Composite membrane with polymer coating and preparation method of composite membrane

A technology of polymer coating and composite diaphragm, which is applied in the direction of electrical components, circuits, battery pack parts, etc., can solve the problems of polymer coating quality difference, pollute the environment, affect production quality, etc., and achieve the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

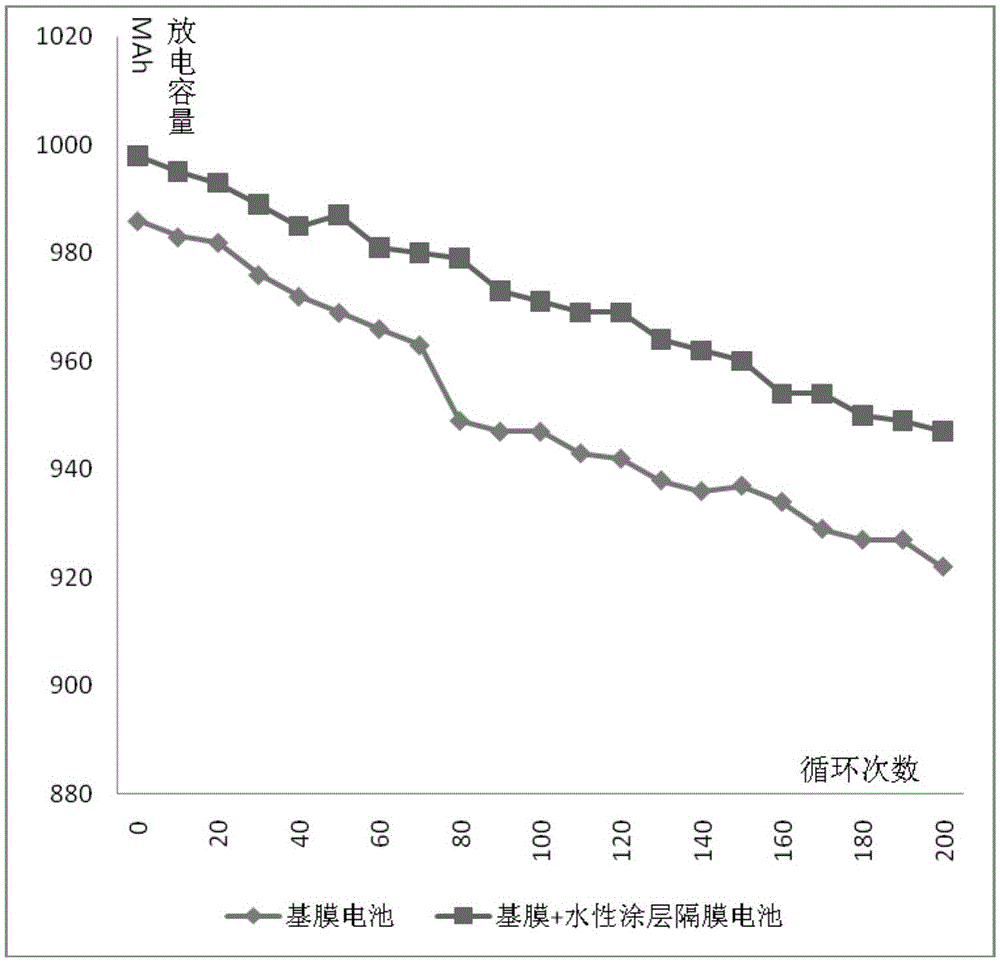

[0028] In the preparation method of the present application, the water-based slurry is used to replace the organic solvent slurry, which avoids the use of organic solvents, is not only safe and environmentally friendly, but also reduces production costs; more importantly, the application adds a suspension to the water-based slurry agent, so that the water-based slurry is not only uniformly dispersed, but also more stable. In mass production, it effectively solves the problem of instability of the water-based slurry over time, and also solves the problem of water-based slurry due to the dispersion of the water-based slurry. Production quality issues caused by uniformity and stability.

[0029] It can be understood that the key of the present application is to add a suspending agent in the water-based slurry. As for other components of the water-based slurry, you can refer to the existing water-based slurry preparation method, as long as the water-based slurry of the suspending a...

Embodiment 1

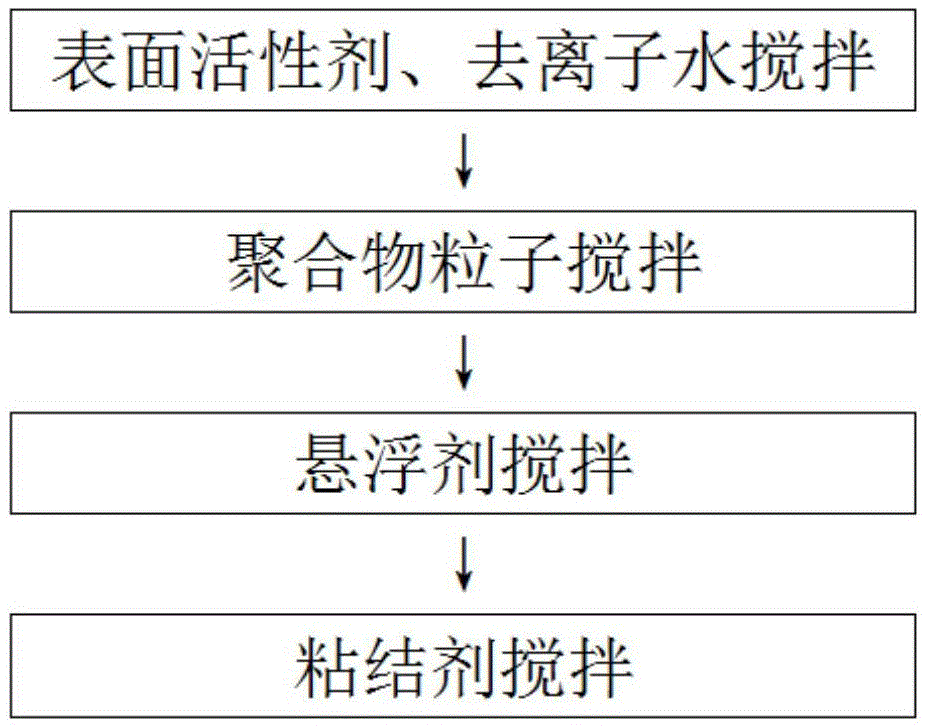

[0032] The water-based slurry in this example is formed by dispersing polymer particles, surfactants, water-based binders and suspending agents in deionized water, wherein the polymer particles are polymethyl methacrylate particles (abbreviated as PMMA), and the surface activity Fluorocarbon surfactant is used as agent, styrene-butadiene rubber is used as water-based binder, and sodium chloride is used as suspending agent. The preparation of aqueous slurry as figure 1 As shown, the specific preparation method of the composite diaphragm is as follows:

[0033] (a) Surfactant and deionized water are added in the stirring tank according to the weight ratio of fluorocarbon surfactant: deionized water=0.015%: 100%, and stirred for 20 minutes to obtain mixed solution I;

[0034] (b) PMMA polymer particles were added to the mixed solution I, stirred for 40 minutes to obtain the mixed solution II, wherein the mass ratio of PMMA to deionized water was 20%:100%;

[0035] (c) Add suspe...

Embodiment 2

[0042]The water-based slurry in this example is formed by dispersing polymer particles, surfactants, water-based binders and suspending agents in deionized water, wherein the polymer particles are polymethyl methacrylate particles (abbreviated as PMMA), and the surface activity Fluorocarbon surfactant is used as agent, styrene-butadiene rubber is used as water-based binder, and ethylene dibromide is used as suspending agent. The specific preparation method of the composite diaphragm is as follows:

[0043] (a) Surfactant and deionized water are added in the stirring tank according to the weight ratio of fluorocarbon surfactant: deionized water=0.015%: 100%, and stirred for 20 minutes to obtain mixed solution I;

[0044] (b) PMMA polymer particles were added to the mixed solution I, stirred for 40 minutes to obtain the mixed solution II, wherein the mass ratio of PMMA to deionized water was 20%:100%;

[0045] (c) Add suspending agent to mixed solution II, stir for 30 minutes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com