Dicyclopentadiene polymer modified asphalt and preparation method thereof

A technology of dicyclopentadiene and modified asphalt, used in building structures, building components, building insulation materials, etc., can solve the problem of durability not meeting industry expectations, increase rigidity, improve road performance, and simplify processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

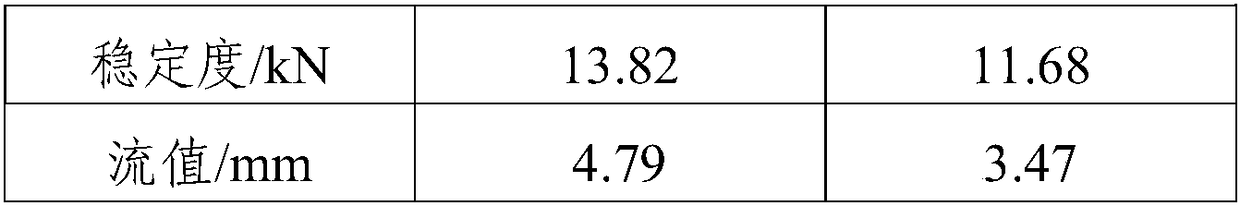

Embodiment 1

[0040] This embodiment provides a dicyclopentadiene and / or dicyclopentadiene derivative polymer modified asphalt and a preparation method thereof, the steps are as follows:

[0041] First put 100 parts of petroleum asphalt into 135°C for drying, put it into a heating mantle and cool it to 110°C, then start stirring; prepare 20 parts of kerosene, and slowly add it to the petroleum asphalt; stir until it is uniform, then place In the state of normal temperature, let it cool down, and component A can be obtained.

[0042] Put dicyclopentadiene and / or dicyclopentadiene derivatives into 30-40°C for heating and heat preservation to dissolve, take 75 parts of dicyclopentadiene and / or dicyclopentadiene derivatives, add 20.99 parts of kerosene, and wait until fully stirred , add 1 part of triphenylphosphine and stir slightly, then add 0.01 part of grubbs2 generation catalyst, and stir evenly at room temperature to obtain component B.

[0043] Then get 92 parts of component A and 100 p...

Embodiment 2

[0045] This embodiment provides a dicyclopentadiene and / or dicyclopentadiene derivative polymer modified asphalt and a preparation method thereof, the steps are as follows:

[0046] First put 100 parts of petroleum asphalt into 135°C for drying, put it in a heating mantle and cool it to 110°C, then start stirring; prepare 20 parts of gasoline, and slowly add it to the base asphalt; stir until it is uniform, then place In the state of normal temperature, let it cool down, and component A can be obtained.

[0047] Put dicyclopentadiene and / or dicyclopentadiene derivatives into 30-40°C to heat and heat-preserve to dissolve, take 90 parts of dicyclopentadiene and / or dicyclopentadiene derivatives, add 8.99 parts of kerosene, and wait until fully stirred , add 4 parts of triphenylphosphine and stir slightly, then add 0.01 part of grubbs2 generation catalyst, and stir evenly at room temperature to obtain component B.

[0048] Then take 126 parts of component A and 60 parts of compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com