Acrylamide/sodium acrylate multi-component copolymer, method for preparing same and emulsion water-based fracturing fluid drag reducer

A technology of multi-component copolymer and acrylamide, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that cannot meet the requirements of use, and achieve the effects of easy twisting and rotation, excellent drag reduction performance, and reduced formation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

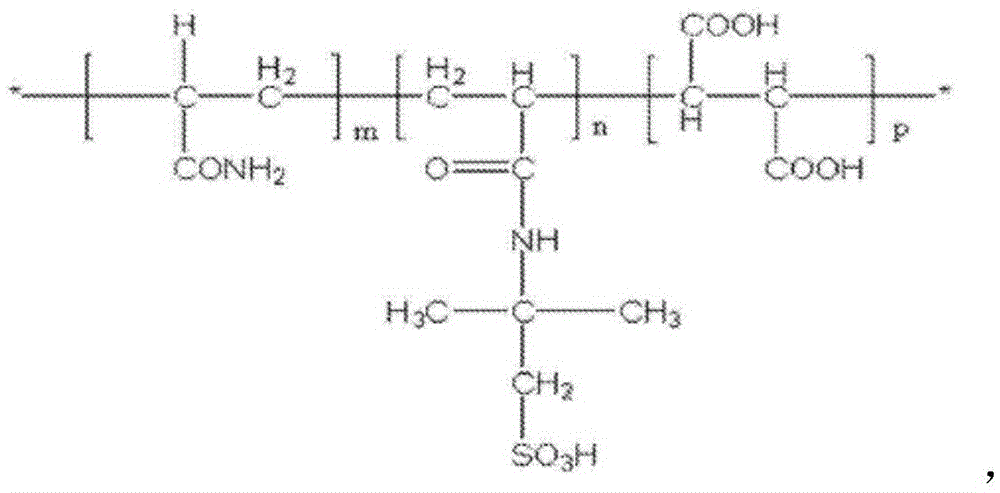

[0052] The preparation method of the acrylamide / sodium acrylate multi-polymer of embodiment comprises the following steps:

[0053] 1) In a jacketed closed reactor, add an organic solvent and an emulsifier, start the agitator for mixing, and pass nitrogen gas for 10 minutes to obtain an oil phase;

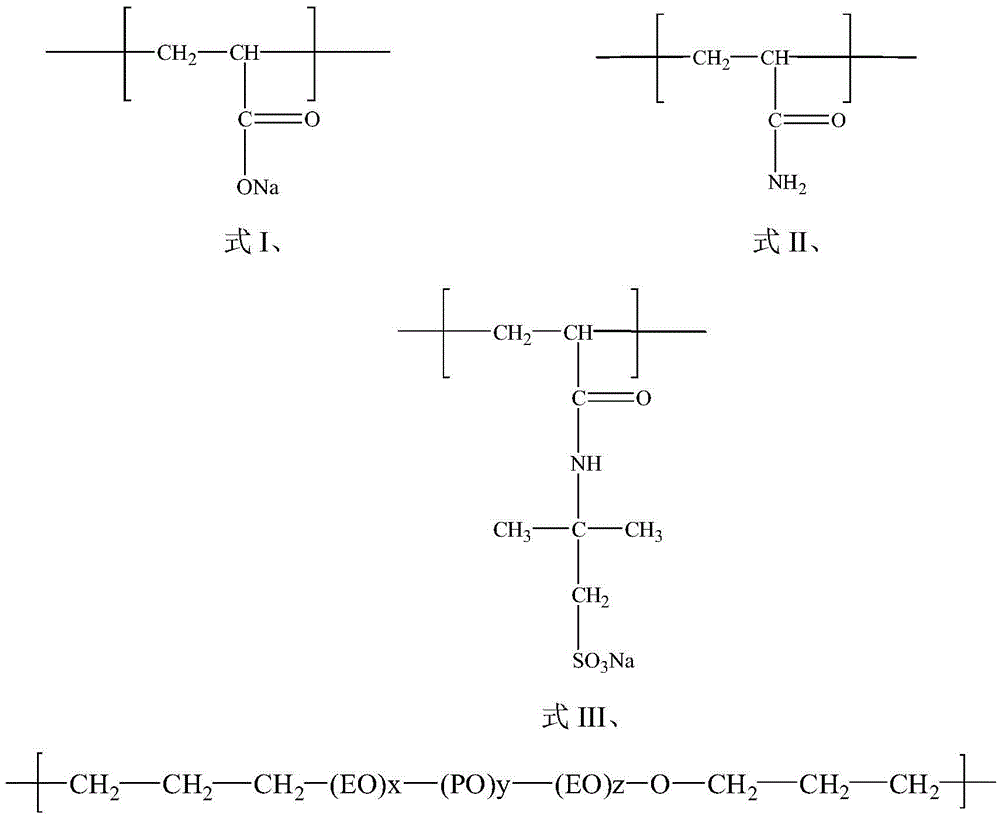

[0054] Add the reaction monomer acrylamide, acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid and diallyl polyether into water to make an aqueous solution, and use a 30% sodium hydroxide solution to adjust the pH of the system to 7.0 to 7.5, pass nitrogen gas for 20 minutes to obtain the aqueous phase; wherein, the structural formula of the bisallyl polyether is shown in the following formula VI:

[0055]

[0056] In formula VI, EO is -OCH 2 CH 2 -(Oxiranyl), PO is -OCH(CH 3 )CH 2 -(glycidyl group); 0≤x<55, 0≤y≤10, 0≤z≤16, x, y, and z are not 0 at the same time;

[0057] 2) Add the aqueous phase obtained in step 1) dropwise into the oil phase of the closed reactor, st...

experiment example 1

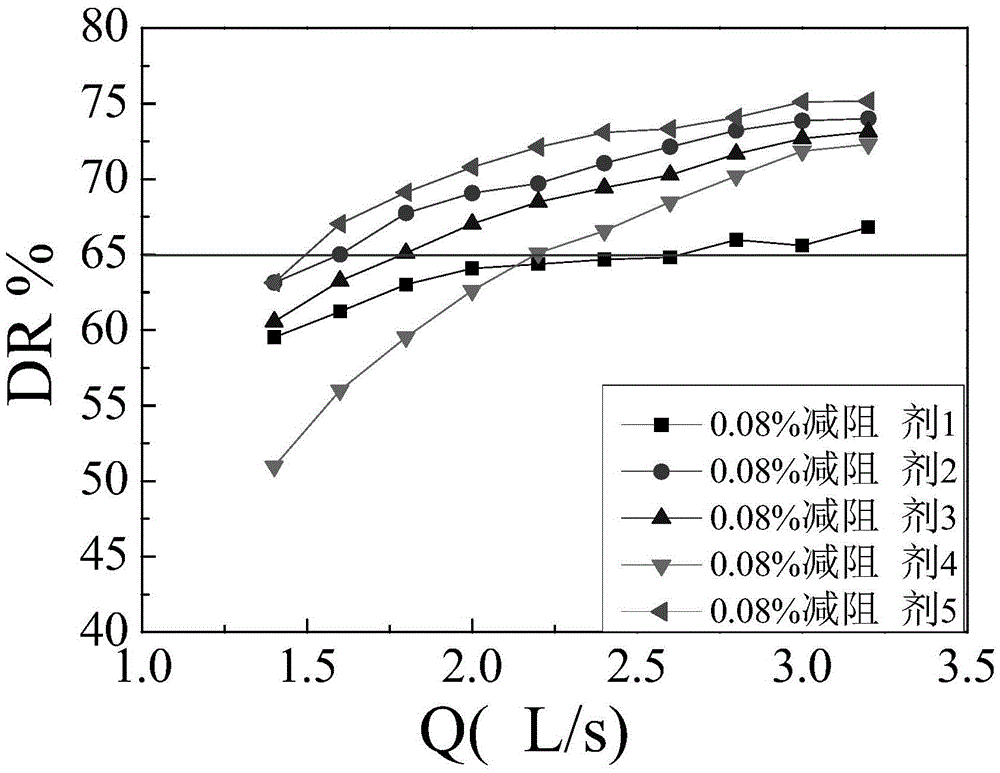

[0070] In this experimental example, the drag reducing performance of the drag reducing agents obtained in Examples 1-4 and Comparative Example was tested. The detection method is to add the obtained drag reducer to clear water so that the mass percentage of the multi-component copolymer is 0.06% to 0.15%, and to calculate the drag reduction rate by testing the pressure difference between two points before and after adding the drag reducer in clear water. Drag reduction effect evaluation. The formula for calculating the drag reduction rate is as follows:

[0071] D R % = ΔP 0 - ΔP D R ΔP 0 × 100 % - - - ( 1 ...

experiment example 2

[0077] In this experimental example, the gel-breaking performance of the drag reducer obtained in Examples 1-4 and Comparative Example was tested. The detection method is that the obtained drag reducer is added to clear water so that the mass percentage of the multi-polymer copolymer is 0.12%, and the mixture is obtained; 100g of the obtained mixture is weighed respectively, and 0.5g of the ammonium persulfate solution with a mass concentration of 10% is added, Placed at the set temperature, the change of the apparent viscosity of the test system is used to evaluate the breaking performance. The test results are shown in Table 2.

[0078] The gel-breaking performance detection result of the drag reducer obtained in table 2 embodiment 1-4 and comparative example

[0079]

[0080] It can be seen from Table 2 that compared with the comparative example, the initial apparent viscosity of the drag reducer obtained in Examples 1-4 is relatively large, and the apparent viscosity d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com