Flotation desiliconization and desulfurization method of sulfur-containing bauxite

A bauxite and desiliconization technology, applied in flotation, solid separation and other directions, can solve the problems of affecting the bauxite recovery rate, reducing the selectivity of chemicals, poor slurry dispersion performance, etc., to avoid poor dispersion performance, improve sulfur content, the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

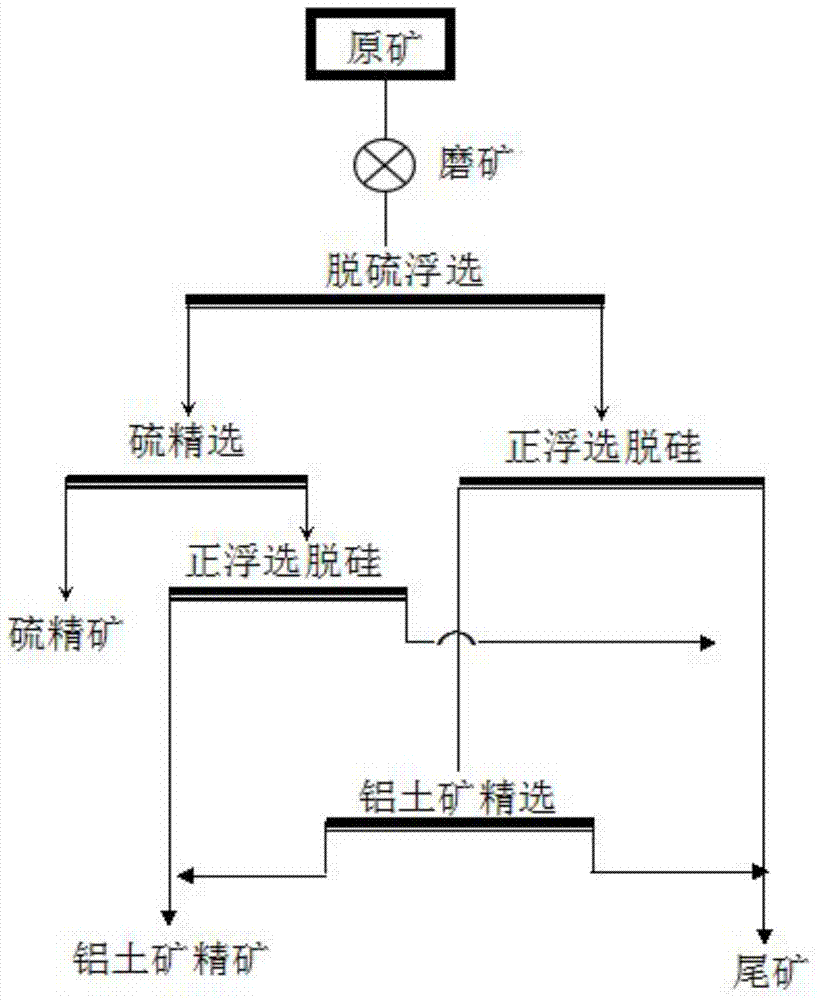

[0028] Such as figure 1 As shown, after raw ore grinding treatment, the ore powder after grinding is subjected to flotation desulfurization treatment, and the foam is scraped out to obtain coarse sulfur ore. The middle ore obtained in the second or second and third times returns to the first concentration for concentration treatment, and the foam will be obtained as sulfur concentrate; the middle ore of the first concentration is used as the desiliconization treatment step open middle ore; the bottom of the tank in the desulfurization treatment step, that is, the low-sulfur tailings is subjected to roughing, sweeping, etc., and the foam is used as sulfur concentrate, the substrate is low-sulfur tailings a, and the low-sulfur tailings Ore a is used as low-sulfur tailings a in the desiliconization treatment step; and then the open middle ore and low-sulfur tailings a are separately subjected to positive flotation desiliconization treatment, and after 1-2 times of coarseness, one...

Embodiment 2

[0041] A method for flotation desiliconization and desulfurization of sulfur-containing bauxite, comprising the following steps:

[0042] (1) Grind the raw ore through a grinder until the powder ore with a particle size of 210 mesh accounts for ≥90%, then place the powder ore in a flotation desulfurization tank, and add collectors and activators to it in sequence , foaming agent, and using a stirring speed of 100r / min stirring treatment for 30min, stop stirring, in the normal temperature environment, so that the flotation effect occurs in the flotation desulfurization tank, when there is foam on the surface of the flotation tank, the flotation The foam on the surface of the flotation cell is scraped off, and when the foam on the surface of the flotation cell no longer appears, the slurry in the bottom of the flotation cell is low-sulfur tailings; the foam scraped out is coarse sulfur ore;

[0043] (2) The rough sulfur ore obtained in step 1) is subjected to three times of bene...

Embodiment 3

[0053] A method for flotation desiliconization and desulfurization of sulfur-containing bauxite, comprising the following steps:

[0054] (1) Grind the raw ore through a grinder until the powder ore with a particle size of 200 mesh accounts for ≥90%, then place the powder ore in a flotation desulfurization tank, and add collectors and activators to it in sequence , foaming agent, and using a stirring speed of 90r / min to stir for 25min, stop stirring, in the normal temperature environment, the flotation effect occurs in the flotation desulfurization tank, when there is foam on the surface of the flotation tank, the flotation The foam on the surface of the flotation cell is scraped off, and when the foam on the surface of the flotation cell no longer appears, the slurry in the bottom of the flotation cell is low-sulfur tailings; the foam scraped out is coarse sulfur ore;

[0055] (2) The rough sulfur ore obtained in step 1) is subjected to three times of beneficiation, and after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com