Manufacturing method of ultra-purity industrial pure iron

An industrial pure iron and manufacturing method technology, applied in the field of metal smelting, can solve the problems of inability to manufacture steel types, high price, complicated process methods, etc., and achieve the effect of improving fracture toughness and low sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

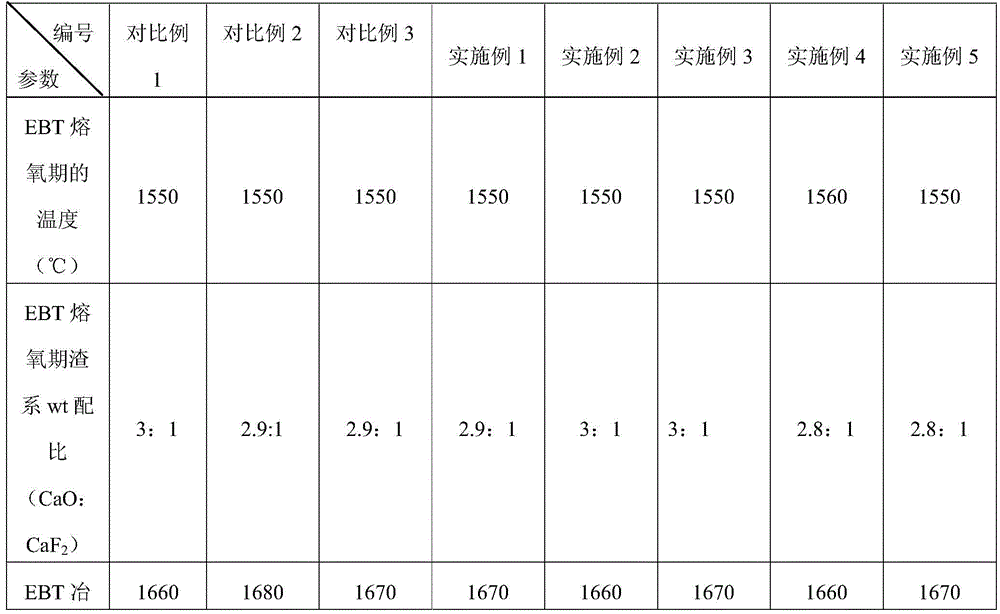

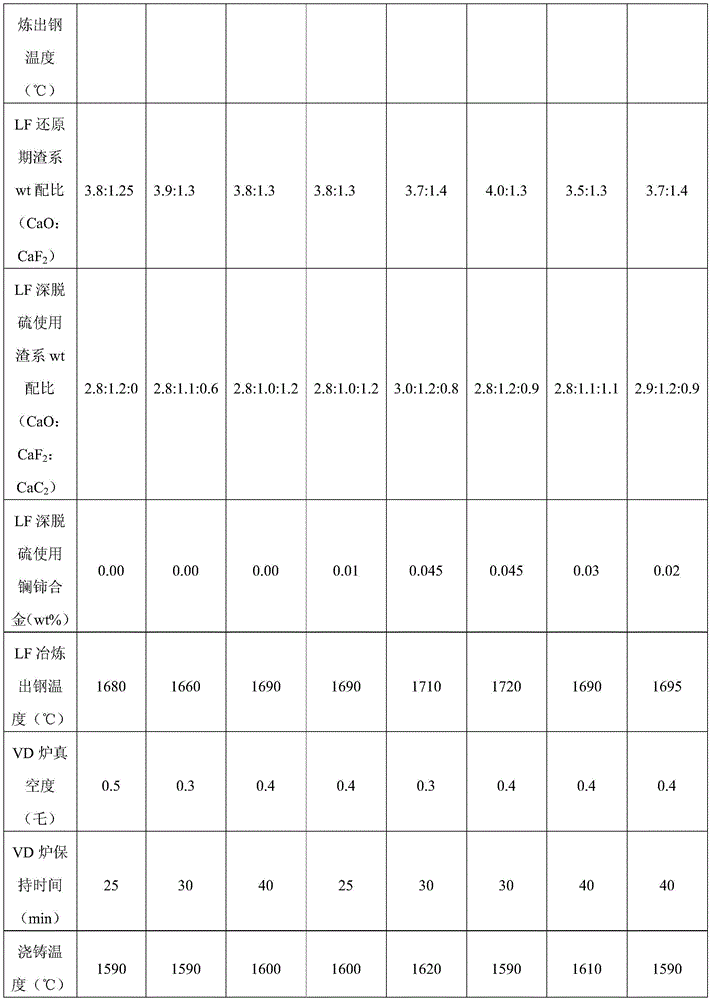

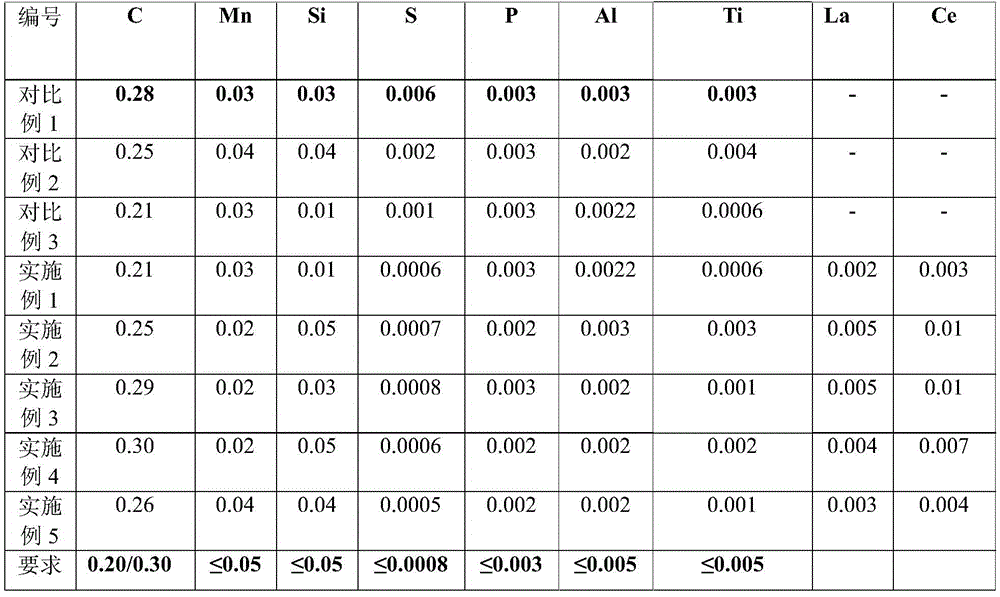

[0049] The following steps are used to produce ultra-purity industrial pure iron (see Table 1 for specific process parameters, Table 2 for the components of pure iron, and Table 3 for the influence of lanthanum and cerium on Aermet100 steel K1c):

[0050] Ingredients requirements: scrap steel is composed of S≤0.02%P≤0.020% high-quality scrap steel and electrode blocks. Control of chemical composition of ingredients: C0.7~1.0%, P≤0.020%, S≤0.02%, white ash requirement: CaO content ≥95%, fluorite requirement: CaF2 content ≥97%, CaC 2 The content is ≥97%.

[0051] (1) The blast furnace hot metal is smelted by the EBT oxidation method: the slag system used is CaO+CaF 2 , Red delivery blast furnace molten iron, the composition of molten iron requires P, S≤0.02%;

[0052] In the oxygen melting period of EBT smelting: the slag system ratio in the oxygen melting period is CaO:CaF 2 =(2.8~3.0):1; control the temperature at 1550~1560℃, until C≤0.1wt%, P≤0.001wt%, completely remove the slag, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com