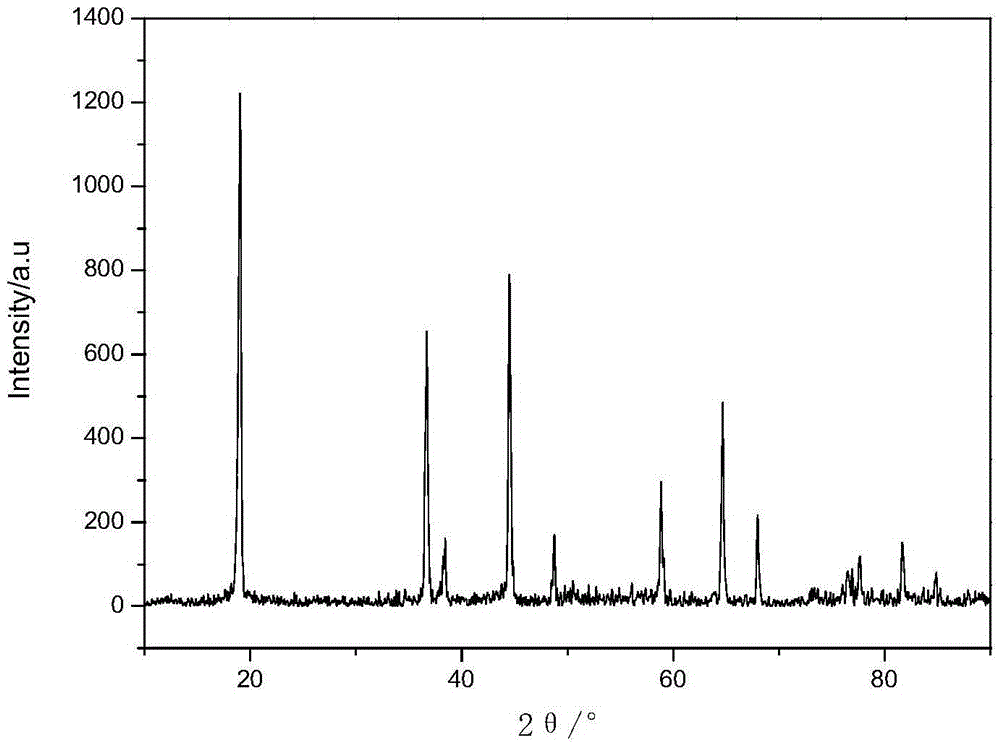

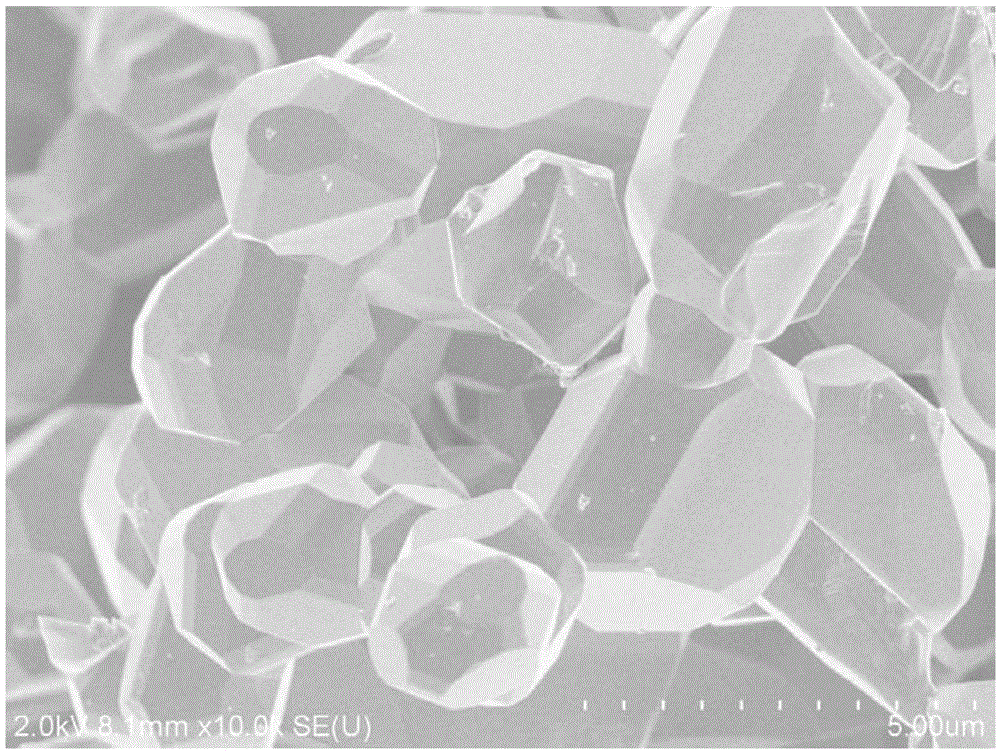

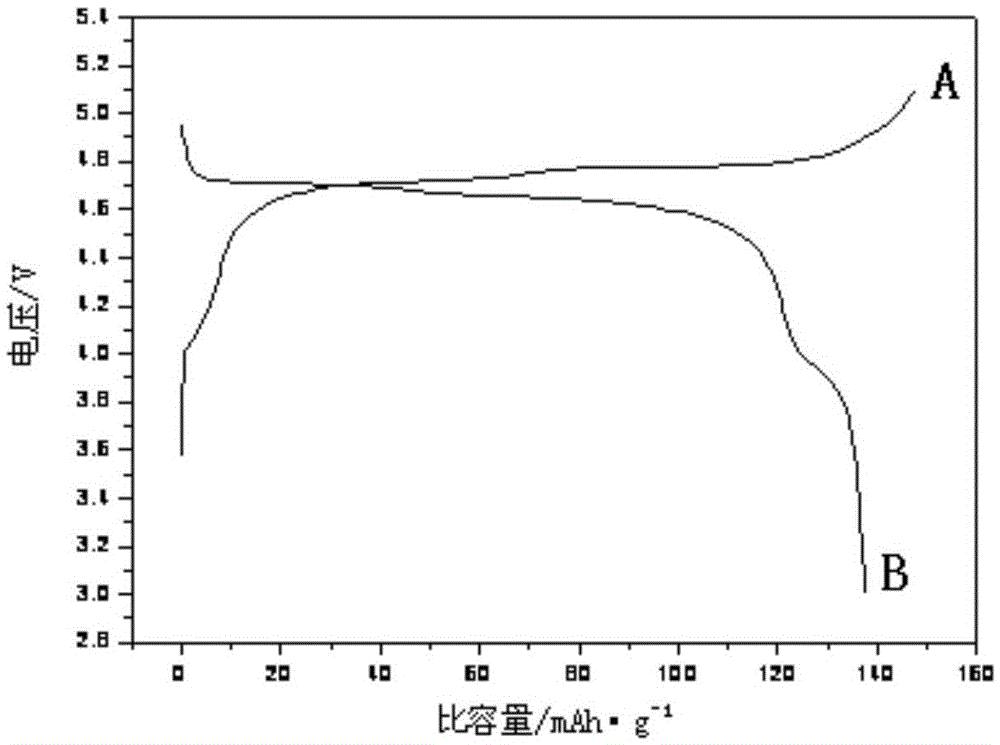

High-voltage lithium oil battery positive electrode material with spinel structure and preparation method of high-voltage lithium oil battery positive electrode material

A lithium-ion battery, spinel structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of low first Coulomb efficiency, poor cycle performance and rate performance, and achieve improved cycle and rate performance, The effect of uniform particles and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment one: the preparation method of the positive electrode material of high-voltage lithium-ion battery with spinel structure, comprises the steps:

[0029] (1) Lithium nitrate, nickel acetate, manganese acetate and aluminum nitrate are 1.076:0.45:1.5:0.025 in molar ratio, fully dissolved with deionized water respectively, each solution after dissolving is mixed in a clean large beaker, Among them, in order to prevent a small amount of volatilization of lithium under high temperature environment, the excess of lithium nitrate is 5%, and finally mixed with citric acid and continuously stirred and added ammonia water to adjust the pH at 7-8, the molar ratio of the total amount of nickel acetate, manganese acetate and aluminum nitrate to citric acid 1:1;

[0030] (2) Under the condition of 80° C., the mixed solution obtained in step (1) was evaporated at a constant temperature for 10 hours at a stirring speed of 200 rpm to obtain a sol;

[0031] (3) Place the sol in a...

Embodiment 2

[0038] Embodiment two: the preparation method of the positive electrode material of high-voltage lithium-ion battery with spinel structure, comprises the following steps:

[0039] (1) Lithium nitrate, nickel acetate, manganese acetate and aluminum nitrate are fully dissolved with deionized water respectively in a molar ratio of 1.10:0.4:1.5:0.05, each solution after dissolving is mixed in a clean large beaker, and Finally, citric acid is mixed in, wherein in order to prevent a small amount of volatilization of lithium under high temperature environment, lithium nitrate is excessively 5%, stirring continuously and adding ammonia water to adjust the pH at 7-8, the total amount of nickel acetate, manganese acetate and aluminum nitrate and the mole of citric acid The ratio is 1:1;

[0040] (2) Under the condition of 80°C, the mixed solution obtained in step (1) was evaporated at a constant temperature for 9 hours under the condition of a stirring speed of 300 rpm to obtain a sol; ...

Embodiment 3

[0047] Embodiment three: the preparation method of the positive electrode material of high-voltage lithium-ion battery with spinel structure, comprises the following steps:

[0048] (1) The molar ratio of lithium nitrate, nickel acetate, manganese acetate and chromium nitrate is 1.10:0.4:1.5:0.05 (wherein in order to prevent a small amount of volatilization of lithium under high temperature environment, lithium nitrate is excessive 5%), respectively with deionized water Dissolve fully, mix each solution after dissolving in a clean large beaker, and finally mix in citric acid, stir constantly and add ammonia water to adjust pH at 7~8, the total amount of described nickel acetate, manganese acetate and chromium nitrate and The molar ratio of citric acid is 1:1;

[0049] (2) Under the condition of 80°C, the mixed solution obtained in step (1) was evaporated at a constant temperature for 9 hours under the condition of a stirring speed of 400 rpm to obtain a sol;

[0050] (3) Put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com