A pollution-free preparation process of a wide temperature coal-to-natural gas methanation catalyst

A methanation catalyst and coal-to-natural gas technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of waste water and gas discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

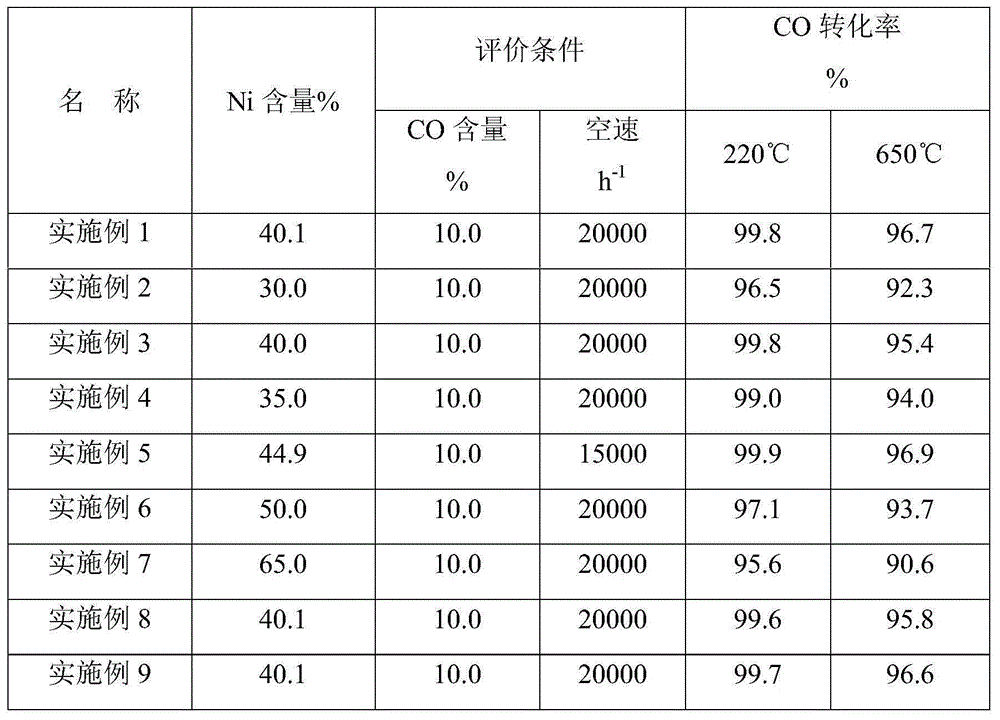

Examples

Embodiment 1

[0034] 1. Take 786g of nickel nitrate and dissolve it in 5400g of deionized water, then add 270g of isopropanol to get the bottom solution;

[0035] 2. Add MgAl to the bottom liquid 2 o 4 142g of porous magnesium aluminate is fully beaten;

[0036] 3. Preheat the slurry to 90°C;

[0037] 4. Add 95g of carbonyl nickel powder;

[0038] 5. Inject air into the hydrogen peroxide storage tank containing 2.0 mol at a rate of 0.5 L / min to obtain air saturated with hydrogen peroxide;

[0039] 6. Pass the above-mentioned air saturated with hydrogen peroxide into the slurry in step 4);

[0040] 7. After the hydrogen peroxide volatilizes, age the reacted slurry at 80°C for 12 hours, and then filter to obtain a filter cake;

[0041] 8. The filter cake is dried at 80°C, crushed, pressed into tablets, and roasted at 550°C to obtain a wide-temperature coal-to-natural gas methanation catalyst;

[0042] 9. The air from step 6) is circulated repeatedly by the fan until the hydrogen peroxid...

Embodiment 2

[0046] 1. Take 2600g nickel nitrate and dissolve it in 5400g deionized water, then add 80g tert-butanol to get the bottom solution;

[0047] 2. Add MgAl to the bottom liquid 2 o 4 142g of porous magnesium aluminate and 142g of CeO 2 Fully beat;

[0048] 3. Preheat the slurry to 60°C;

[0049] 4. Add 122g of sponge nickel powder;

[0050] 5. Pass air into the hydrogen peroxide storage tank containing 2.5 mol at a rate of 1.5 L / min to obtain air saturated with hydrogen peroxide;

[0051] 6. Pass the above-mentioned air saturated with hydrogen peroxide into the slurry in step 4);

[0052] 7. After the hydrogen peroxide volatilizes, age the reacted slurry at 60°C for 12 hours, and then filter to obtain a filter cake;

[0053] 8. The filter cake is dried at 200°C, crushed, pressed into tablets, and roasted at 800°C to obtain a wide-temperature coal-to-natural gas methanation catalyst;

[0054] 9. The air from step 6) is circulated repeatedly by the fan until the hydrogen per...

Embodiment 3

[0058] 1. Take 1571g of nickel nitrate and dissolve it in 5400g of deionized water, then add 108g of neopentyl alcohol to get the bottom solution;

[0059] 2. Add 213g of La to the above bottom liquid 2 o 3 Fully beat;

[0060]3. Preheat the slurry to 100°C;

[0061] 4. Add 142g of sponge nickel powder;

[0062] 5. Pass air into the hydrogen peroxide storage tank containing 3.0 mol at a rate of 1.5 L / min to obtain air saturated with hydrogen peroxide;

[0063] 6. Pass the above-mentioned air saturated with hydrogen peroxide into the slurry in step 4);

[0064] 7. After the hydrogen peroxide volatilizes, age the reacted slurry at 100°C for 1 hour, and then filter to obtain a filter cake;

[0065] 8. The filter cake is dried at 120°C, crushed, pressed into tablets, and roasted at 600°C to obtain a wide-temperature coal-to-natural gas methanation catalyst;

[0066] 9. The air from step 6) is circulated repeatedly by the fan until the hydrogen peroxide content is less than 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com