Process and device for generating electricity by using LNG cold energy

A process and cold energy technology, which is applied in the field of processes and devices using LNG cold energy for power generation, can solve the problems of large temperature difference of cold energy recovery heat exchanger, large loss of effective energy, complicated process, etc., so as to reduce the loss of effective energy and easily The effect of starting and stopping, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

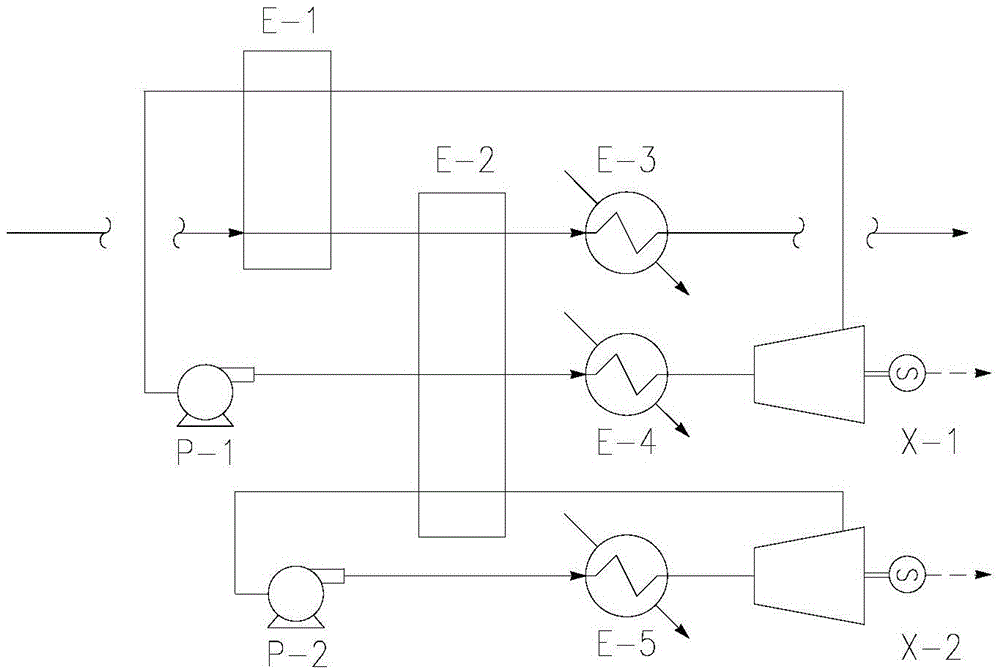

[0028] Such as figure 1 As shown, the LNG boosted by the LNG booster pump (about -160°C ~ -140°C) is reheated and vaporized by the LNG evaporator E-1, and then continues to recover cooling capacity through the LNG heating heat exchanger E-2 , and finally heated by one or more natural gas heat exchangers E-3 to a temperature suitable for sending to the downstream pipeline network (at least 5°C lower than the ambient temperature), and then enters the pipeline network. The cold energy released in this process is recycled to generate electricity through two separate cycles, Cycle 1 and Cycle 2.

[0029]Cycle 1: 5.6 barg, -53.9°C ethylene passes through the LNG evaporator E-1, exchanges heat with the pressurized LNG to take away the cooling capacity, the ethylene in cycle 1 is cooled to about -70°C and liquefied, and then is The ethylene booster pump P-1 is boosted to 23.5 barg. The pressurized ethylene enters the LNG heating heat exchanger E-2, and exchanges heat with the propan...

Embodiment 2

[0033] Such as figure 1 As shown, the LNG boosted by the LNG booster pump (about -160°C ~ -140°C) is reheated and vaporized by the LNG evaporator E-1, and then continues to recover the cooling capacity through the LNG heating heat exchanger, and finally passes through the One or more natural gas heat exchangers E-3 are heated to a temperature suitable for feeding into the downstream pipeline network (at least 5°C lower than the ambient temperature) and enter the pipeline network. The cold energy released in this process is recycled to generate electricity through two separate cycles, Cycle 1 and Cycle 2.

[0034] Cycle 1: 5.6 barg, -53.9°C ethylene passes through the LNG evaporator E-1, exchanges heat with the pressurized LNG to take away the cooling capacity, the ethylene in cycle 1 is cooled to about -90°C and liquefied, and then is The ethylene booster pump P-1 is boosted to 23.5 barg. The pressurized ethylene enters the LNG heating heat exchanger E-2, and exchanges heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com