A kind of preparation method of nanocrystalline glass ceramics

A glass ceramic and nanocrystalline technology, which is applied in the field of preparing nanocrystalline glass ceramics by microwave heat treatment, can solve the problems of long crystallization time, high raw material cost, low energy consumption, etc., and achieves fast heating and sintering speed, fast heating speed, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one: A kind of method for preparing nanocrystalline glass ceramics

[0035] 1) Taking the basic glass composition in Table 1 as an example, make a glass product, then send the glass product into a microwave oven to heat up, and keep it at 560°C for 20 minutes;

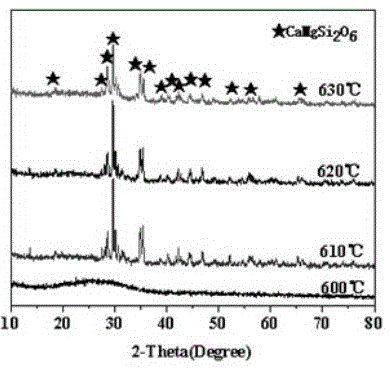

[0036] 2) Continue heating the glass product to 630°C, keep it warm for 25 minutes, and carry out microwave heat treatment in the process of crystal nucleus formation;

[0037] 3) On the basis of the microwave heat treatment of the crystal nucleus formation process, the microwave heat treatment of the crystal nucleus growth is carried out on the glass products;

[0038] Gradually heat the glass product, the specific heating method is as follows:

[0039] (1) Continue to heat up to 640°C, and keep warm at this temperature for 5 minutes;

[0040] (2) Heat up to 660°C and keep warm for 5 minutes;

[0041] (3) Heat up to 680°C and keep warm for 5 minutes;

[0042] (4) Heat up to 710°C and keep warm ...

Embodiment 2

[0048] Embodiment two: A kind of method for preparing nanocrystalline glass ceramics

[0049] 1) Taking the basic glass composition in Table 1 as an example, make a glass product, then heat it in a microwave oven, and keep it at 570°C for 20 minutes;

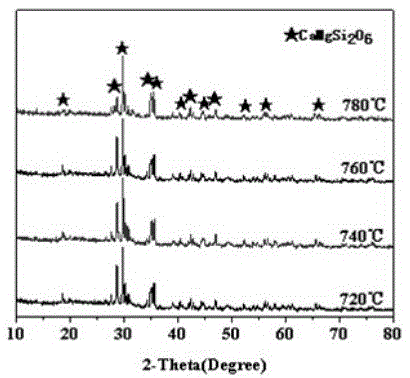

[0050] 2) Raise the temperature to 620°C, keep it warm for 30 minutes, and perform microwave heat treatment in the process of crystal nucleus formation;

[0051] 3) On the basis of the microwave heat treatment of the crystal nucleus formation process, the microwave heat treatment of the crystal nucleus growth is performed on the glass products;

[0052] Gradually heat the glass product, the specific heating method is as follows:

[0053] (1) Heat up to 645°C and keep warm for 4 minutes;

[0054] (2) Heat up to 652°C and keep warm for 4 minutes;

[0055] (3) Heat up to 672°C and keep warm for 4 minutes;

[0056] (4) Heat up to 702°C and keep warm for 4 minutes;

[0057](5) Heat up to 742°C and keep warm for 4 minutes;

[...

Embodiment 3

[0060] Embodiment three: A kind of method for preparing nanocrystalline glass ceramics

[0061] 1) Taking the basic glass composition in Table 1 as an example, make a glass product, then heat it in a microwave oven, and keep it at 580°C for 20 minutes;

[0062] 2) Continue to heat up to 610°C, keep it warm for 35 minutes, and carry out microwave heat treatment in the process of crystal nucleus formation;

[0063] 3) On the basis of the microwave heat treatment of the crystal nucleus formation process, the glass product is subjected to the microwave heat treatment of the crystal nucleus growth.

[0064] Gradually heat the glass product, the specific heating method is as follows:

[0065] (1) Heat up to 645°C and keep warm for 6 minutes;

[0066] (2) Heat up to 655°C and keep warm for 6 minutes;

[0067] (3) Heat up to 675°C and keep warm for 6 minutes;

[0068] (4) Heat up to 715°C and keep warm for 6 minutes;

[0069] (5) Heat up to 745°C and keep warm for 6 minutes;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com