ion battery technology, applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve the problems of poor cycle performance and low specific capacity of lithium-sulfur full batteries, and achieve high energy density, low cost, and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

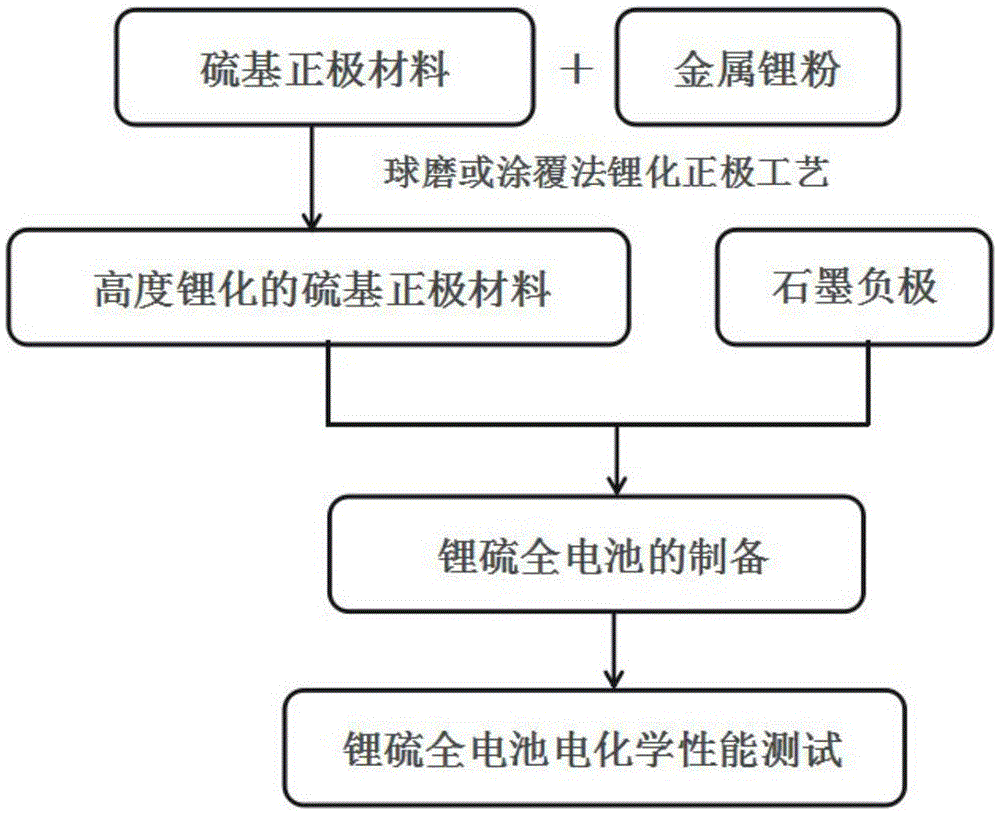

Method used

Image

Examples

Embodiment 1

[0035] (1) Under the protection of argon atmosphere, according to metal lithium powder and sulfur-polyacrylonitrile composite material (the mass ratio of sulfur to polyacrylonitrile is 4:1 (because the sulfur-polyacrylonitrile composite material has been heat-treated, the actual sulfur The content is about 40% to 60%)) and the mass ratio is 1:6. Weigh 100mg of lithium metal powder and 600mg of sulfur-polyacrylonitrile composite material, and according to the ratio of lithium metal powder (mg): electrolyte (ml) = Add 30ml of 1MLiPF dropwise at a ratio of 100:30 6 -EC / DMC (volume ratio 1:1) electrolyte, under the condition of argon atmosphere and electrolyte infiltration, use a planetary ball mill for 3 hours at a speed of 600 rpm; realize the composite of metal lithium powder and sulfur-polyacrylonitrile The materials are evenly mixed, and finally lithiated for 48 hours under the protection of argon at 25°C to obtain a highly lithiated positive electrode material;

[0036] (2)...

Embodiment 2

[0041] (1) The sulfur-based active material (sulfur-polyacrylonitrile composite material (the mass ratio of sulfur to polyacrylonitrile is 4:1 (because the sulfur-polyacrylonitrile composite material has been heat-treated, the actual sulfur content is about 40% to 60%)), the conductive agent SuperP and the binder polyvinylidene fluoride (PVDF) are mixed in a mass ratio of 8:1:1, and the nitrogen methyl pyrrolidone solvent is dropped to form a slurry, which is evenly coated on the surface containing On the carbon aluminum foil current collector, the coating thickness of the slurry is 0.08mm. After drying at 60°C for 6 hours, it is rolled at 5Mpa and cut into positive electrodes;

[0042] (2) Under the protection of an argon atmosphere, according to the mass ratio of the metal lithium powder and the sulfur-polyacrylonitrile composite material in step 1, the ratio of 1:6, the metal lithium powder is evenly coated on the step by using the coating method. On the sulfur-based positi...

Embodiment 3

[0046] Others are the same as Example 1, except that in step 1, the positive electrode active material is a sulfur-polypyrrole composite material (the mass ratio of sulfur to polypyrrole is 2:1 (because the sulfur-polypyrrole composite material has been heat-treated, the actual sulfur The content is about 45% to 65%)); the current collector is nickel foam, and the coating thickness of the slurry is 0.1mm; it is ball milled with a planetary ball mill at a speed of 600 rpm under the condition of argon atmosphere and electrolyte infiltration 1h; realize the uniform mixing of metal lithium powder and sulfur-polypyrrole composite material, and finally obtain a highly lithiated positive electrode material after 12 hours of lithiation time under the condition of argon protection and 25°C.

[0047] The lithium-sulfur full battery prepared in this example was tested for battery charge and discharge cycle performance through the Xinwei BTS-5V5mA channel, and the first discharge specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com