A kind of strontium, iron doped hydroxyapatite collagen fiber composite scaffold material and preparation method

A technology of hydroxyapatite and collagen fibers, which is applied in the fields of iron compounds, chemical instruments and methods, medical science, etc., to achieve the effects of repairing and treating bone defects, improving mechanical strength, and good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

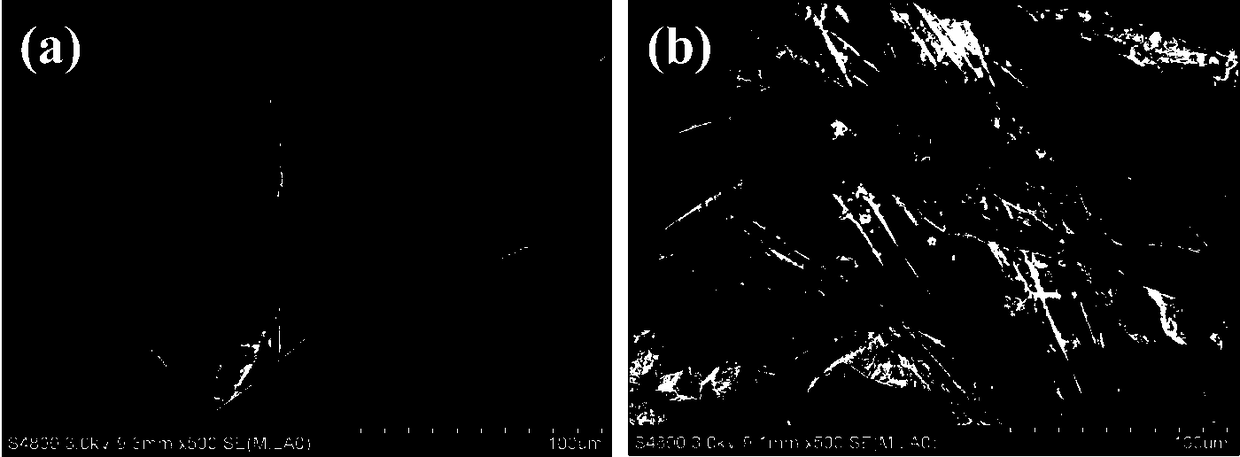

Image

Examples

Embodiment 1

[0030] (1) Weigh 4gSr(NO 3 ) 2 , 61gFeCl 3 ·6H 2 O, added to 200mL deionized water, added to deionized water, magnetically stirred to dissolve; after it was completely dissolved, added to 250mL 60% sodium carbonate solution, controlled temperature at 35°C, stirred to make it co-precipitate, and then ultrasonicated for 10 min, vacuum filtration, and then put the filter cake in a blast drying oven, and dry at 90°C for 24 hours to obtain a precursor powder; weigh 1.0g NaCl and mix it with the precursor powder, grind it evenly and place it in a muffle furnace, The speed of ℃ / min is raised to 900 ℃, and calcined for 6 hours to obtain SrFe 12 o 19 powder.

[0031] (2) Weigh 5.54g of calcium chloride and add it to deionized water to dissolve, and make a solution of 0.3mol / L, adjust the pH of the solution to 10 with ammonia water, and then add 5.0g of SrFe prepared in step (1) 12 o 19 Powder, stir evenly at room temperature; weigh 3.95g ammonium hydrogen phosphate and add it to...

Embodiment 2

[0035] (1) The same as described in Example 1.

[0036] (2) Weigh 11.08g of calcium chloride and add it to deionized water to dissolve, and make a solution of 0.3mol / L, adjust the pH of the solution to 10 with ammonia water, and then add 5.0g of SrFe prepared in step (1) 12 o 19 Powder, stir evenly at room temperature; weigh 7.91g of ammonium hydrogen phosphate and add it to deionized water to dissolve, adjust the pH of the solution to 10 with ammonia water, slowly add it to the above mixed solution containing calcium chloride at room temperature, continue to stir for 1 hour, and let it stand for 12 hours , then washed with deionized water and ethanol, dried at 80°C for 24 hours to obtain strontium and iron doped hydroxyapatite, and ball milled the prepared strontium and iron doped hydroxyapatite at a speed of 300 r / min for 10 hours, and set aside .

[0037] (3) The same as described in Example 1.

Embodiment 3

[0039] (1) The same as described in Example 1.

[0040] (2) Weigh 16.61g of calcium chloride and add it to deionized water to dissolve, and make a solution of 0.3mol / L, adjust the pH of the solution to 10 with ammonia water, and then add 5.0g of SrFe prepared in step (1) 12 o 19 Powder, stir evenly at room temperature; weigh 11.86g of ammonium hydrogen phosphate and add it to deionized water to dissolve, adjust the pH of the solution to 10 with ammonia water, slowly add it to the above mixed solution containing calcium chloride at room temperature, continue stirring for 1 hour, and let it stand for 12 hours , then washed with deionized water and ethanol, dried at 80°C for 24 hours to obtain strontium and iron doped hydroxyapatite, and ball milled the prepared strontium and iron doped hydroxyapatite at a speed of 300 r / min for 10 hours, and set aside .

[0041] (3) The same as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com