LED optical engine encapsulation structure

A packaging structure, LED light source technology, applied to the circuit layout on the support structure, modification through conduction and heat transfer, electrical components, etc., can solve the problems of high cost, large volume of semiconductor devices, low integration, etc., and achieve production efficiency Improvement, small size, and improved integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

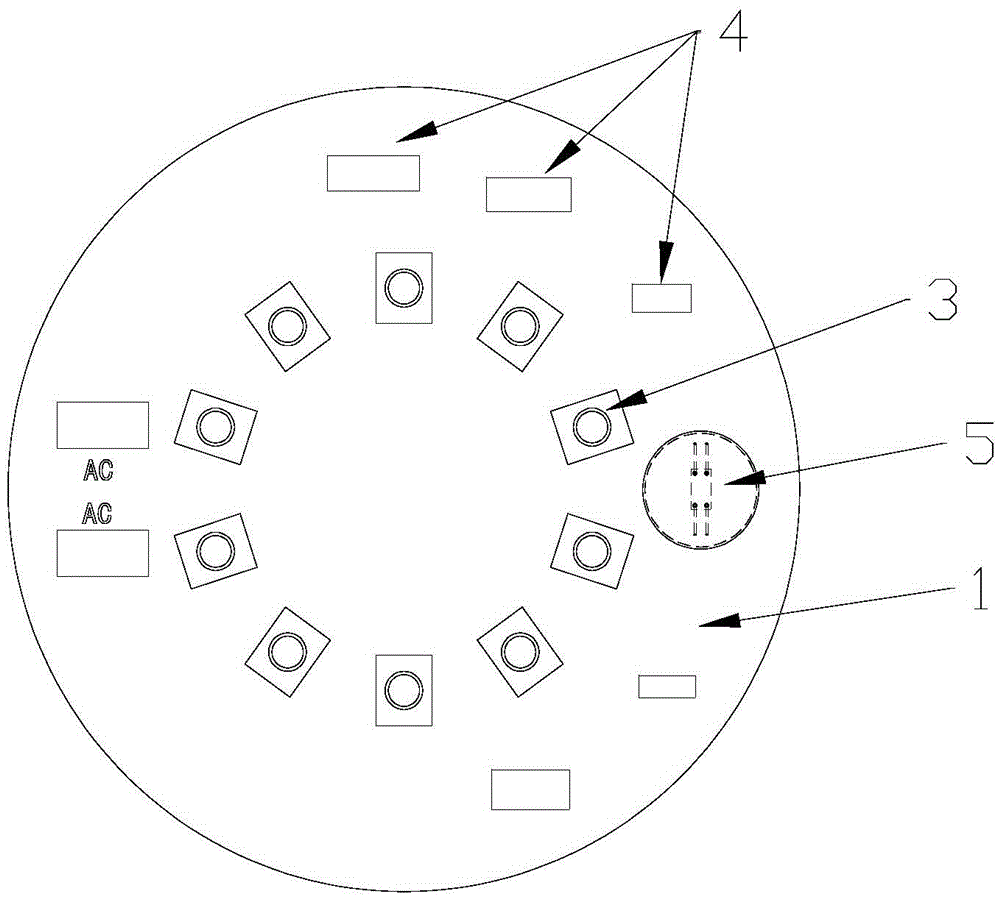

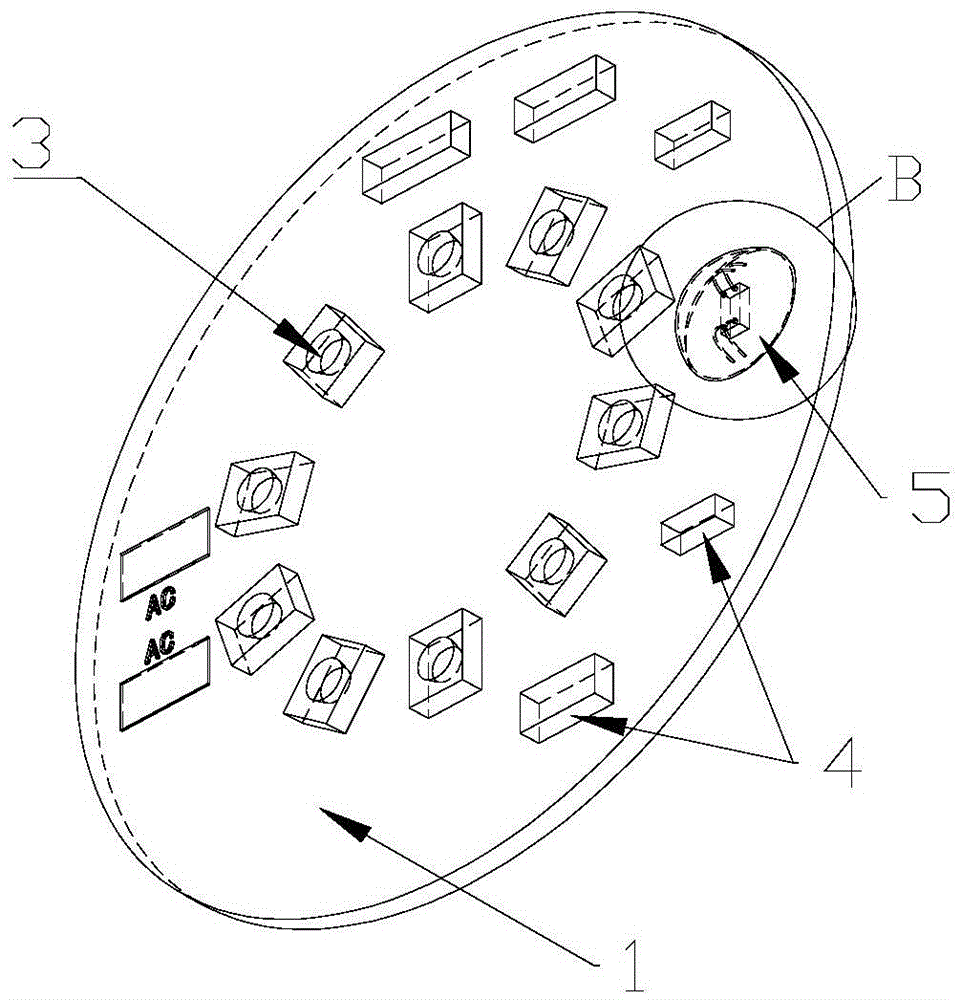

[0064] Example 1 ( figure 1 , 2 、3)

[0065] For the light engine made of SMD, EMC, CSP, Wicop patch type LED light source patch, semiconductor chip packaging can be carried out first, and then the LED light source patch can be mounted. The specific process is as follows:

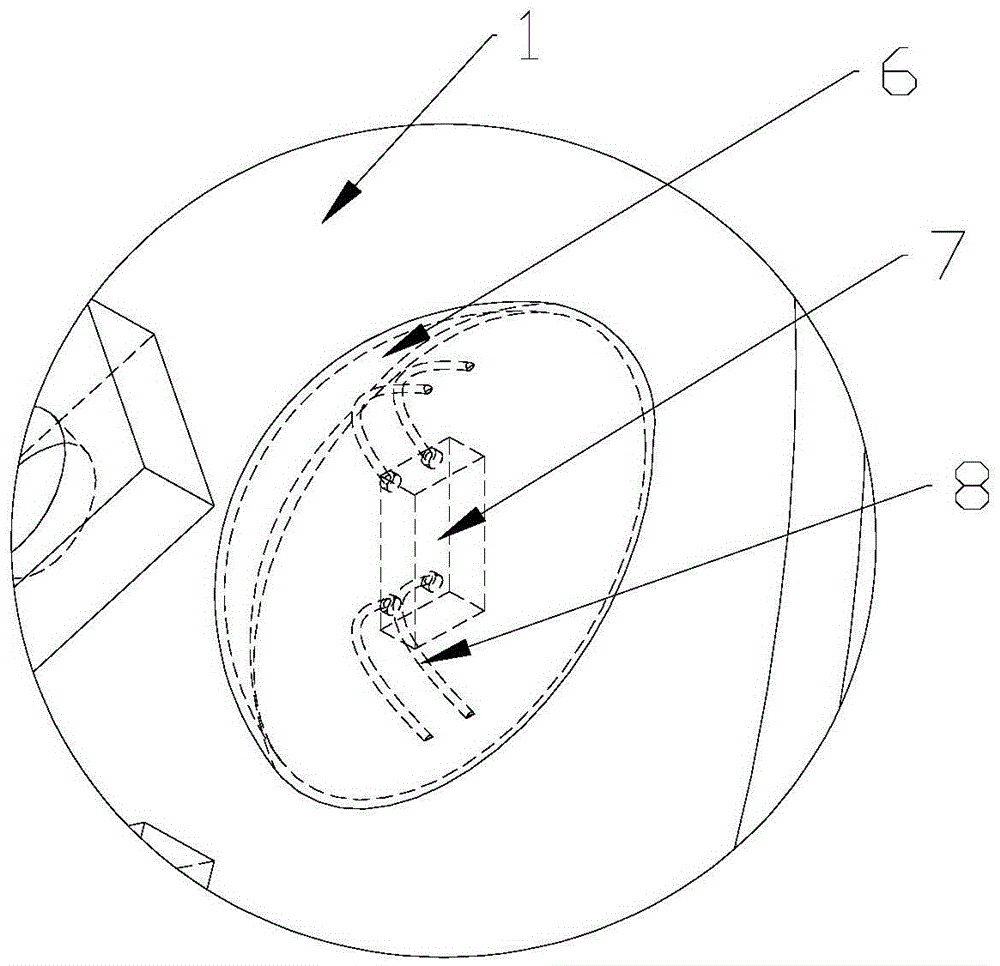

[0066] Die bonding uses die bonding glue to fix the semiconductor wafer 7 on the die bonding position of the application substrate 1 . The die-bonding glue here can be selected according to the heat dissipation and shear force requirements of the semiconductor chip, and can be silver glue, epoxy-based insulating glue, silicon-based insulating glue, etc.

[0067] The wire bonding connects the semiconductor chip 7 and the circuit channel of the application substrate 1 through the guide wire 8 to the semi-finished product after the crystal bonding. The guide wire can be gold wire, alloy wire, copper wire, aluminum wire.

[0068] The sealant uses an adhesive material 6 to seal and protect the semiconductor...

Embodiment 2

[0071] Example 2 ( Figure 4 , 5 、6)

[0072] For the light engine manufactured by the COB type LED light source chip and the LED light source chip is a front-mount chip, the packaging of the semiconductor chip and the packaging of the LED light source chip can be performed simultaneously. The specific process is as follows:

[0073] Die-bonding uses die-bonding glue to fix the semiconductor wafer 7 and the wafer of the COB type LED light source 2 on the die-bonding position of the application substrate 1 . The die-bonding glue here can be selected according to the heat dissipation and shear force requirements of the semiconductor chip, and can be silver glue, epoxy-based insulating glue, silicon-based insulating glue, etc.

[0074] The wire bonding connects the semiconductor chip 7 , the chip of the COB LED light source 2 and the circuit channel of the application substrate 1 through the guide wire 8 to the semi-finished product after the crystal bonding. The guide wire c...

Embodiment 3

[0078] Embodiment 3 ( Figure 4 , 5 、6)

[0079] For a light engine made of a COB type LED light source chip and the LED light source chip is a flip chip, the packaging of the semiconductor chip and the packaging of the LED light source chip can be performed simultaneously. The specific process is as follows:

[0080] Die-bonding 1 uses a conductive material to connect and fix the chip electrode of the COB LED light source 2 with the circuit on the application substrate 1 . The conductive material can be silver glue, solder paste, AuSn alloy and other eutectic solders.

[0081] Die-bonding 2 uses die-bonding glue to fix the semiconductor wafer 7 on the die-bonding position of the application substrate 1 . The die-bonding glue here can be selected according to the heat dissipation and shear force requirements of the semiconductor chip, and can be silver glue, epoxy-based insulating glue, silicon-based insulating glue, etc.

[0082] The semi-finished product after the die b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com