Magnetic separation method of chlorella

A magnetic separation and chlorella technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, single-cell algae, etc., can solve the problems of large influence of ionic strength, large dosage, complex material synthesis, etc., and achieve recovery process Simple and effective, reduced production costs, and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

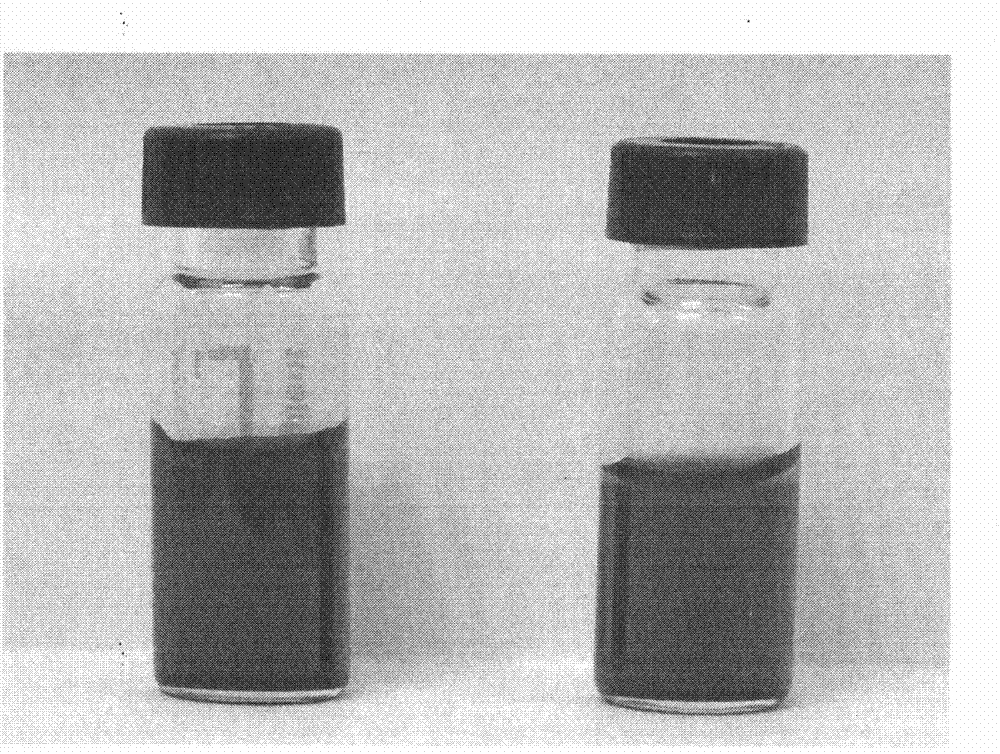

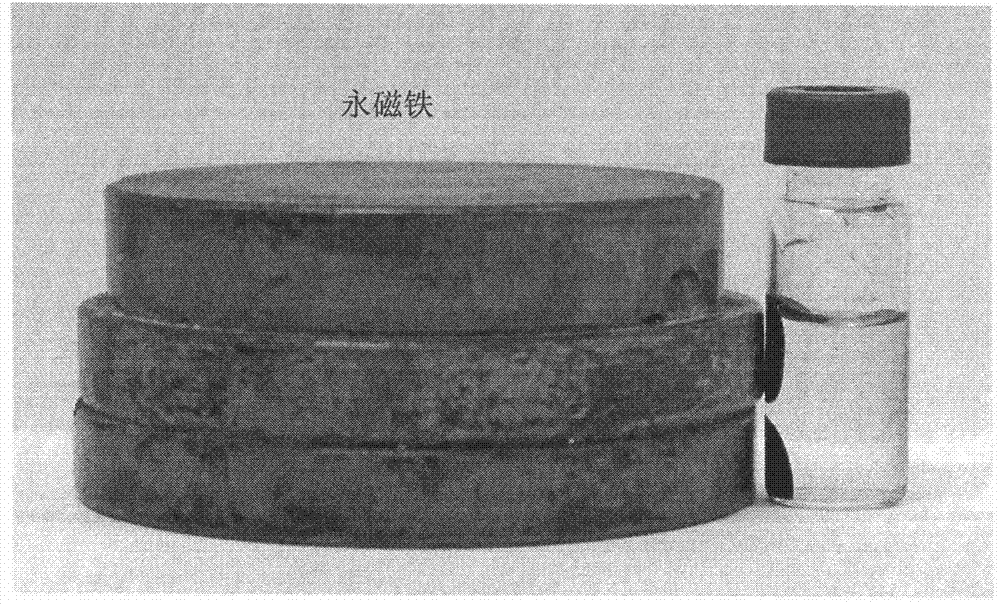

[0056] The present invention utilizes the magnetic separation method of chlorella to carry out the magnetic separation of chlorella and reclaim and regenerate Fe 3 o 4 Nanoparticle magnetic medium, the method steps are as follows:

[0057] (1) Fe 3 o 4 Nanoparticles are dispersed in deionized water to form a stable suspension, prepared into a magnetic separation medium with a concentration of 3% (w / v), and then put into a refrigerator for future use.

[0058] (2) Put the obtained chlorella culture solution into a stirred reactor, add a magnetic separation medium at a speed of 300 rpm, the amount of the magnetic separation medium is 0.04% (w / v), and the stirring time is 2 minutes.

[0059] (3) Remove the supernatant after the magnetic separation, collect the polymer of the chlorella cells and the magnetic medium obtained by separation, the recovery rate of the chlorella reaches 99.2%; the polymer of the chlorella cells and the magnetic medium is used 5 times The volume of t...

Embodiment 2

[0065]Adopt the chlorella magnetic separation method and the magnetic medium recovery method of the present invention, carry out Fe in the chlorella magnetic separation 3 o 4 The recovery of nanoparticles, the steps are as follows:

[0066] (1) Fe 3 o 4 Nanoparticles are dispersed in deionized water to form a stable suspension, prepared into a magnetic separation medium with a concentration of 2% (w / v), and then put into a refrigerator for further storage.

[0067] (2) Put the obtained chlorella culture solution into a stirred reactor, add a magnetic separation medium at a speed of 200 rpm, the amount of the magnetic separation medium is 0.02% (w / v), and the stirring time is 3 minutes.

[0068] (3) Remove the supernatant after the magnetic separation, collect the polymer of the chlorella cells and the magnetic medium obtained by separation, the recovery rate of the chlorella reaches 99.5%; the polymer of the chlorella cells and the magnetic medium is used 4 times The volum...

Embodiment 3

[0072] Adopt the chlorella magnetic separation method and the magnetic medium recovery method of the present invention, carry out Fe in the chlorella magnetic separation 3 o 4 The recovery of nanoparticles, the steps are as follows:

[0073] (1) Fe 3 o 4 The nanoparticles are dispersed in deionized water to form a stable suspension, prepared into a magnetic separation medium with a concentration of 5% (w / v), and then put into a refrigerator for further storage.

[0074] (2) Put the obtained chlorella culture solution into a stirred reactor, add a magnetic separation medium at a speed of 400 rpm, the amount of the magnetic separation medium is 0.05% (w / v), and the stirring time is 1 minute.

[0075] (3) Remove the supernatant after the magnetic separation, collect the microalgae cell and the polymer of the magnetic medium obtained by separation, the recovery rate of Chlorella reaches 99.1%; the polymer of the Chlorella cell and the magnetic medium is used 6 times The polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com