Catalytic conversion method for producing low-carbon olefin from chlorine-containing plastic oil

A technology of catalytic conversion and plastic oil, which is applied in the treatment of hydrocarbon oil and petroleum industry, etc., can solve the problems of high construction cost of hazardous solid waste landfills, high requirements for equipment materials, and complicated process flow, so as to improve the utilization value and greatly Economic and social benefits, the effect of avoiding the decomposition of hydrocarbon molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

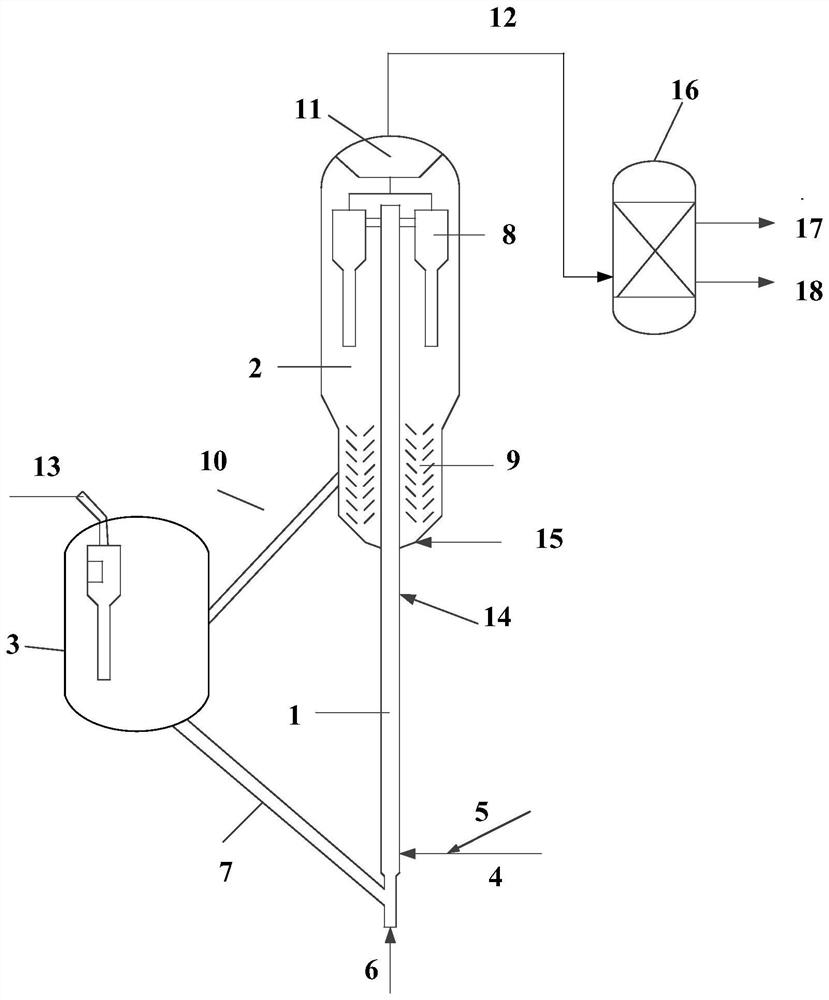

[0070] according to figure 1 The process is tested, and the dechlorination test of chlorine-containing plastic oil A is carried out on the medium-sized device of the riser reactor. The raw material oil is chlorine-containing plastic oil A, and the catalyst is the waste catalyst of the industrial catalytic cracking unit. The waste plastic mixture enters the riser for reaction The hot catalyst in the lower part of the reactor contacts and carries out catalytic decomposition reaction, injects dechlorination agent in the middle and downstream of the reactor, the dosage of dechlorination agent is 2000 mg / kg (waste plastic oil), and reacts with the hydrogen chloride generated in the reactor, the reaction product The reaction product and the spent catalyst enter the closed cyclone separator from the outlet of the reactor, and the reaction product and the spent catalyst are quickly separated, and the reaction product is separated into gas and low-chlorine plastic oil according to the d...

Embodiment 2

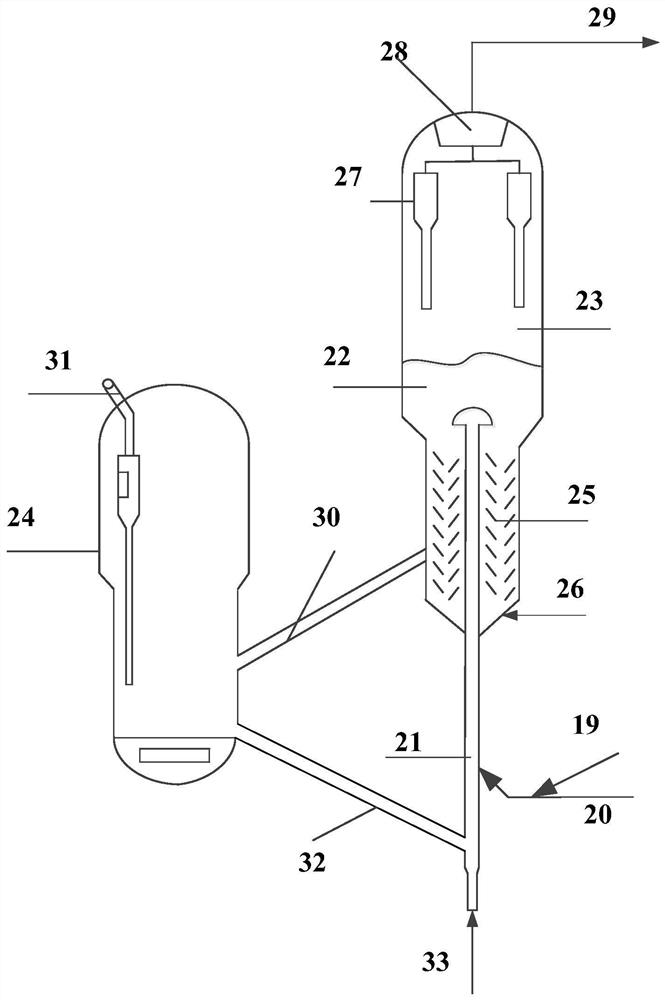

[0078] according to figure 1 and figure 2 The process was tested, and the catalytic conversion reaction test of waste plastic oil was carried out on the medium-sized device of the riser reactor. The raw material was chlorine-containing plastic oil B, and the catalytic decomposition catalyst was the waste catalyst of industrial catalytic cracking unit. Chlorine-containing plastic oil B entered the riser The hot catalyst in the lower part of the reactor contacts and carries out the catalytic decomposition reaction. Inject the dechlorination agent in the lower part of the reactor. The reaction occurs, and the reaction product and the unused catalyst enter the closed cyclone separator from the outlet of the reactor, and the reaction product and the unused catalyst are quickly separated, and the reaction product is separated into cracked gas and low-chlorine plastic oil in the separation system according to the distillation range. The separated gas is returned to the bottom of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com