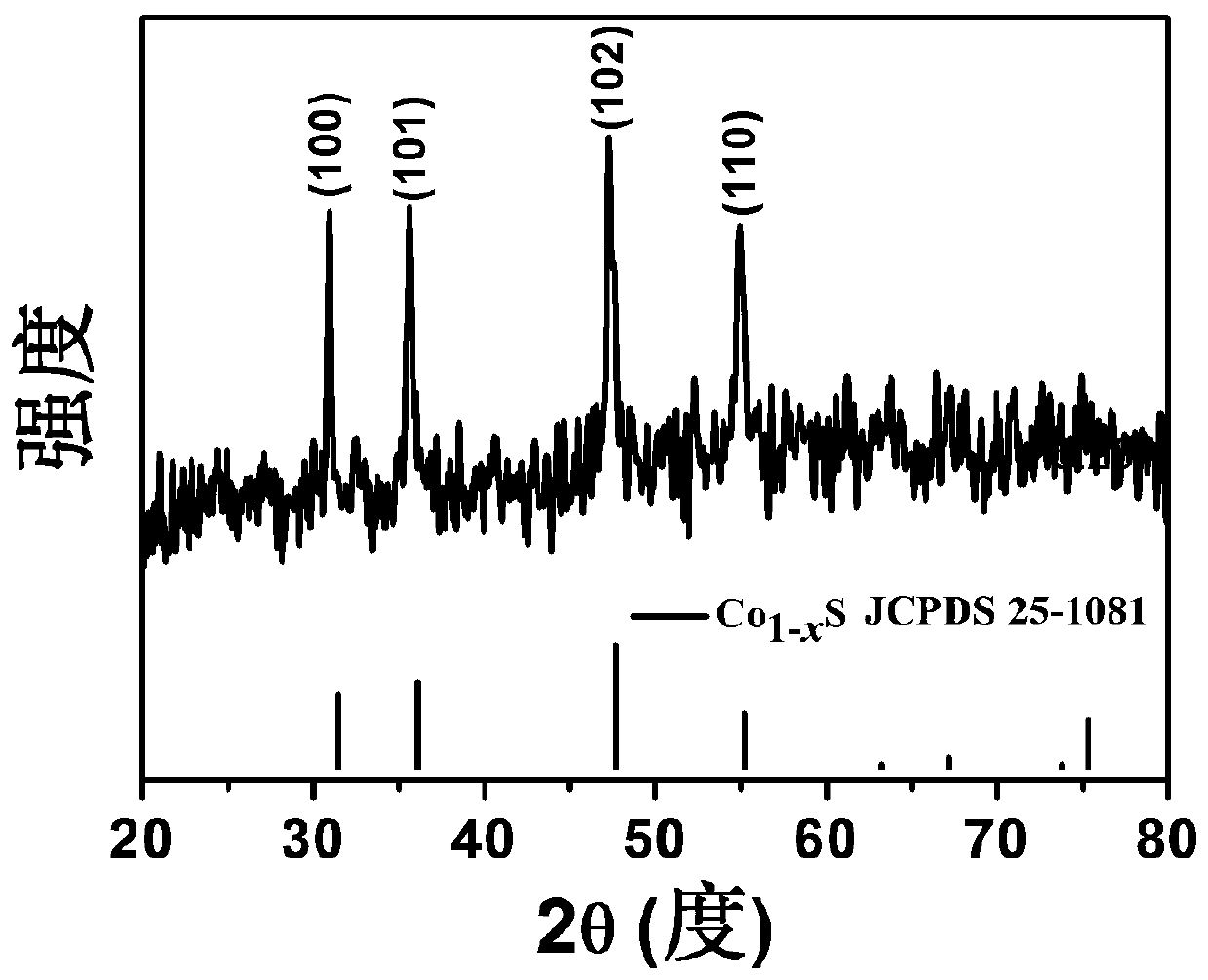

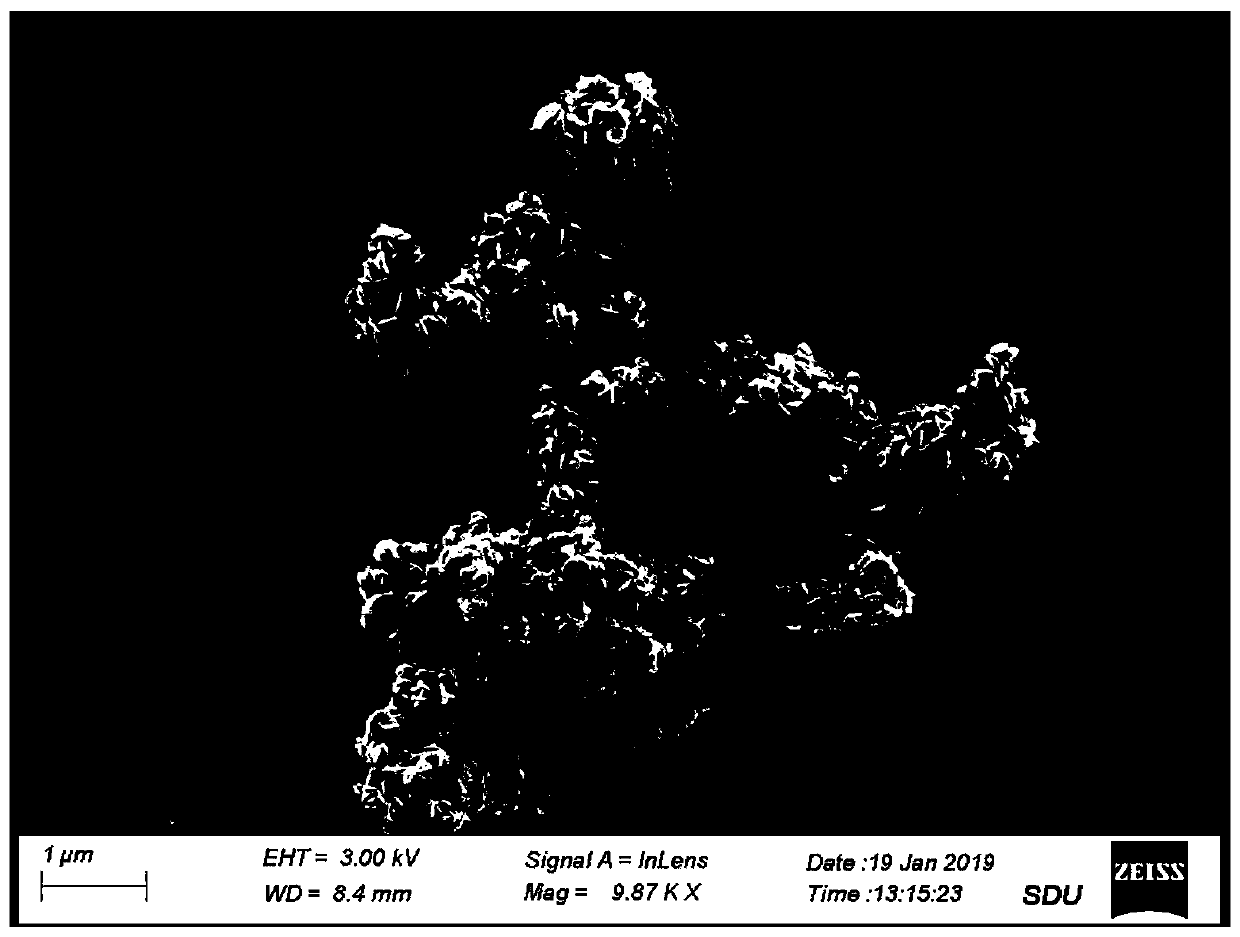

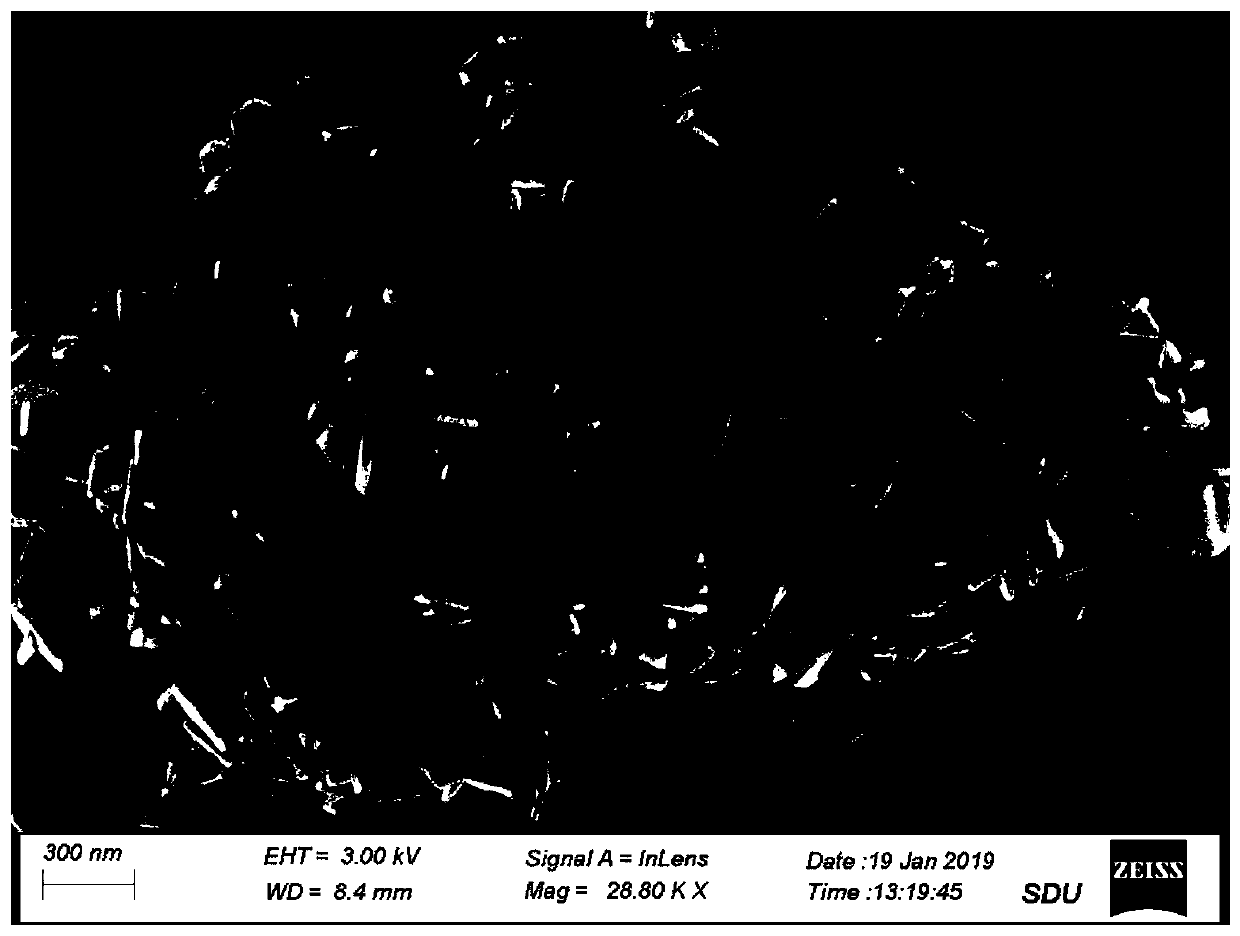

Preparation method of cobalt sulfide Co<1-x>S hexagonal sheet aggregate material

A co1-xs, sulfide technology, applied in cobalt compounds, chemical instruments and methods, cobalt sulfide, etc., can solve the problems of complex preparation process and complex preparation process, and achieve simple and easily controllable preparation process, large surface area, no process. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A cobalt sulfide Co 1-x The preparation method of S hexagonal sheet aggregate material comprises steps as follows:

[0039]Add 1.1897g of cobalt chloride to 60mL of distilled water, stir in a water bath at 35°C, stir evenly, add 1.903g of thiourea and 0.5g of polyvinylpyrrolidone while stirring, and keep stirring at 35°C for 30 minutes to make the cobalt chloride , thiourea, and polyvinylpyrrolidone were completely dissolved to obtain a mixed solution; the pH of the mixed solution was adjusted to 0.7 with 1mol / L hydrochloric acid solution, and the adjusted pH solution was transferred to a reaction kettle, sealed, and placed in an oven at 160°C After the reaction was completed, the reaction kettle was naturally cooled to room temperature, and the supernatant in the reaction kettle was removed. The product was washed with water and ethanol for 3 times respectively, and then dried in a 60°C oven for 8 hours to obtain a black The powder product is cobalt sulfide Co 1-x S ...

Embodiment 2

[0045] A cobalt sulfide Co 1-x The preparation method of S hexagonal sheet aggregate material comprises steps as follows:

[0046] Add 0.7472g of cobalt acetate into 65mL of mixed solvent (the volume ratio of distilled water and ethylenediamine is 12:1), stir in a water bath at 35°C, stir evenly, add 0.4446g of ammonium thiosulfate, 0.01g of ten Hexaalkyltrimethylammonium bromide was continuously stirred for 30 minutes at 35°C, so that cobalt acetate, ammonium thiosulfate and cetyltrimethylammonium bromide were completely dissolved to obtain a mixed solution; the mixed solution was transferred to In the reaction kettle, seal it, put it in an oven, and react at 200 ° C for 26 hours. After the reaction, the reaction kettle is naturally cooled to room temperature, and the supernatant in the reaction kettle is removed. The product is washed with water and ethanol for 3 times respectively. Put it in an oven at 80°C and dry it for 10 hours, and the obtained black powder product is ...

Embodiment 3

[0048] A cobalt sulfide Co 1-x The preparation method of S hexagonal sheet aggregate material comprises steps as follows:

[0049] Add 0.8328g of cobalt chloride to 65mL of mixed solvent (the volume ratio of distilled water and ethylenediamine is 13:1), stir in a water bath at 35°C, stir evenly, add 0.5533g of sodium thiosulfate while stirring, 0.01g Polypyrrole, keep stirring at 35°C for 30 minutes, so that cobalt chloride, sodium thiosulfate and polypyrrole are completely dissolved to obtain a mixed solution; transfer the mixed solution to a reaction kettle, seal it, put it in an oven, and heat it at 200°C After the reaction was completed, the reaction kettle was naturally cooled to room temperature, and the supernatant in the reaction kettle was removed. The product was washed with water and ethanol for 3 times respectively, and then dried in a 60°C oven for 10 hours to obtain a black The powder product is cobalt sulfide Co 1-x S hexagonal sheet aggregate material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com