A method for preparing graphene microsheets using a counter-jet jet mill

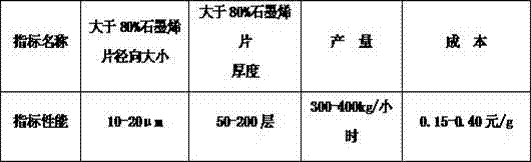

A technology of graphene microchips and jet mills, which is applied in the direction of graphene and nano-carbon, can solve the problems of complex preparation process, small output, and high production cost of graphene, and achieve uniform dispersion, low production cost, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of method that utilizes counter-jet jet mill to prepare graphene microsheets:

[0031] (1) Mix 80 parts by weight of expanded graphite powder, 1 part by weight of talc powder, and 0.5 parts by weight of dimethylacetamide in a high-speed mixing reactor at a heating temperature of 250 ° C, at 300 rpm Stir and disperse for 30-60 minutes at a certain speed to obtain a mixed powder;

[0032] (2) Prepare the intercalation agent with ferric chloride, potassium chloride, and polyethylene glycol at a mass ratio of 2:2:1, and then soak the mixed powder obtained in step (1) in the intercalation agent for more than 48 hours, Filter and dry by centrifuge to obtain pre-intercalation powder;

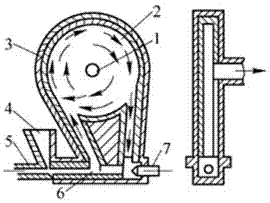

[0033] (3) Feed the pre-intercalation powder obtained in step (2) into the jet-jet pulverizer, which is equipped with two nozzles, one pulverization nozzle sprays into the pulverization chamber at a pressure of 3.0 MPa, and one The feeding nozzle is sprayed into the crushing chamber wit...

Embodiment 2

[0035] A kind of method that utilizes counter-jet jet mill to prepare graphene microsheets:

[0036] (1) Mix 90 parts by weight of highly oriented graphite powder, 5 parts by weight of talc powder and 1.5 parts by weight of dimethylacetamide in a high-speed mixing reactor at a heating temperature of 300 ° C, to Stir and disperse at a speed of 600rpm for 30min to obtain a mixed powder;

[0037] (2) Prepare the intercalation agent with ferric chloride, potassium chloride, and polyethylene glycol at a mass ratio of 3: 3:1, and then soak the mixed powder obtained in step (1) in the intercalation agent for more than 48 hours, Filter and dry by centrifuge to obtain pre-intercalation powder;

[0038] (3) Feed the pre-intercalation powder obtained in step (2) into the jet-jet pulverizer, which is equipped with two nozzles, one pulverization nozzle sprays into the pulverization chamber at a pressure of 4.0 MPa, and one The feeding nozzle is sprayed into the crushing chamber with a pr...

Embodiment 3

[0040] A kind of method that utilizes counter-jet jet mill to prepare graphene microsheets:

[0041] (1) Mix 85 parts by weight of flake graphite powder, 3 parts by weight of talc powder and 0.8 parts by weight of dimethylacetamide in a high-speed mixing reactor at a heating temperature of 260°C, and mix at 400rpm Stir and disperse at a rotating speed of 45min to obtain a mixed powder;

[0042] (2) Prepare the intercalation agent with ferric chloride, potassium chloride, and polyethylene glycol at a mass ratio of 2.1:2.5:1, and then soak the mixed powder obtained in step (1) in the intercalation agent for more than 48 hours, Filter and dry by centrifuge to obtain pre-intercalation powder;

[0043] (3) Send the pre-intercalation powder obtained in step (2) into the jet mill of the jet jet, which is equipped with two nozzles, one of which sprays into the pulverization chamber at a pressure of 3.6 MPa, and one of the jet jet mills. The feeding nozzle is sprayed into the crushin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com