Preparing method of niobate photocatalyst Bi3Nb17O47 and application of niobate photocatalyst Bi3Nb17O47

A technology of photocatalysis and photocatalytic materials, applied in the field of preparation of new inorganic photocatalyst materials Bi3Nb17O47, which can solve the problems of low electron-hole recombination rate and achieve the effect of simple preparation method, small particles and good ultraviolet response ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] According to the chemical formula Bi 3 Nb 17 o 47 , respectively weigh bismuth oxide Bi 2 o 3 : 1.748 g, niobium pentoxide Nb 2 o 5 : 5.63 grams, after adding an appropriate amount of acetone in an agate mortar, mixing and grinding evenly, pre-calcining in an air atmosphere, calcining at 400 ° C for 6 hours, and taking out the sample after natural cooling; After fully mixing and grinding in the bowl with the same method, calcining again in the air atmosphere, calcining at 1150°C for 12 hours, cooling and grinding to obtain bismuth niobate Bi 3 Nb 17 o 47 Photocatalyst powder.

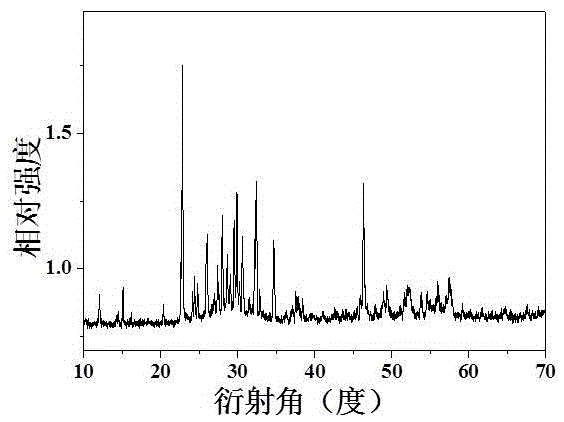

[0042] See attached figure 1 , which is the X-ray powder diffraction pattern of the prepared sample according to the technical scheme of this embodiment, and the XRD test results show that the prepared bismuth niobate Bi 3 Nb 17 o 47 Good crystallinity, no impurity phase;

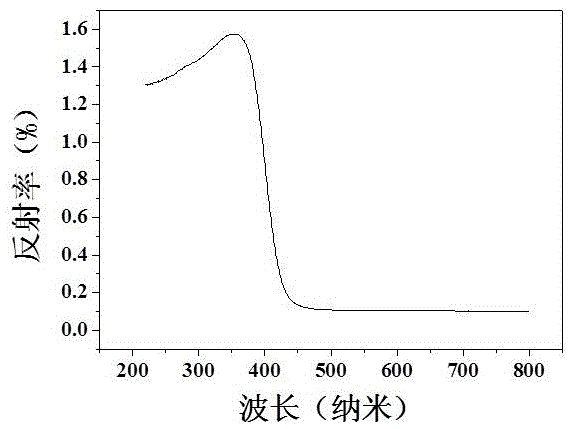

[0043] See attached figure 2 , which is the absorption spectrum of the sample prepared according to the techn...

Embodiment 2

[0048] According to the chemical formula Bi 2 Nb 10 o 28 , respectively weigh bismuth nitrate Bi(NO 3 ) 3 ·6H 2 O: 1.398 g, niobium pentoxide Nb 2 o 5 : 4.522 grams, after adding an appropriate amount of acetone in an agate mortar, mixing and grinding evenly, pre-calcining in an air atmosphere, calcining at 600 ° C for 8 hours, and taking out the sample after natural cooling; Method Mix well and grind evenly, calcinate again in air atmosphere, calcinate at 800°C for 9 hours, cool and grind to obtain bismuth niobate Bi 3 Nb 17 o 47 catalyst powder.

[0049] Its main structural appearance, absorption spectrum, SEM collection of illustrative plates, the degradation rate to methylene blue and the kinetic curve of degrading methylene blue are similar to embodiment 1.

Embodiment 3

[0051] According to the chemical formula Bi 3 Nb 17 o 47 , respectively weigh bismuth hydroxide Bi(OH) 3 : 1.165 g, niobium pentoxide Nb 2 o 5 : 3.768 grams, add an appropriate amount of acetone to the agate mortar, mix and grind evenly, then pre-calcine in the air atmosphere, calcined at 550 ° C for 6 hours, after natural cooling, take out the sample and use the same method to fully Mix and grind evenly, calcined again in air atmosphere, calcined at 1000°C for 10 hours, cooled and ground to obtain bismuth niobate Bi 3 Nb 17 o 47 catalyst powder.

[0052] Its main structural appearance, absorption spectrum, SEM collection of illustrative plates, the degradation rate to methylene blue and the kinetic curve of degrading methylene blue are similar to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com