Preparation method and application of hafnium carbide precursor impregnation liquid

A technology of precursor and impregnation solution, which is applied in the field of preparation of hafnium carbide modified C/C composite materials, can solve the problem of low bonding strength, achieve the effect of broadening the application range and improving high temperature ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

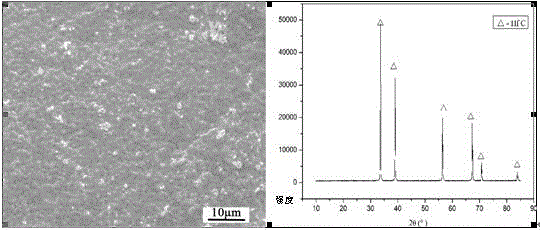

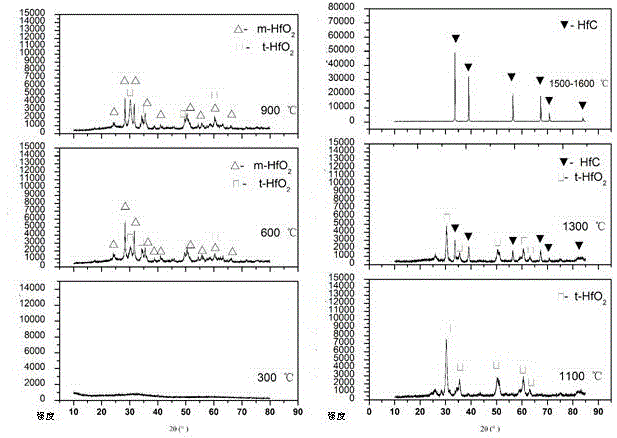

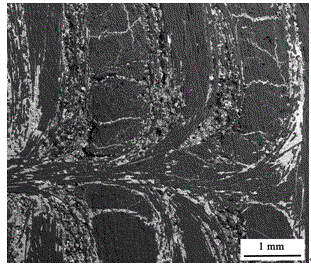

Image

Examples

Embodiment 1

[0022] Under the protection of nitrogen atmosphere, add 32g (0.1mol) of hafnium tetrachloride in a 250ml three-necked flask with mechanical stirring, add 100ml of xylene as the solvent, cool the reaction system to below 0℃, and then slowly add 24ml (0.4 mol) Dehydrated ethanol, react for 3 hours under low temperature protection, transfer the reaction solution to a 250ml beaker, add 60ml of distilled water, stir at room temperature for 1 hour, extract the organic phase in the reaction solution with dichloromethane to enrich the organic phase 20g of anhydrous magnesium sulfate was added to the mixture, allowed to stand for 6 hours, filtered, and xylene was distilled out at 90°C to obtain 22.1g of light yellow liquid.

Embodiment 2

[0024] Under the protection of nitrogen atmosphere, 32g (0.1mol) hafnium tetrachloride was added to a 250ml three-necked flask with mechanical stirring, 100ml xylene was added as the reaction solvent, the reaction system was cooled to below 0°C, and then 31ml ( 0.4mol) Propanol, react for 3 hours under low temperature protection, transfer the reaction solution to a 400ml beaker, add 60ml of distilled water, stir at room temperature for 1 hour, extract the organic phase in the reaction solution with dichloromethane to enrich the organic phase Add 20 g of anhydrous magnesium sulfate to the mixture, let it stand for 6 hours, filter, and distill off xylene at 90°C to obtain 24.8 g of light yellow liquid.

Embodiment 3

[0026] Under the protection of nitrogen atmosphere, 32g (0.1mol) hafnium tetrachloride was added to a 250ml three-necked flask with mechanical stirring, 100ml xylene was added as the reaction solvent, the reaction system was cooled to below 0℃, and then 43ml ( 0.4mol) Cyclohexanol, react for 3 hours under low temperature protection, transfer the reaction solution to a 400ml beaker, add 60ml of distilled water, stir at room temperature for 1 hour, extract the organic phase in the reaction solution with dichloromethane, Add 20 g of anhydrous magnesium sulfate to the phase, let it stand for 6 hours, filter, and distill off xylene at 90°C to obtain 30.2 g of light yellow liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com