Method for preparing novel foaming thermoplastic polyurethane elastomer material

A technology of plastic polyurethane and elastomer materials, which is applied in the field of preparation of foamed thermoplastic polyurethane elastomer materials, can solve the problems affecting the yield, shrinkage of molded products, and lower density of molded products, and achieve low production cost, pollution-free process, The effect of solving material application problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

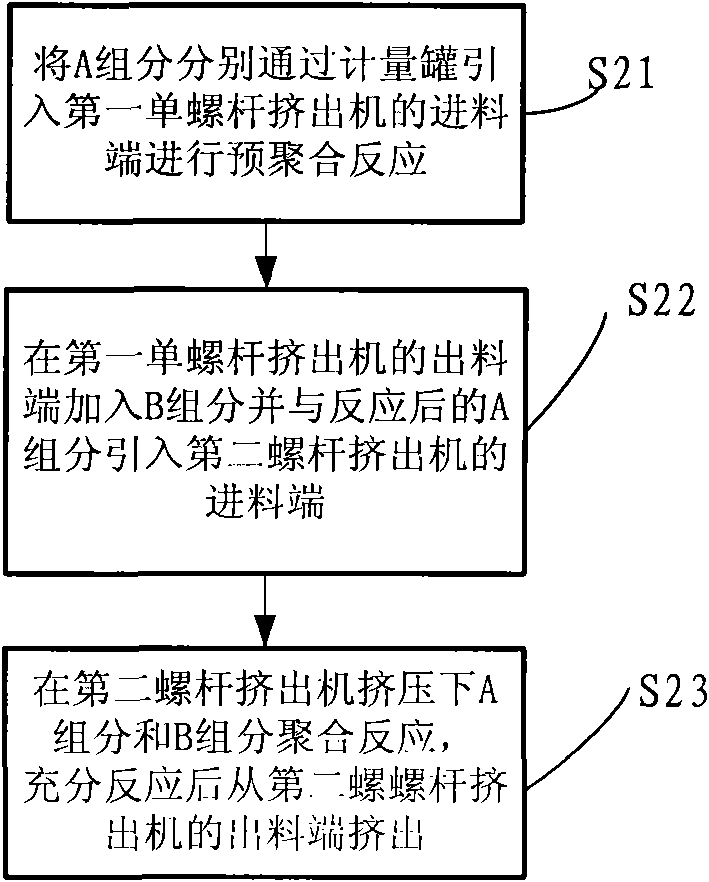

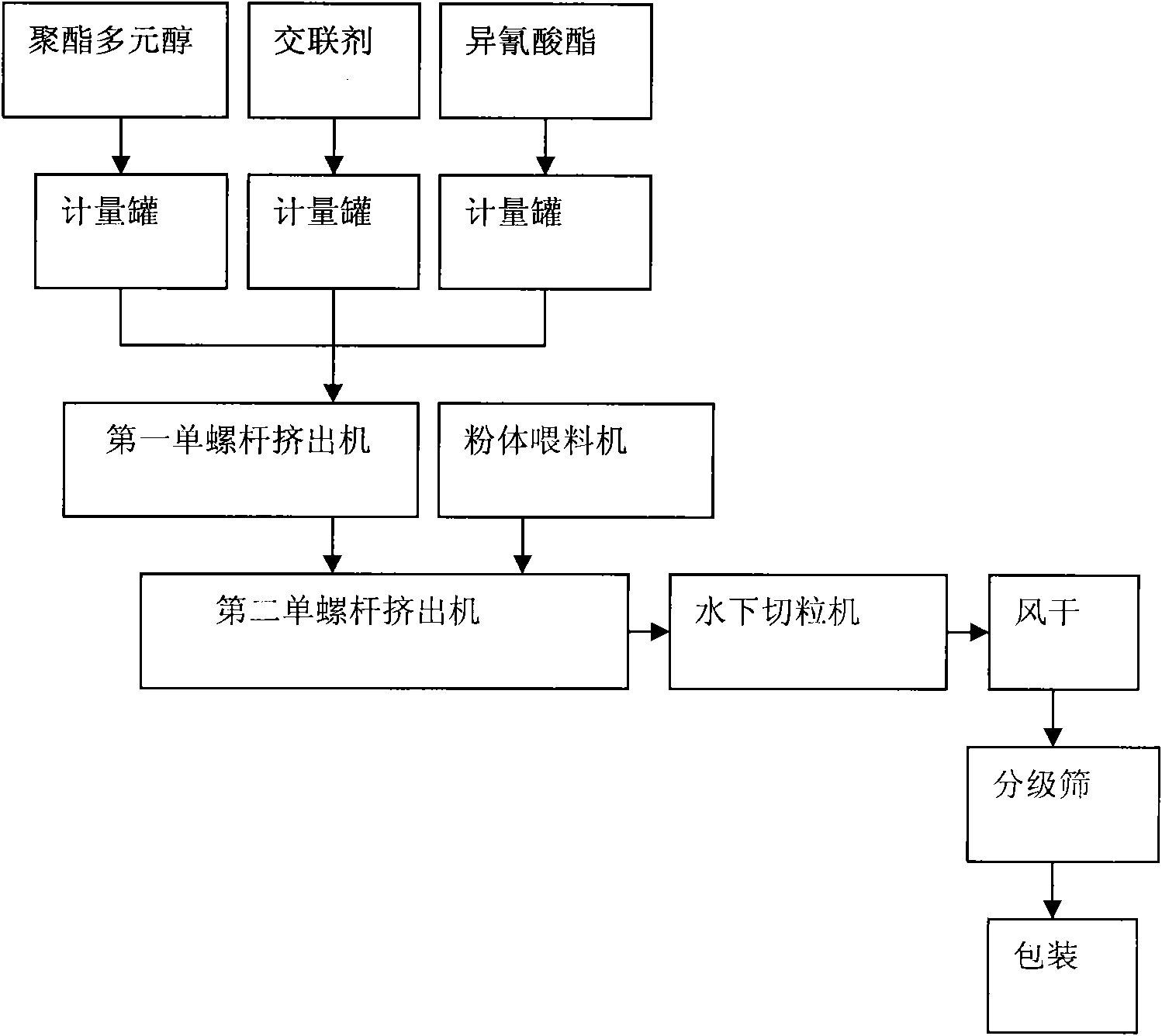

[0022] see figure 1 , figure 1 is a flow chart of the first embodiment of the preparation method of the novel foamed thermoplastic polyurethane elastomer material (novel F-TPU material) of the present invention. Its preparation method comprises the following steps:

[0023] Step S21, introducing component A into the feeding end of the first single-screw extruder through a metering tank for prepolymerization, component A including polyester polyol, crosslinking agent and isocyanate;

[0024] Step S22, adding B component at the discharge end of the first single-screw extruder and introducing the reacted A component into the feed end of the second screw extruder, wherein B component includes: catalyst, foaming aid agent, water, surfactant, triisocyanate, sulfur-assisting agent and foaming agent;

[0025] Step S23, under the extrusion of the second screw extruder, component A and component B polymerize and react, and extrude from the discharge end of the second screw extruder a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com