Acid washing-free direct hot galvanizing method of hot-rolled strip steel

A hot-rolled steel strip and hot-dip galvanizing technology, which is applied in the field of metallurgy, can solve problems such as increased cost, reduced performance stability of galvanized layer, and reduced pickling operations, so as to eliminate environmental problems, increase the reduction ratio, and reduce waste acid The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

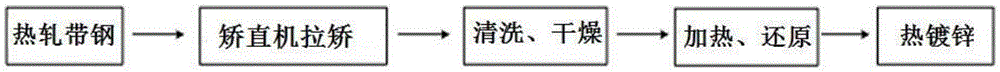

Method used

Image

Examples

Embodiment 1

[0035] The composition of the hot-rolled steel strip used is by weight percentage: C: 0.08%, Si: 0.01%, Mn: 1.4%, Cr: 0.10%, P: 0.015%, S: 0.01%, Nb: 0.01%, Ti: 0.01%, Al:0.01%, the balance is a slab of Fe and unavoidable impurities;

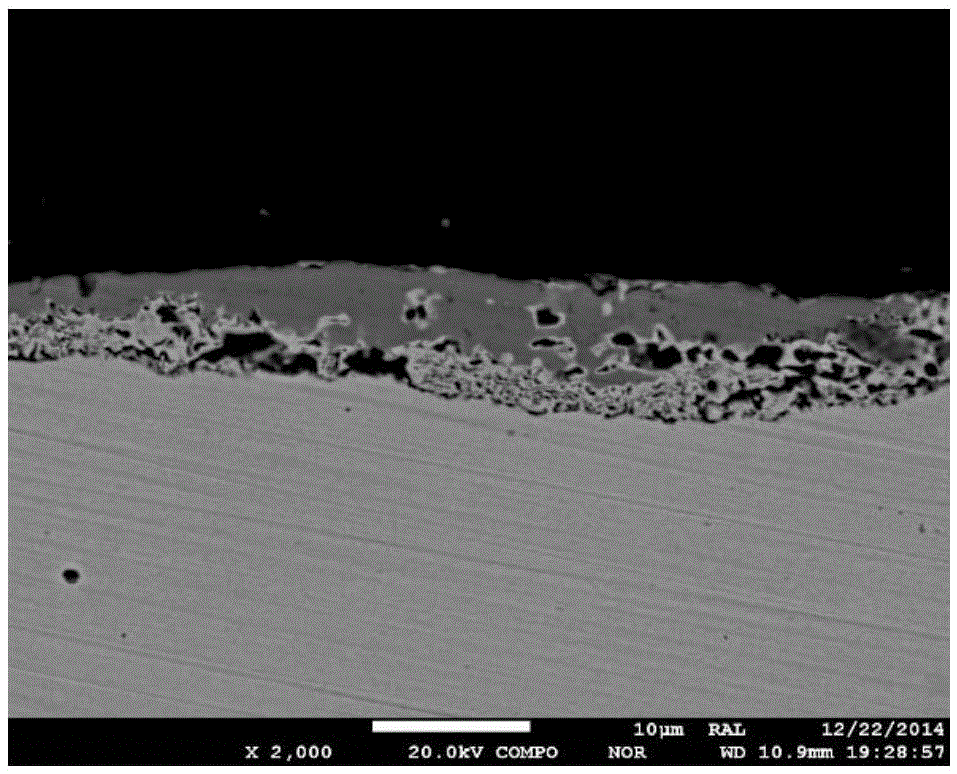

[0036] Heat the slab to 1220°C; control the starting temperature of finish rolling at 1000°C, control the temperature of finish rolling at 855°C, and the rolling speed during finish rolling is 7.6m / s; Flow cooling, the coiling temperature is controlled at 550°C; the thickness of the hot-rolled strip is 2mm, the thickness of the oxide scale is 8.9um, and the structure of the oxide scale is Fe 3 o 4 +Fe steel coil;

[0037] Straightening in a tensile leveler with an elongation of 3%;

[0038]In the heating furnace, heat the hot-rolled steel strip at a rate of 15°C / s to 900°C for reduction annealing. During the reduction annealing, the atmosphere of the heating furnace is 20% hydrogen and 80% nitrogen by volume; then hot-roll the strip After en...

Embodiment 2

[0041] The composition of the hot-rolled steel strip used is by weight percentage: C: 0.10%, Si: 0.1%, Mn: 1.6%, Cr: 0.3%, P: 0.01%, S: 0.001%, Nb: 0.008%, Ti: 0.01 %Al: 0.05%, the balance is a slab of Fe and unavoidable impurities.

[0042] Heat the slab to 1250°C; control the starting temperature of finish rolling at 1000°C, control the temperature of finish rolling at 855°C, and the rolling speed during finish rolling is 3.5m / s; Flow cooling, the coiling temperature is controlled at 550°C; the thickness of the hot-rolled strip is 2.5mm, the thickness of the oxide scale is 8.5um, and the structure of the oxide scale is Fe 3 o 4 +Fe steel coil;

[0043] Straightening in a tensile leveler with an elongation of 3%;

[0044] In the heating furnace, heat the hot-rolled strip steel at a rate of 20°C / s to 700°C for reduction annealing. During the reduction annealing, the atmosphere of the heating furnace is 10% hydrogen and 90% nitrogen in volume concentration; then hot-roll the...

Embodiment 3

[0047] The composition of the hot-rolled steel strip used is by weight percentage: C: 0.10%, Si: 0.3%, Mn: 2%, Cr: 0.5%, P: 0.006%, S: 0.001%, Nb: 0.005%, Ti: 0.01%, Al: 0.08%, the balance is a slab of Fe and unavoidable impurities;

[0048] Heat the slab to 1210°C; control the starting temperature of finish rolling at 1005°C, control the temperature of finish rolling at 860°C, and the rolling speed during finish rolling is 4.0m / s; Flow cooling, the coiling temperature is controlled at 560°C; the thickness of the hot-rolled strip is 2.1mm, the thickness of the oxide scale is 8.5um, and the structure of the oxide scale is Fe 3 o 4 +Fe steel coil;

[0049] Straightening in a tensile leveler with an elongation of 3%;

[0050] In the heating furnace, heat the hot-rolled steel strip at a rate of 30°C / s to 800°C for reduction annealing. During the reduction annealing, the atmosphere of the heating furnace is 10% hydrogen and 90% nitrogen by volume; then hot-roll the strip Enter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com