Polypropylene composite cable material and preparation method thereof

A composite cable material and polypropylene technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor mechanical properties of the reinforcement effect, and achieve benefits for popularization and application, good economic value, and improved mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

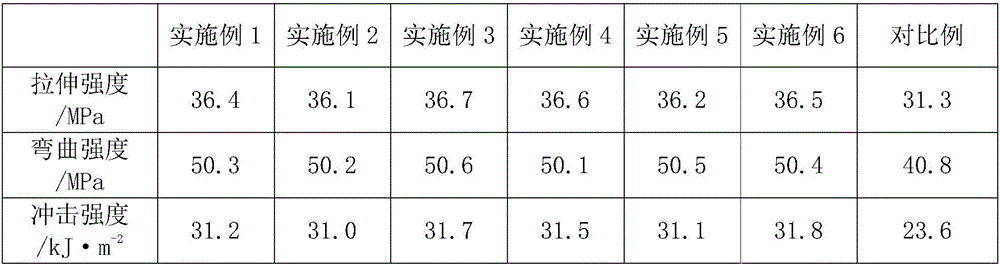

Examples

Embodiment 1

[0027] Polypropylene composite cable material, which is made of the following raw materials in parts by weight: 100 parts of isotactic polypropylene resin, 0.9 part of talcum powder, 0.5 part of antioxidant 168, 1.4 parts of polyethylene wax, 3.8 parts of POE, ammonium polyphosphate 10 parts, 10 parts of maleic anhydride grafted polypropylene, 0.7 parts of UV-531, 18 parts of modified clay.

[0028] Its preparation method comprises the following steps:

[0029] (1) Crush the kale seeds to 80 mesh with a pulverizer to obtain kale seed powder, add the kale seed powder to ether at a solid-to-liquid ratio of 1:8g / mL, put it into an ultrasonic cleaner and extract it at 60°C for 25 The extract is obtained in minutes, the extract is filtered to obtain a filter residue, and the filter residue is dried in an oven at 60°C to obtain kale seed oil;

[0030] (2) Add the kale oil obtained in step (1) to 2 times the weight of distilled water, stir at 80°C for 2 hours to obtain an aqueous so...

Embodiment 2

[0034] Polypropylene composite cable material, which is made of the following raw materials in parts by weight: 100 parts of isotactic polypropylene resin, 0.7 part of talcum powder, 0.7 part of antioxidant 168, 1 part of polyethylene wax, 4 parts of POE, ammonium polyphosphate 12 parts, 8 parts of maleic anhydride grafted polypropylene, 0.9 parts of UV-531, 16 parts of modified clay.

[0035] Its preparation method is with embodiment 1.

Embodiment 3

[0037] Polypropylene composite cable material, which is made of the following raw materials in parts by weight: 100 parts of isotactic polypropylene resin, 0.5 part of talcum powder, 0.9 part of antioxidant 168, 1.5 parts of polyethylene wax, 3.4 parts of POE, ammonium polyphosphate 14 parts, maleic anhydride grafted polypropylene 6 parts, UV-531 1.1 parts, modified clay 14 parts.

[0038] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com