Polyester used for plates and preparing method thereof

A polyester and sheet technology, applied in the field of modified polyester for sheet and its preparation, can solve the problems of unstable polyethylene glycol, no copolyester, affecting product quality, etc., and achieve good product quality and cost-effectiveness. The effect of obvious advantages and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

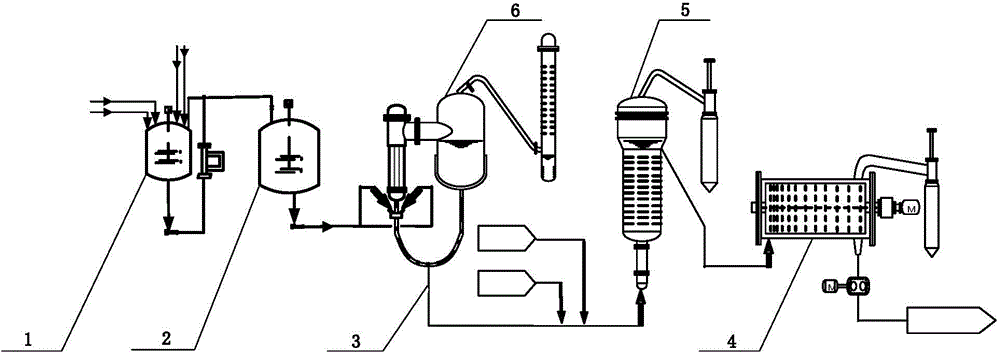

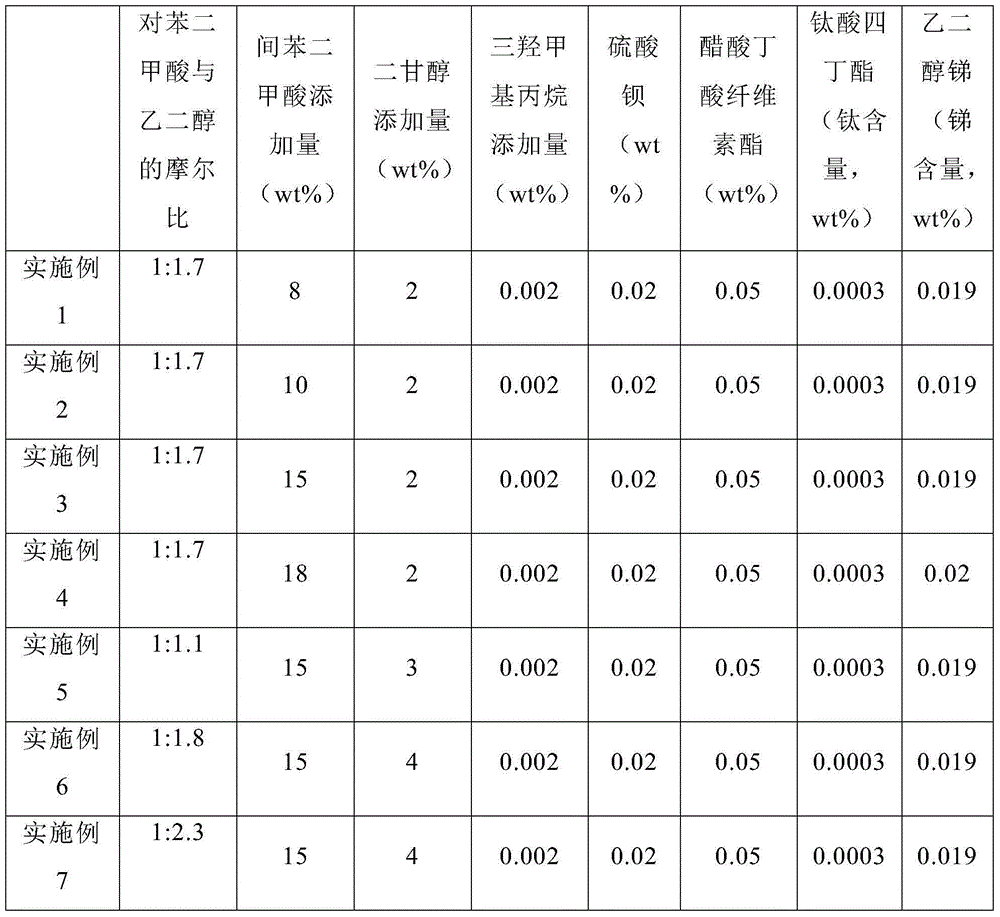

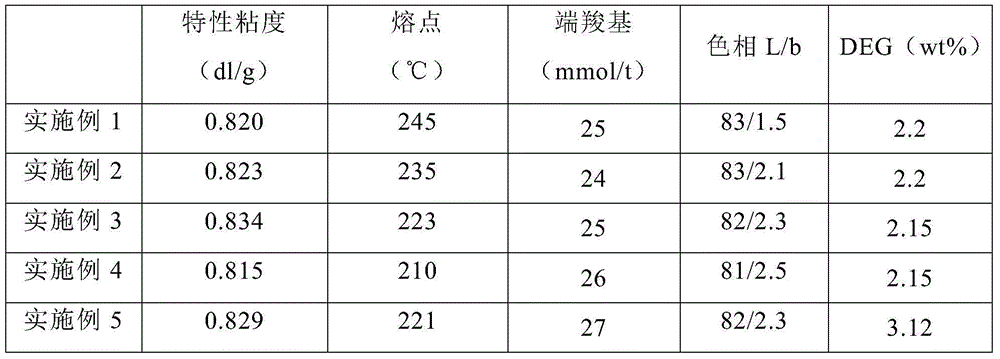

[0041] Terephthalic acid, ethylene glycol, the third component isophthalic acid, the fourth component diethylene glycol, the fifth component trimethylolpropane, heterogeneous inorganic barium sulfate and tetrabutyl titanate, Add it into the slurry mixing tank 1 in proportion to prepare the slurry, and enter the esterification reactor after being metered through the slurry supply tank 2;

[0042] The prepared slurry is injected into the esterification kettle 6, and the esterification reaction is carried out at 250-280°C, 0.05-0.15Mpa to generate bishydroxyethyl terephthalate, and the reaction is carried out until the esterification rate is at least 92%. The reaction process produces The water is separated and removed through a rectification tower;

[0043] In the bishydroxyethyl terephthalate pipeline 3 that imports bishydroxyethyl terephthalate into the upflow type precondensation reactor 5, add hydrophilic modifier cellulose acetate butyrate, antimony series catalyst ethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com