Shape memory type high-elasticity activity nano-fiber stent and application thereof

A nanofiber and high elasticity technology is applied in the field of preparation of bioabsorbable shape memory biomaterials, which can solve the problems of mismatched biomechanical properties, insufficient biocompatibility and anticoagulation, and achieve the effect of good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) The linear elastic polyester PCT8-2 that takes 2g is dissolved in the dichloromethane of 18g with electronic balance: in the mixed solvent of hexafluoroisopropanol=50:50, stirs until dissolving completely, obtains linear elastic polyester PCT8 -2 PCT8-2 spinning solution with a final concentration of 10% (w / w).

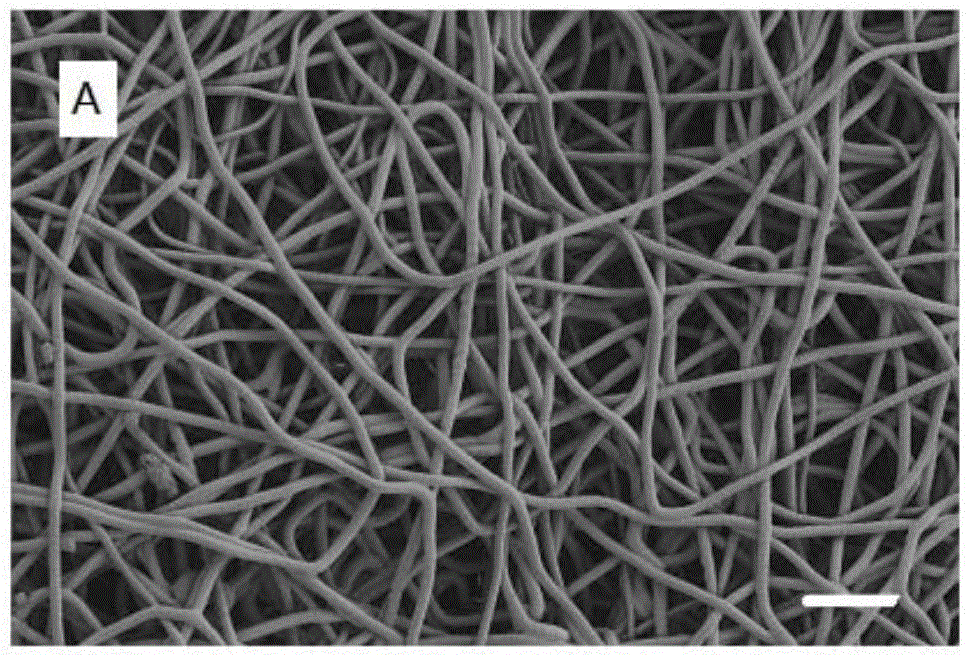

[0065] (2) Select a 5mL syringe and a needle with an inner diameter of 1.2mm to extract the PCT8-2 spinning solution with a concentration of 10% (w / w) obtained in step (1), and fix it on the electrospinning device for electrospinning , the process parameters are: the spinning solution injection rate is 2mL / h, the voltage is 15kV, the receiving distance is 20cm, the ambient temperature is 22°C, and the ambient relative humidity is 40%. Aluminum foil was used as the receiving device, and the fiber membrane was spun for 2 hours, and the collected fiber membrane was dried in a vacuum oven at room temperature for 24 hours to obtain a shape-memory highly elastic ...

Embodiment 2

[0068] (1) Dissolve 2g of linear elastic polyester PCT9-1 with an electronic balance and dissolve it in 16g of DMF: trifluoroacetic acid=50:50 mixed solvent, stir until completely dissolved to obtain the final concentration of linear elastic polyester PCT9-1 It is 8% (w / w) PCT9-1 spinning solution.

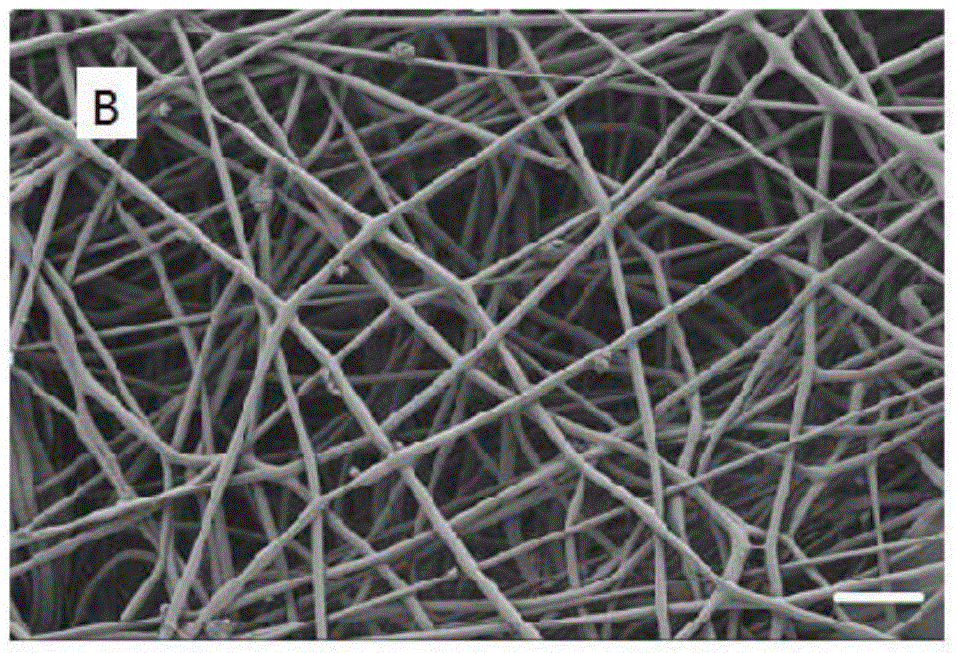

[0069] (2) Select a 5mL syringe and a needle with an inner diameter of 1.2mm to extract the PCT9-1 spinning solution with a concentration of 8% (w / w) obtained in step (1), and fix it on the electrospinning device for electrospinning , the process parameters are: the spinning solution injection rate is 2mL / h, the voltage is 15kV, the receiving distance is 20cm, the ambient temperature is 22°C, and the ambient relative humidity is 40%. Using aluminum foil as a receiving device, spinning for 2 hours, the collected fiber membrane was dried in a vacuum oven at room temperature for 24 hours to obtain a shape-memory highly elastic active nanofiber scaffold (PCT9-1).

[0070] The scannin...

Embodiment 3

[0071] Example 3: Heparin Coaxial Spinning Stent Loaded with Growth Factors

[0072] (1) Take 2g of linear elastic polyester PCT8-2 with an electronic balance and dissolve it in 16g of dimethyl sulfoxide: trifluoroacetic acid=50:50 mixed solvent, stir until completely dissolved to obtain linear elastic polyester PCT8 -2 PCT spinning dope A with a final concentration of 8% (w / w), as the core layer for coaxial spinning.

[0073] (2) 400 mg of heparin, 600 mg of type I collagen and 1000 mg of linear elastic polyester PCT8-21000 mg are dissolved in 16 g of hexafluoroisopropanol to obtain linear elastic polyester PCT8-2 with a final concentration of 8% (w / w). Dope B of heparin / collagen / elastic polyester was used as the sheath for coaxial spinning.

[0074] (3) Using coaxial spinning needles, the two kinds of spinning solutions were fixed on the electrospinning device through different syringe pumps for electrospinning. The process parameters were: the advancing speed of the shell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com