High-strength high-conductivity Cu-Mg alloy and preparation method thereof

A high-conductivity, high-strength technology, applied in the field of high-strength and high-conductivity copper-magnesium alloys and their preparation, can solve the problems of high electrical conductivity, low elongation, low strength and high temperature softening resistance, and achieve electrical conductivity High and high temperature softening ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

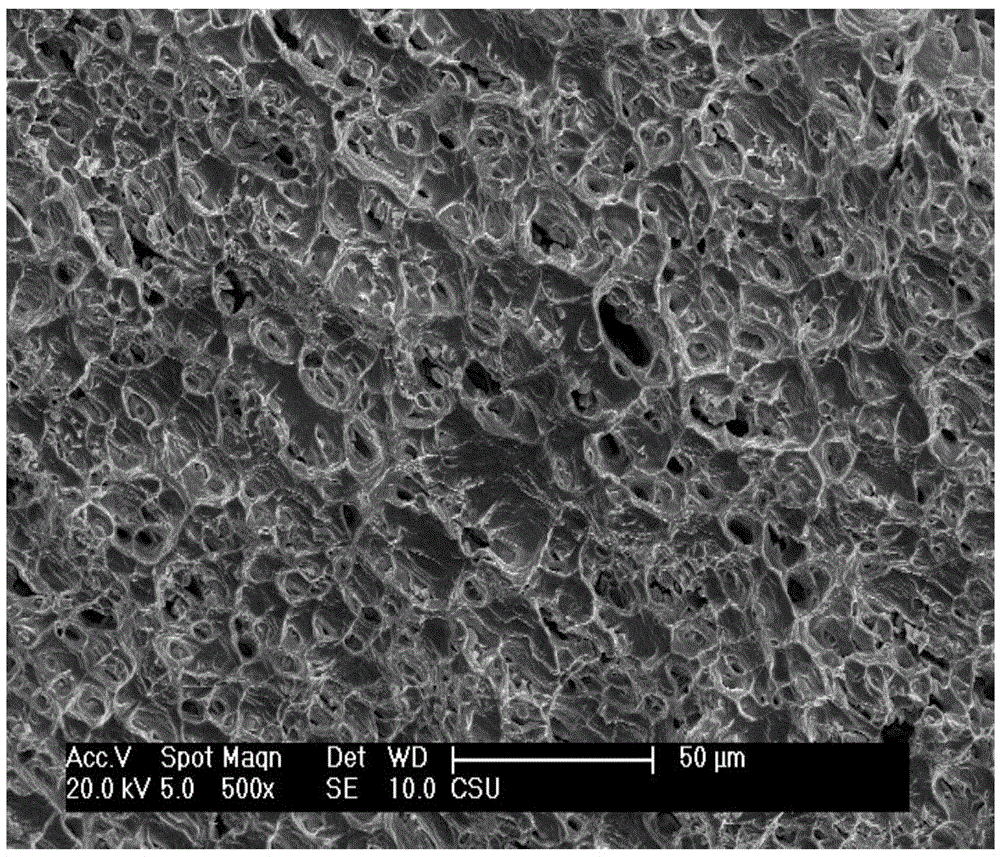

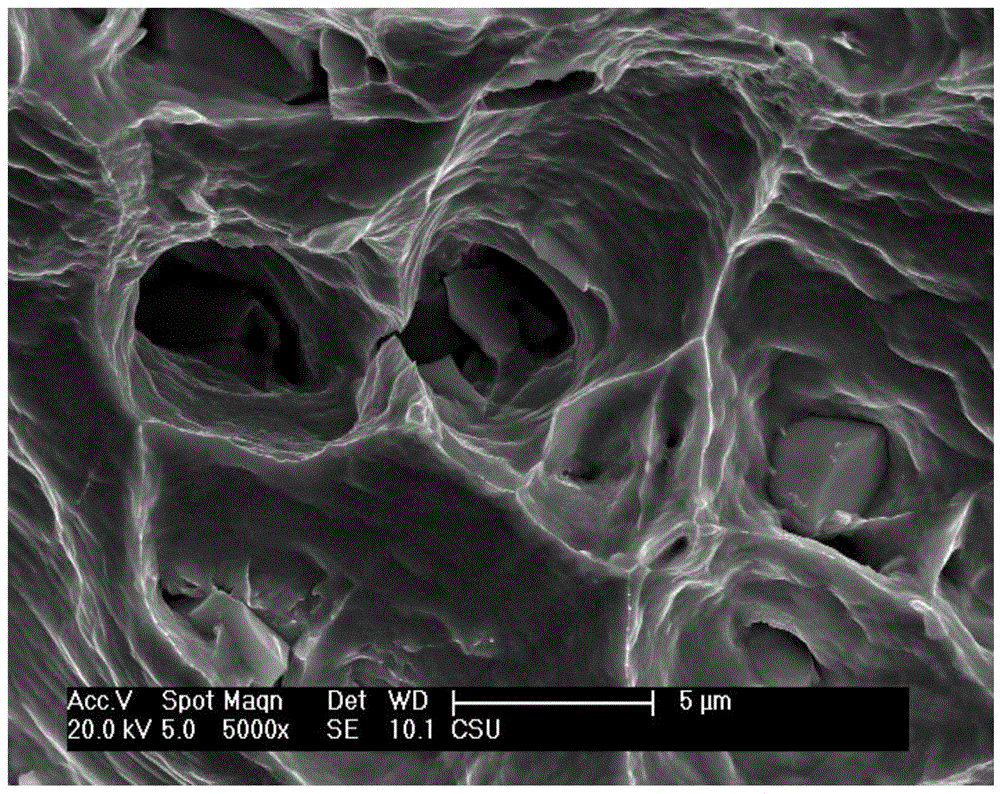

Image

Examples

Embodiment 1

[0034] The alloy composition is Mg: 0.2wt%; Ca: 0.1wt%; B: 0.005wt%; the balance is Cu and unavoidable impurities.

[0035] The specific process steps include:

[0036] (1) Melting to prepare CuMgCaB alloy melt

[0037] Electrolytic pure copper, pure magnesium, Cu-Ca master alloy and Cu-B master alloy are used as raw materials. After all raw materials are baked and dried, they are smelted in a non-vacuum induction melting furnace. The melting and feeding sequence is as follows:

[0038] Add electrolytic pure copper for charging → add calcined charcoal covering agent → heat up to 1200°C-1250°C → melt → control furnace temperature at 1100-1120°C, add pure magnesium → melt → control furnace temperature at 1020-1060°C, add Cu- B master alloy→melting→control furnace temperature at 1020-1060℃, add Cu-Ca master alloy→melt→add cryolite and calcium fluoride, stir to remove slag. CuMgCaB alloy melt is formed after melting;

[0039] (2) Semi-continuous casting

[0040] The CuMgCaB al...

Embodiment 2

[0053] The alloy composition is Mg: 0.2wt%; Ca: 0.3wt%; B: 0.005wt%; the balance is Cu and unavoidable impurities. According to the processing steps of steps (1)-(7) of Example 1, a plate with a thickness of 10mm is made. Wherein in step (2), the casting speed is 5m / h, and the cooling water pressure is 0.06MPa; in step (4), the cold drawing pass deformation is 20%, and the total deformation is 80%; in step (5), intermediate annealing The temperature is 700° C., and the time is 1 h; the cold finish drawing deformation in step (6) is 20%; the annealing temperature of the finished product in step (7) is 720° C., and the time is 1 h. The measured properties of the plate are as follows: tensile strength σ b =510MPa, electrical conductivity g=78.9% IACS, elongation δ=8.1%.

Embodiment 3

[0055] The alloy composition is Mg: 0.6wt%; Ca: 0.3wt%; B: 0.005wt%; the balance is Cu and unavoidable impurities. According to the processing steps of the steps (1)-(7) of Embodiment 1, a plate with a thickness of 10mm is made. Wherein in the step (2), the casting speed is 5m / h, and the cooling water pressure is 0.06MPa; in the step (4), the deformation of the cold rolling pass is 20%, and the total deformation is 80%; in the step (5), the intermediate annealing temperature 700°C for 1 hour; in step (6), the cold finish rolling deformation is 20%; in step (7), the finished annealing temperature is 720°C, and the time is 1 hour. The measured properties of the plate are as follows: tensile strength σ b =544MPa, electrical conductivity g=75.2% IACS, elongation δ=7.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com