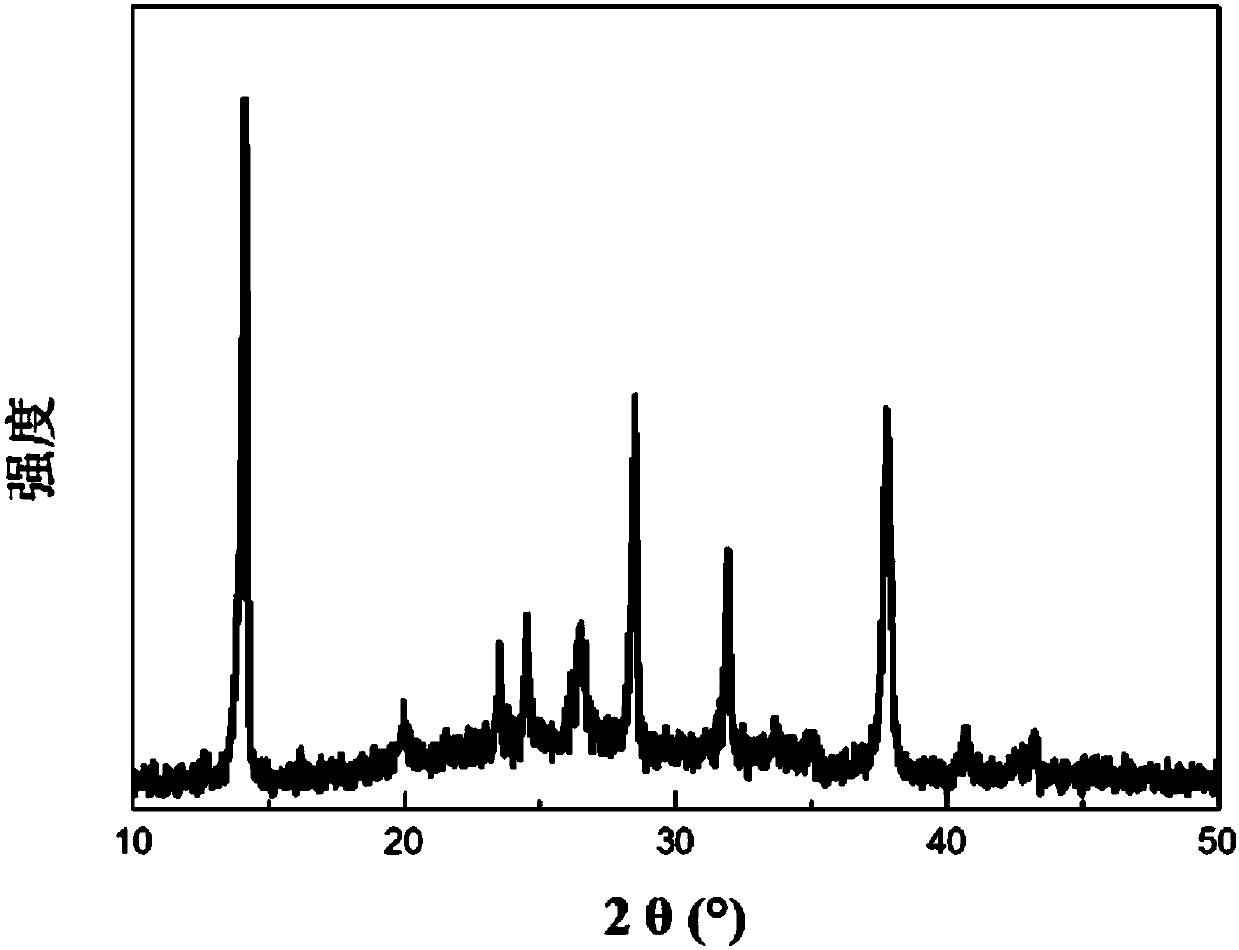

A method for preparing high crystallinity perovskite thin films in air

A high-crystallinity, perovskite technology, applied in electrical components, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems of reducing the crystallinity of perovskite films, poor performance, expensive instruments, etc., to improve reliability Reproducibility, reduce preparation cost, and improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Clean the FTO glass sequentially with glass cleaner, acetone, and ethanol for 20 minutes, and then dry it in an oven;

[0034] Step 2: Dissolve lead iodide in N,N-dimethylformamide solution, heat to 70°C and stir for 6 hours to obtain 1M lead iodide / N,N-dimethylformamide solution;

[0035] Step 3: Dissolve methylamine iodide in isopropanol solution, heat to 70°C, and keep warm for 2 hours to obtain 10 mg / ml methylamine iodide / isopropanol solution;

[0036] Step 4: Spin-coat the lead iodide N,N-dimethylformamide solution prepared in step 2 on the conductive substrate dried in step 1 at 3000 rpm, and anneal at 70°C for 10 minutes to obtain a uniform film with a thickness of 300nm. Lead iodide film;

[0037] Step 5: Place the lead iodide film prepared in step 4 on the heating platform, quickly cover the sample with a petri dish, then drop 50 μL dimethyl sulfoxide on the edge of the petri dish, and treat at 70°C for 10 minutes;

[0038] Step 6: Spin-coat the methy...

Embodiment 2

[0040] Step 1: Clean the FTO glass sequentially with glass cleaner, acetone, and ethanol for 20 minutes, and then dry it in an oven;

[0041] Step 2: Dissolve lead bromide in N,N-dimethylformamide solution, heat to 70°C and stir for 6 hours to obtain 1mol / L lead bromide / N,N-dimethylformamide solution;

[0042] Step 3: Dissolve methylamine bromide in isopropanol solution, heat to 70°C, and keep warm for 2 hours to obtain 10mg / ml methylamine bromide / isopropanol solution;

[0043] Step 4: Spin-coat the lead bromide N,N-dimethylformamide solution prepared in step 2 on the conductive substrate dried in step 1 at 3000 rpm, and anneal at 70°C for 10 minutes to obtain a uniform film with a thickness of 300nm. Lead bromide film;

[0044] Step 5: Place the lead bromide film prepared in step 4 on the heating platform, quickly cover the sample with a petri dish, then drop 50 μL dimethyl sulfoxide on the edge of the petri dish, and treat at 70°C for 10 minutes;

[0045] Step 6: Spin-coat...

Embodiment 3

[0047] Step 1: Clean the FTO glass sequentially with glass cleaner, acetone, and ethanol for 20 minutes, and then dry it in an oven;

[0048] Step 2: Dissolve lead iodide in N,N-dimethylformamide solution, heat to 70°C and stir for 6 hours to obtain 1mol / L lead iodide / N,N-dimethylformamide solution;

[0049] Step 3: Dissolve methylamine iodide in isopropanol solution, heat to 80°C, and keep warm for 1 hour to obtain 10 mg / ml methylamine iodide / isopropanol solution;

[0050] Step 4: Spin-coat the lead iodide N,N-dimethylformamide solution prepared in step 1 on the conductive substrate dried in step 1 at 2000 rpm, and anneal at 80°C for 10 minutes to obtain a uniform film with a thickness of 500nm. Lead iodide film;

[0051] Step 5: Place the lead iodide film prepared in step 4 on the heating platform, quickly cover the sample with a petri dish, then drop 50 μl dimethyl sulfoxide on the edge of the petri dish, and treat at 70°C for 20 minutes;

[0052] Step 6: spin-coat the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com