Mannose oligomer oat vinegar and preparation method thereof

A technology of oligomannose and mannose enzymatic hydrolysate is applied in the preparation of vinegar, biochemical equipment and methods, microorganism-based methods, etc., and can solve the problems of single nutrient composition, need to improve nutrition and flavor, and general taste. , to achieve the effect of improving nutritional content, better taste and color, and low procurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

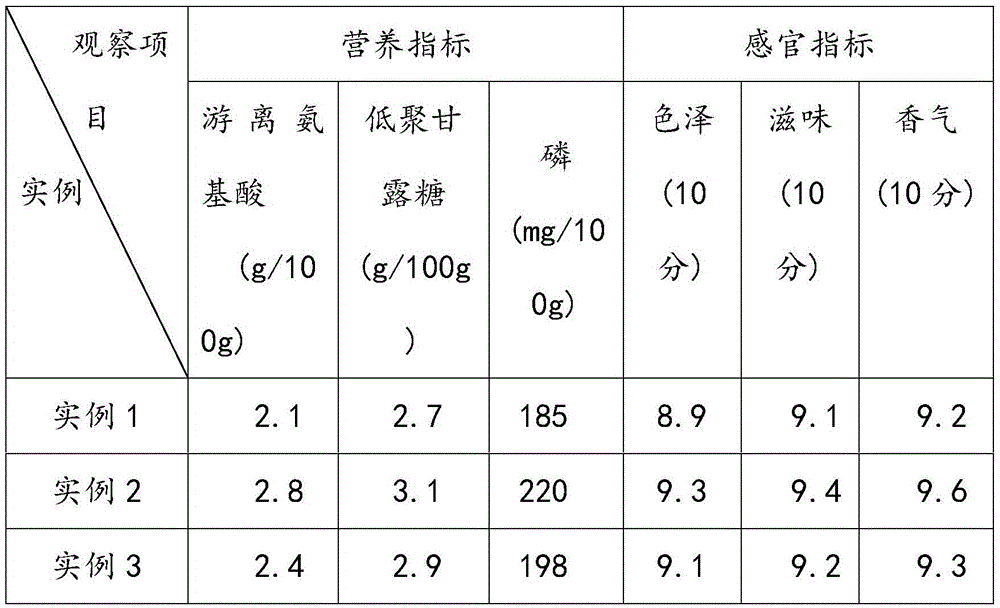

Embodiment 1

[0032] (1) Obtainment of Aspergillus usamii enzyme solution: use potato agar medium (200g potato, 20g glucose, 15g agar, 1L tap water, natural pH) to activate Aspergillus usami (China Industrial Microbial Culture Collection and Management Center, preservation number CICC2145), 28 Cultured at ℃ for 2 days; 1kg of bran, 0.8kg of water, wetting for 0.5h, sterilization at 121°C for 30min, adding 0.2kg of water to mix, and cooling to 28°C to prepare a bran-containing medium, and inoculate activated Aspergillus usami. The inoculation amount is 6% (volume percentage). After culturing at 28°C for 48 hours, the Aspergillus usamii bran koji was obtained; at the same ratio, the ventilated koji method was used to expand the culture to prepare the production Aspergillus usamii bran koji. Take 1 kg of Aspergillus usamii bran koji, add 7 kg of water, stir for 10 minutes, and filter to obtain 7 kg of Aspergillus usamii enzyme solution;

[0033] (2) Preparation of oligomannose enzymatic hydrolys...

Embodiment 2

[0039] (1) Obtainment of Aspergillus usamii enzyme solution: use potato dextrose agar medium to activate Aspergillus usamii, culture at 30°C for 3 days; 2kg bran, add 1.5kg water, moisten for 0.8h, sterilize at 121°C for 30min, add 0.5kg water and mix well Obtain the bran-containing medium, inoculate 10% (volume percentage) of activated Aspergillus usomei when cooled to 30°C, and cultivate it at 30°C for 60 hours to obtain the Aspergillus usamii bran koji; Aspergillus usami has been used for production. Take 2 kg of Aspergillus usamii bran koji, add 14 kg of water, stir for 15 minutes, and filter to obtain 14 kg of Aspergillus usamii enzyme solution;

[0040] (2) Preparation of oligomannose enzymatic hydrolysate: Take 4kg of konjac fly powder, 4kg of waste yeast, 4kg of red algae, and 10kg of water, stir and mix with an electric mixer, add 14kg of Aspergillus usami enzyme solution to the mixed slurry, 55℃ Hydrolyze for 10 hours to obtain oligomannose hydrolysate;

[0041] (3) Sac...

Embodiment 3

[0046] (1) Obtainment of Aspergillus usamii enzyme solution: use potato dextrose agar medium to activate Aspergillus usami, cultivated at 29°C for 2.5 days; bran 1.5kg, add water 1.2kg, wet for 0.6h, sterilize at 121°C for 30min, add 0.35kg water The medium containing bran was prepared by mixing, and when it was cooled to 29°C, it was inoculated with 8% (volume percentage) of activated Aspergillus usami. After 54 hours of cultivation at 29°C, the Aspergillus usami was obtained; Expanded cultivation to prepare Aspergillus usamii bran koji for production. Take 1.5 kg of Aspergillus usamii bran koji, add 10 kg of water, stir for 13 min, and filter to obtain 10 kg of Aspergillus usamii enzyme solution;

[0047] (2) Preparation of oligomannose enzymatic hydrolysis solution: Take 3kg of konjac fly powder, 3kg of waste yeast, 3kg of red algae, 8kg of water, stir and mix with an electric mixer, add 10kg of Aspergillus usami enzyme solution to the mixed slurry, 52℃ Hydrolyze for 9h to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com