Metal coating with high bonding strength and high cohesion strength, as well as thermal spraying method and application of metal coating

A technology of bonding strength and cohesive strength, applied in metal material coating process, metal processing equipment, coating and other directions, can solve the problems of inability to achieve particle temperature self-bonding effect and weak bonding, and achieve overall structural stability and thermal stability. Enthalpy increase, the effect of increasing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

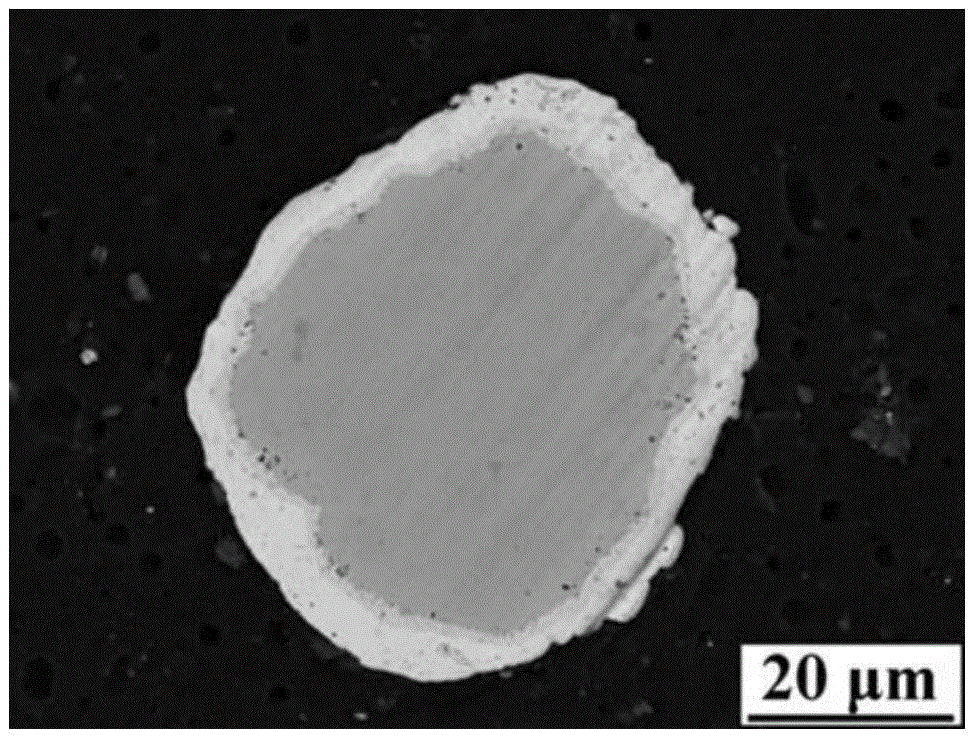

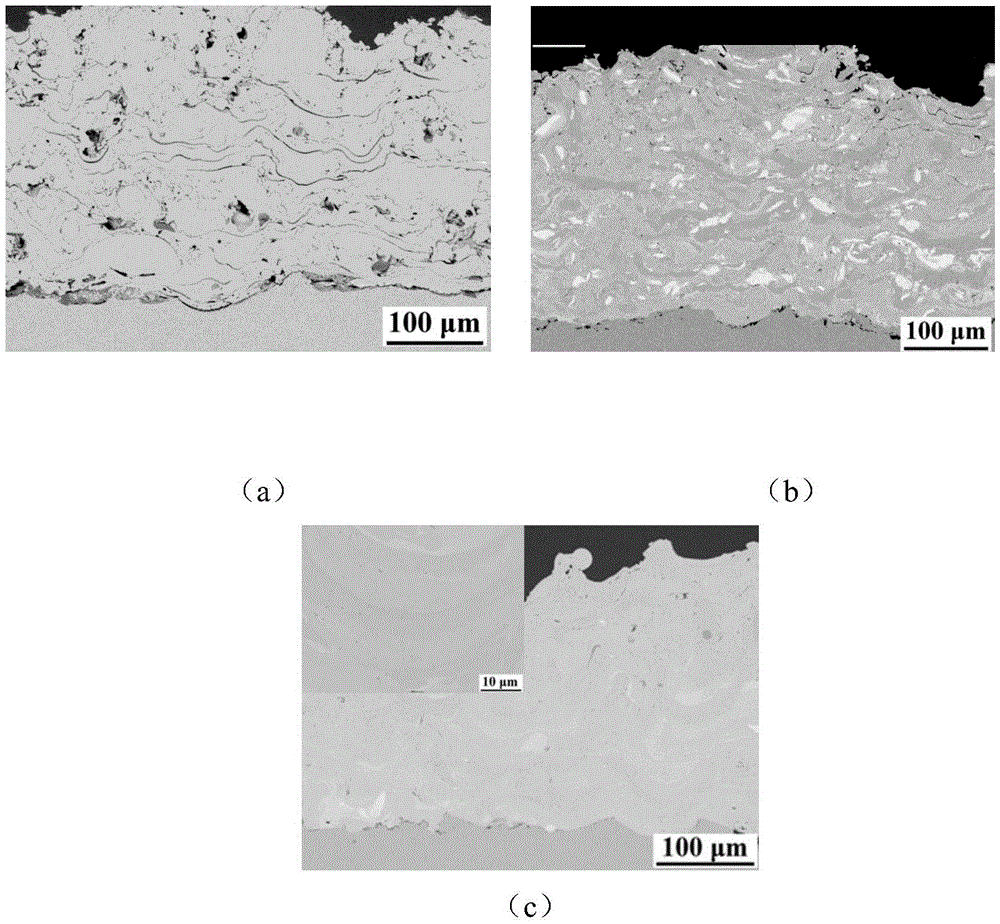

[0030] Mo-coated Ni20Cr shell-core composite structure powder particle cross-section such as figure 1 shown. as figure 1 The shown Mo coated spherical Ni20Cr powder with a particle size between 75-100 μm is used as a plasma spray powder. , Prepared after 30min protective atmosphere heat treatment. Then deposit a coating on the surface of the stainless steel substrate under the plasma arc power of 30-38kW, and the cross-sectional structure of the coating is as follows figure 2 As shown in (c), figure 2 (a) For comparison, the cross-section structure of the pure Ni-20Cr alloy coating prepared under the same plasma spraying conditions, figure 2 (b) As a comparison, the cross-sectional structure of Mo simple mechanical coating NiCr alloy coating prepared under the same conditions. and figure 2 (a) with figure 2 The conventional plasma spraying Ni20Cr coating shown in (b) is compared with the coating prepared by Mo mechanically coating NiCr powder, the density of the Ni...

Embodiment 2

[0033] Mo coated Ni60 powder with a particle size of 75-150 μm was used, and after being treated at 700 ° C for 6 hours, a composite structure powder was obtained; the composite structure powder was deposited on the surface of a low-carbon steel substrate at a plasma arc power of 35 kW, and the coating thickness of about 400 μm was obtained. The tensile strength of the coating was tested according to the ASTMC633 standard. The results showed that all the samples were broken at the adhesive layer, and the average strength was 72MPa, indicating that the bonding strength and cohesive strength of the coating were both greater than 72MPa.

Embodiment 3

[0035] Use Ni-coated Zn powder with a particle size of 45-110 μm and a mass ratio of 15 / 85, and treat it at 900 ° C for 4 hours to obtain a composite structure powder; the composite structure powder is flame sprayed on the surface of the Mg alloy substrate to prepare a thickness of ~ 250 μm The Ni-Zn alloy coating was tested according to the ASTMC633 standard to test the tensile strength of the coating. The results showed that all samples were broken at the adhesive layer, and the average strength was 68MPa, indicating that the bonding strength and cohesive strength of the coating were both greater than 68MPa.

[0036] In summary, the method of the present invention aims at the problem that it is difficult or impossible to realize the metallurgical self-bonding reaction in the collision deposition process of molten particles and obtain a sufficiently dense coating with good inter-particle bonding by using the existing sprayed metal alloy powder materials. A method of coating po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com