Method for efficient and fast desilication of bauxite

A bauxite and desiliconization technology, applied in the field of bauxite desiliconization, can solve the problems of fluctuation, long dissolution time and high alkali concentration, and achieve the effects of no tailings, short desiliconization time and improved recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

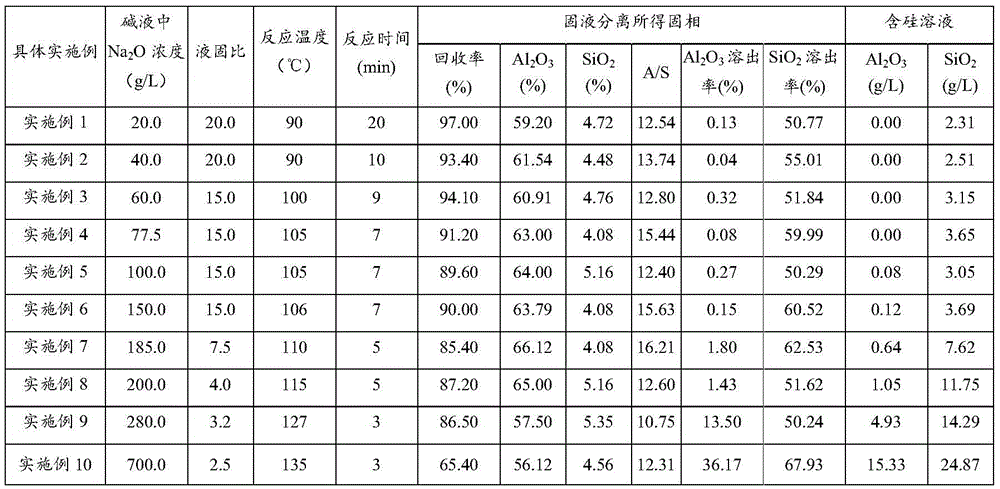

Examples

Embodiment 18

[0042] An efficient and rapid desilication method for diaspore-type bauxite, and the composition analysis results of bauxite are shown in Table 1.

[0043] Silicon dissolution step: mix bauxite with lye to prepare a reaction slurry, the content of sodium oxide in the lye is 77.5g / L, the liquid-solid ratio of the reaction slurry is 20, the grinding of bauxite in the reaction slurry The ore fineness is -200 mesh and the content is 90%. The reaction slurry reacts and dissolves silicon in a microwave reactor. The frequency of the microwave reactor is 2450MHz, the reaction temperature is 80°C, and the reaction time is 5min. After the reaction, the reaction liquid is separated into solid and liquid. The resulting liquid phase is a silicon-containing solution.

[0044] The silicon-containing solution is not desiliconized, and is directly returned for processing the next batch of bauxite, and lye is added to the silicon-containing solution to keep the liquid-solid ratio of the prepare...

Embodiment 19

[0049] An efficient and rapid desilication method for diaspore-type bauxite, and the composition analysis results of bauxite are shown in Table 1.

[0050] Silicon dissolution step: mix bauxite with sodium hydroxide solution to prepare a reaction slurry, the content of sodium oxide in the sodium hydroxide solution is 77.5g / L, the liquid-solid ratio of the reaction slurry is 20, and the aluminum in the reaction slurry The grinding fineness of the earth ore is -200 mesh and the content is 60%. The reaction slurry reacts and dissolves silicon in a microwave reactor. The frequency of the microwave reactor is 2450MHz, the reaction temperature is 70°C, and the reaction time is 10min. Thermal rapid solid-liquid separation, the obtained liquid phase is a silicon-containing sodium hydroxide solution, the obtained solid phase is washed with hot water at 50-100°C, and then undergoes secondary silicon dissolution treatment;

[0051] The obtained solid phase is subjected to secondary silic...

Embodiment 20

[0056] An efficient and rapid desilication method for diaspore-type bauxite, and the composition analysis results of bauxite are shown in Table 6.

[0057] Table 6

[0058] chemical composition Al 2 o 3 SiO 2 A / S Percentage (%) 58.44 17.03 3.43

[0059] Silicon dissolution step: mix bauxite with sodium hydroxide solution to prepare a reaction slurry, the content of sodium oxide in the sodium hydroxide solution is 150g / L, the liquid-solid ratio of the reaction slurry is 10, and the bauxite in the reaction slurry The grinding fineness of the ore is -200 mesh and the content is 95%. The reaction slurry reacts and dissolves silicon in a microwave reactor. The frequency of the microwave reactor is 2450MHz, the reaction temperature is 105°C, and the reaction time is 10min. Rapid solid-liquid separation, the obtained liquid phase is a silicon-containing sodium hydroxide solution, the obtained solid phase is washed with hot water at 100°C, and then subj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com